9

LEVELING THE MACHINE

The machine must be leveled when it is installed. Balancing the machine horizontally protects the

needle from moving out of position.

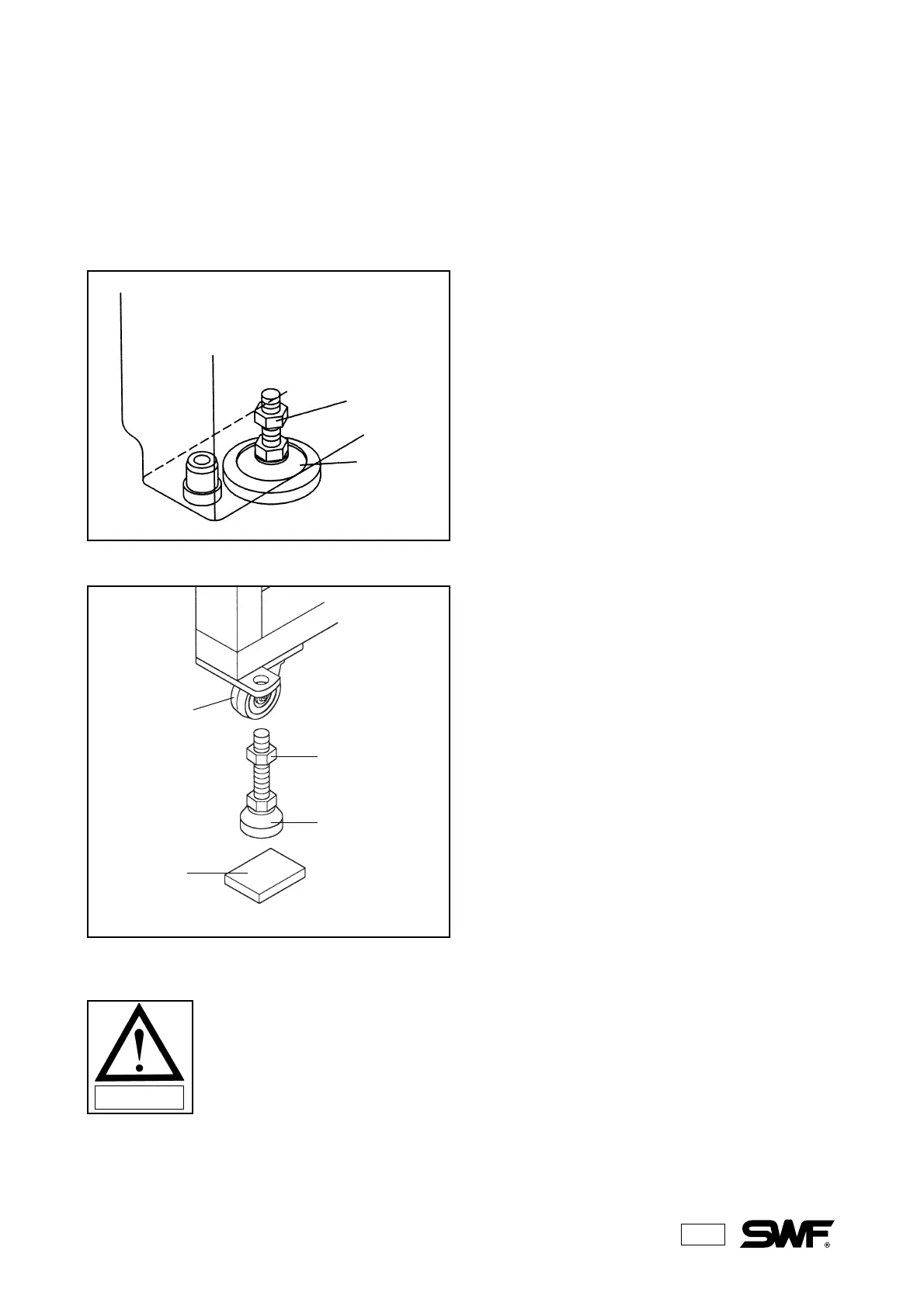

Nut

Adjusting

bolt

Nut

Adjusting bolt

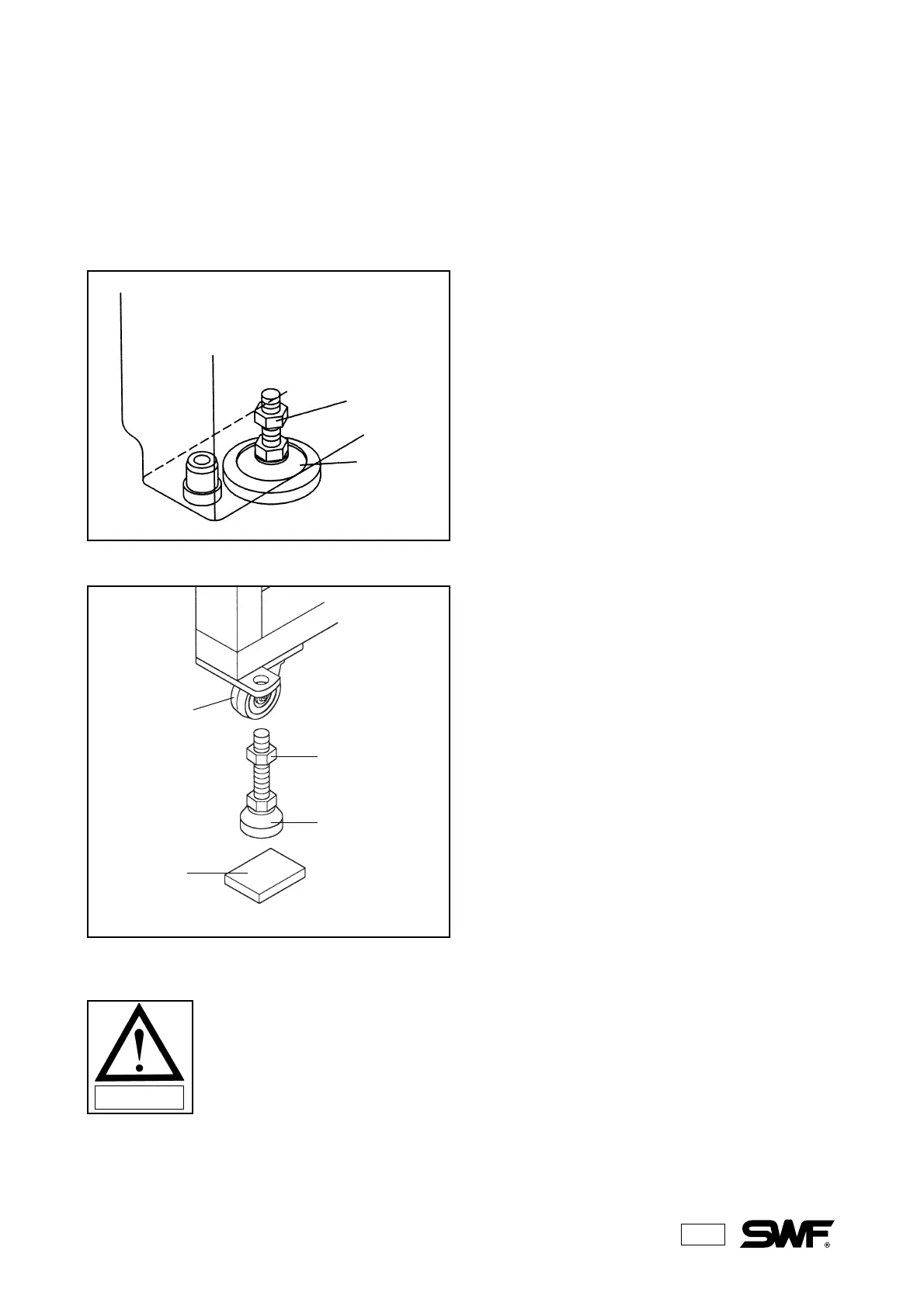

Rubber

Caster

1) When there is no stand attached. adjust the front,

rear, left and right of the machine using the level

adjusting bolt. When the machine is level,

tighten the fixing nut.

2) When there is a stand attached, insert the four

horizontally adjusting bolts into the holes on the

stand. Then place the four rubber mats (for

vibration prevention) under each of the bolts.

Adjust the bolts until the caster is raised above

the level of the floor. Use a level to adjust the

machine using the horizontally adjusting bolts so

that the machine is level on all four sides. When

the machine is level, tighten down the fixing

nuts.

CAUTION

1) The machine must be balanced horizontally in all four directions : front, back, left and

right.

2) If the height of the four adjusting bolts varies over 10mm, use spacers beneath the

lower bolts to make the heights even.

Loading...

Loading...