20

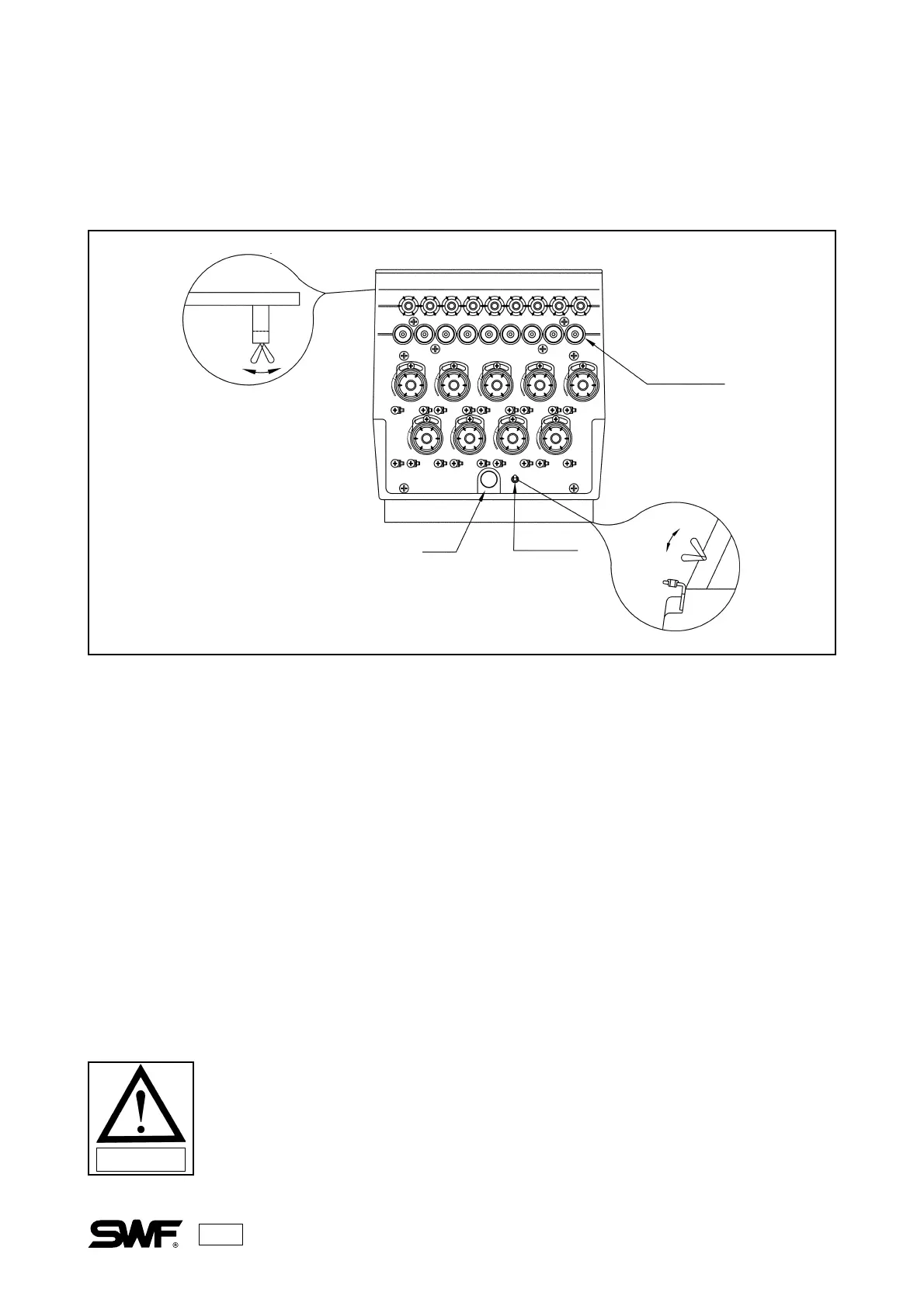

ON/OFF BUTTON ON THREAD TENSION ADJUSTMENT

BOARD

For normal operation, press the ON/OFF button or throw the toggle switch to turn the machine on The light

will indicate that the machine is on. If you have a button, the light is in the button; if you have a toggle

switch, it is below the toggle switch

When the machine stops after a thread break is detected, you can move the frame backward to the location

of the thread break using the STOP button, and start the machine again to pick up the stitching. This is

essentially an edit of the design.

If you want to back the machine up for any reason when a thread break has NOT occurred, you must press

the ON/OFF switch twice. When the light is blinking, you can back up the machine to the desired location.

When an upper or lower thread break is detected the light on the head blinks. After fixing the thread and

backing up to the point of the break, press the START button to start stitching again.

On multi-head machines, you can turn one or more heads off by throwing the toggle switch to the off

position or pressing the ON/OFF button until the light goes off.

NOTICE

The take-up lever continues to operate even when the head is turned off. This

movement can cause the needles to become unthreaded. A rubber magnet bar

can be used to prevent the thread from pulling out of the needle.

Toggle Switch

Lamp

ON

ON

OFF

OFF

Thread detection

delete

Thread detecting roller

Loading...

Loading...