15

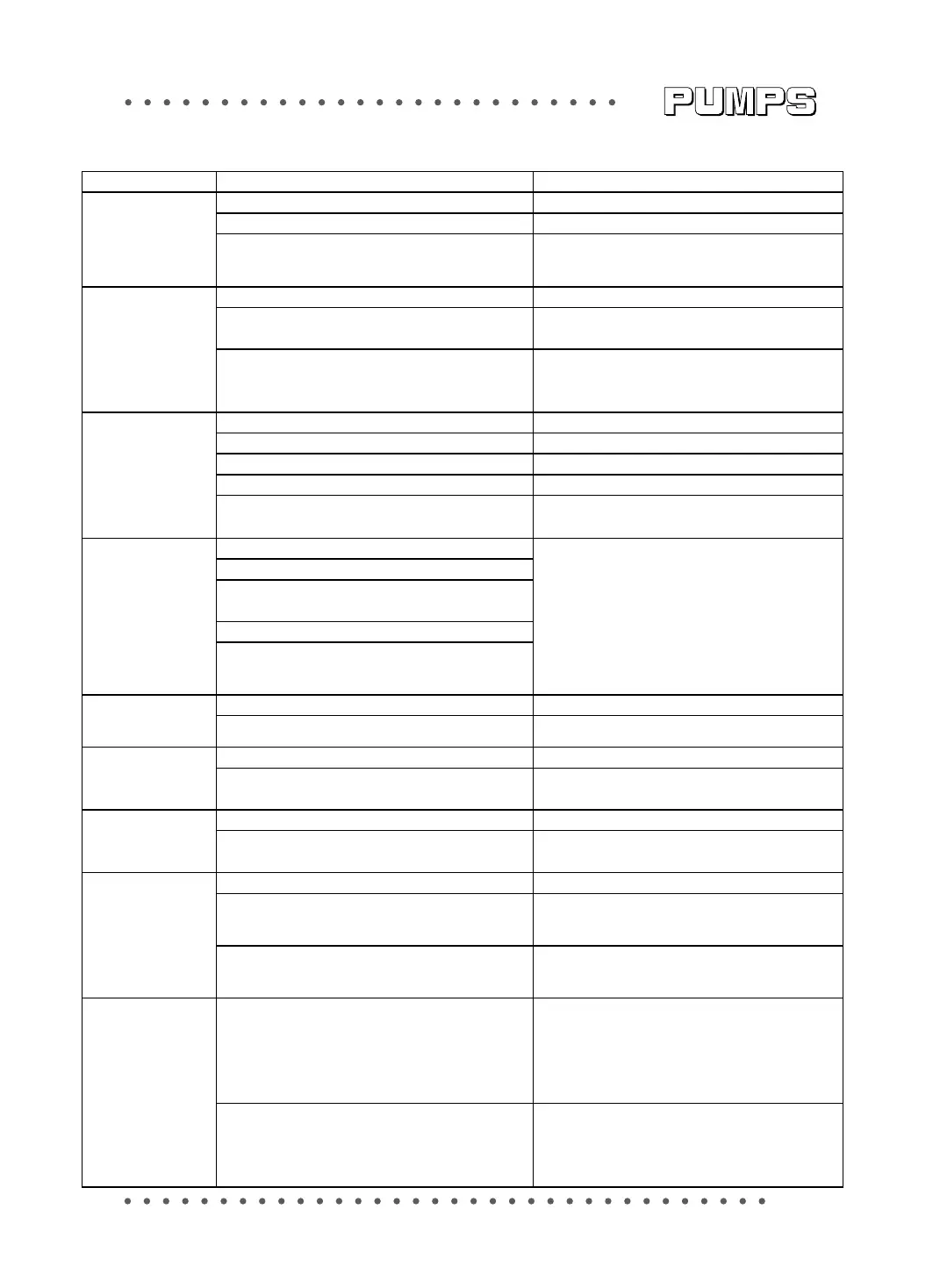

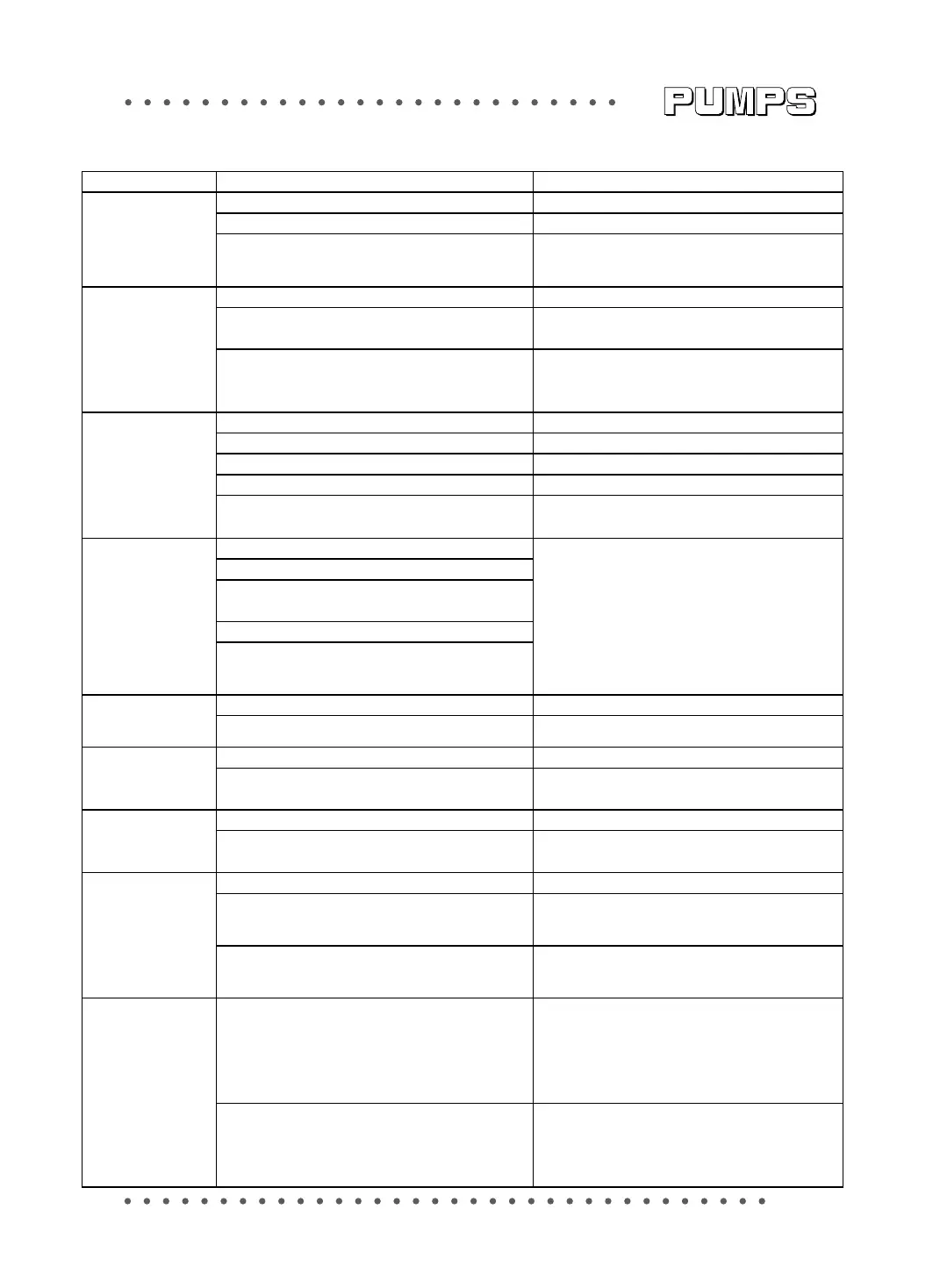

5. Trouble shooting

Trouble Possible Cause Remedy

Motor doesn’t No

power. Check the

power supply.

work.

Motor burnout. Recoil the motor

No power. Check the power supply.

Electromagnetic switch turns off the

pump.

Checking whether motor is overloaded;

If the switch is not working correctly,

Self-priming is too

slow.

Outlet is blocked. Check outlet pipe.

Water level in pump is not high

enough.

Fill pump up with liquid.

It is sucking air. Make sure there is no inltration of air

through the inlet, and that the water level is

high enough.

There is not

enough

Pressure in the

outlet.

It is sucking air. Check the inlet pipe.

Inlet is blocked. Clean the inlet.

Impeller blade is worn. Install a new impeller.

Direction of motor operation is wrong. Change the contact lines of the motor.

Seal leaks. Use a new seal.

Pump leaks due

to dry running.

Water level controller is incorrectly installed. Adjust water level controller.

Replace damaged parts with

new ones.

There is no liquid in the inlet.

The pump is left running after outlet is

blocked.

Inlet pipe leaks.

Water-level is not high enough

and pump can’t self-prime.

Loud sounds and

excess vibrations.

Motor shaft is loosened. Fasten the shaft.

Bearing is damaged. Replace bearing.

Seal leaks. Seal damaged. Replace the seal.

Seal packing damaged. Check whether the material is suitable for

the liquid.

Water at the inlet

but no pressure at

the outlet.

Inlet blocked. Remove sludge.

Air is being sucked in. Make sure there isn’t any leakage.

Crack on the

pump body.

Material not proper for the solution. Choose proper material.

Inlet pipe is not fastened. Fasten the inlet pipe and replace

damaged pipe with new one.

Long-term dry running makes the solution

very hot, and the pump exploded.

Replace damaged parts with new ones

and operate properly.

Motor is too hot. The motor is about to overload. Check whether the power is too high for the

motor, reduce the diameter of

Impeller or increase the power of motor.

The voltage is not steady,

Sometimes too high, sometimes too low.

Use a power stabilizer or surge protector to

protect the motor.

Loading...

Loading...