Installation & Operation Manual

O-360 and IO-360 Series Engines

© March 2004 Superior Air Parts Inc. Chapter 6 • Normal Operating Procedures

3

OPERATION INSTRUCTIONS CONTINUED

A. Preflight - Before starting the aircraft engine

for the first flight of the day, perform a Daily Pre-

Flight Inspection. Refer to Chapter Five, Section

5. Daily Pre-Flight Inspection.

B. Starting Procedures - The following

starting procedures are recommended,

however, the starting procedures for different

installations will require some variation from

these procedures. Refer to your airframe

operator's manual.

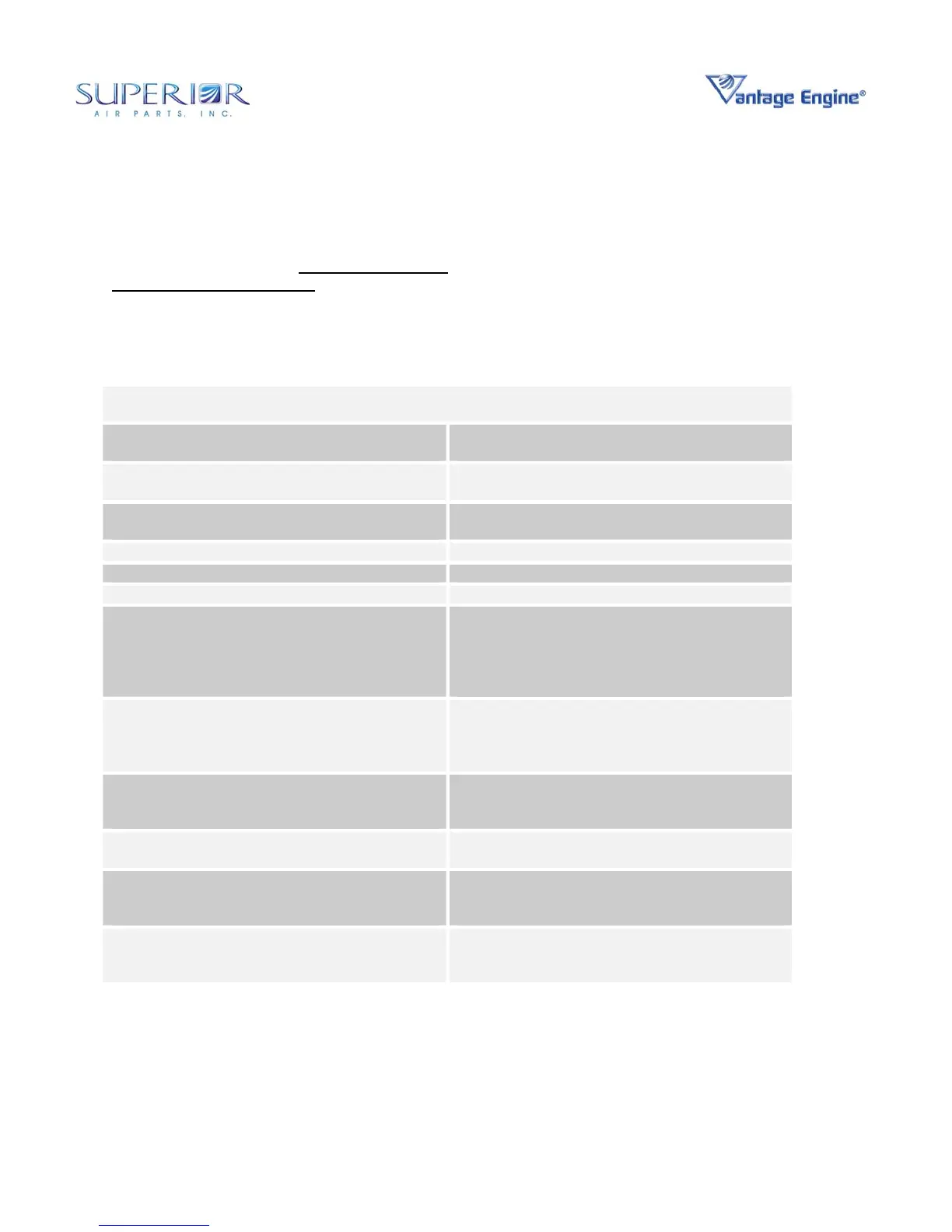

Table 6-1 • Normal Starting Procedures

Engine Equipped With

Float Type Carburetors

Engines Equipped With

Fuel Injectors

1. Set Carburetor heat control in the “Off”

position.

1. Set propeller governor control in the “Low

Pitch, Full RPM” position (where applicable).

2. Set propeller governor control in the “Low

Pitch, Full RPM” position (where applicable

2. Turn fuel valves “On”

3. Turn fuel valves “On” 3. Open throttle approximately ¼ travel.

4. Move mixture control to “Full Rich” 4.Turn on Master Switch

5. Turn on Master Switch 5. Turn on Boost Pump

6. Turn on Boost Pump (if installed) 6. Open throttle to wide open. Move mixture

control to “Full Rich” until a slight but steady

fuel flow is noted (approximately 3 to 5

seconds). Return mixture control to “Idle Cut-

off”.

7. Open throttle approximately ¼ travel.

Prime with 1 to 3 strokes of manual priming

pump or activate electric primer for 1 to 2

seconds.

7. Set magneto selector switch (consult

airframe manufacturer’s handbook for correct

position).

8. Set magneto selector switch (consult

airframe manufacturer’s handbook for correct

position.

8. Engage Starter.

9. Engage Starter 9. Release starter when engine fires. If both

magnetos are not on, switch to “Both”

10. Release starter when engine fires, open

throttle slightly to keep the engine running. If

both magnetos are not on, switch to “Both.”

10. Move mixture control slowly and smoothly

to “Full Rich” and retard the throttle to desired

idle speed.

11. Check oil pressure gage. If minimum oil

pressure is not indicated within thirty seconds,

stop engine and troubleshoot

11. Check oil pressure gage. If minimum oil

pressure is not indicated within thirty seconds,

stop engine and troubleshoot

HOT STARTS USE THE SAME PROCEDURE AS A NORMAL START

WITH THE EXCEPTION OF PRIMING – OMIT PRIMING

Loading...

Loading...