Syntace GmbH · Dammweg1 · 83342 Tacherting · Germany · Tel. +49 (0)8634-66666 · Fax: +49 (0)8634-6365 · E-Mail: syntace@syntace.de · www.syntace.de

TIP: FOR ALUMINUM SEATPOSTS

• Apply a little mounting paste onto seatpost. You can prevent sti-

cking that way.

Pic. 1

Important: The seat post has to in-

serted at least to the marking „mi-

nimum insert“.

Caution: In many frames the seatpost

has to be inserted even further, usu-

ally at least to the lower edge of the

top tube. If the seatpost is not being

inserted far enough, the frame and/or

the seatpost can be damaged.

CAUTION FOR CARBON SEATPOSTS: Please ensure the

seatpost clamping mechanism (frame and seat postclamp) are

suitable for carbon seatposts. Not permitted are for example

clamping mechanisms that apply an asymmetrical clamping

force causing the post to be highly stressed at one point. The

Syntace P6 seatpost can also NOT be used with seat clamps

touching the seatpost. If this happens, the seatpost could be

damaged and could possibly break! In case you have a clamp

touching the post, exchange for a different model such as the

Syntace SuperLock. If you are not certain please contact the

respective manufacturer.

• Tighten the clamp just enough so you cannot turn the seat

anymore.

Shortening seatpost

If you do not use the entire length of your seatpost, it can be shor-

tened to save some unnecessary weight. Please only shorten the post

when you have determined your maximum seat post height.

• First measure the min. insert length of the post as well as the

distance from the top of your seat tube to bottom of the top tube

of your frame. The larger of the two values will be your min. insert

length for the seatpost in the respective frame. The additional

length of the seatpost which remains in the seat tube when the post

is at your own personal (maximum) height, can be sawed off.

• To saw-off, carefully place the post in a vice with V-clamps. If pos-

sible, clamp the end which will be removed anyway.

• Please use a fine metal saw blade to cut the carbon post and use a

fine sand paper to deburr. You can protect the cutting surface from

fraying by applying a clear coat or superglue.

ATTENTION: Fine carbon particles are a health hazard. Please

do not breath in or vacuum up with a vacuum cleaner. It is best

to clean up with a wet paper towel. The metal saw blade will no

longer be good for cutting metal but can be used if you need to

cut carbon again in the future.

Installation of seat

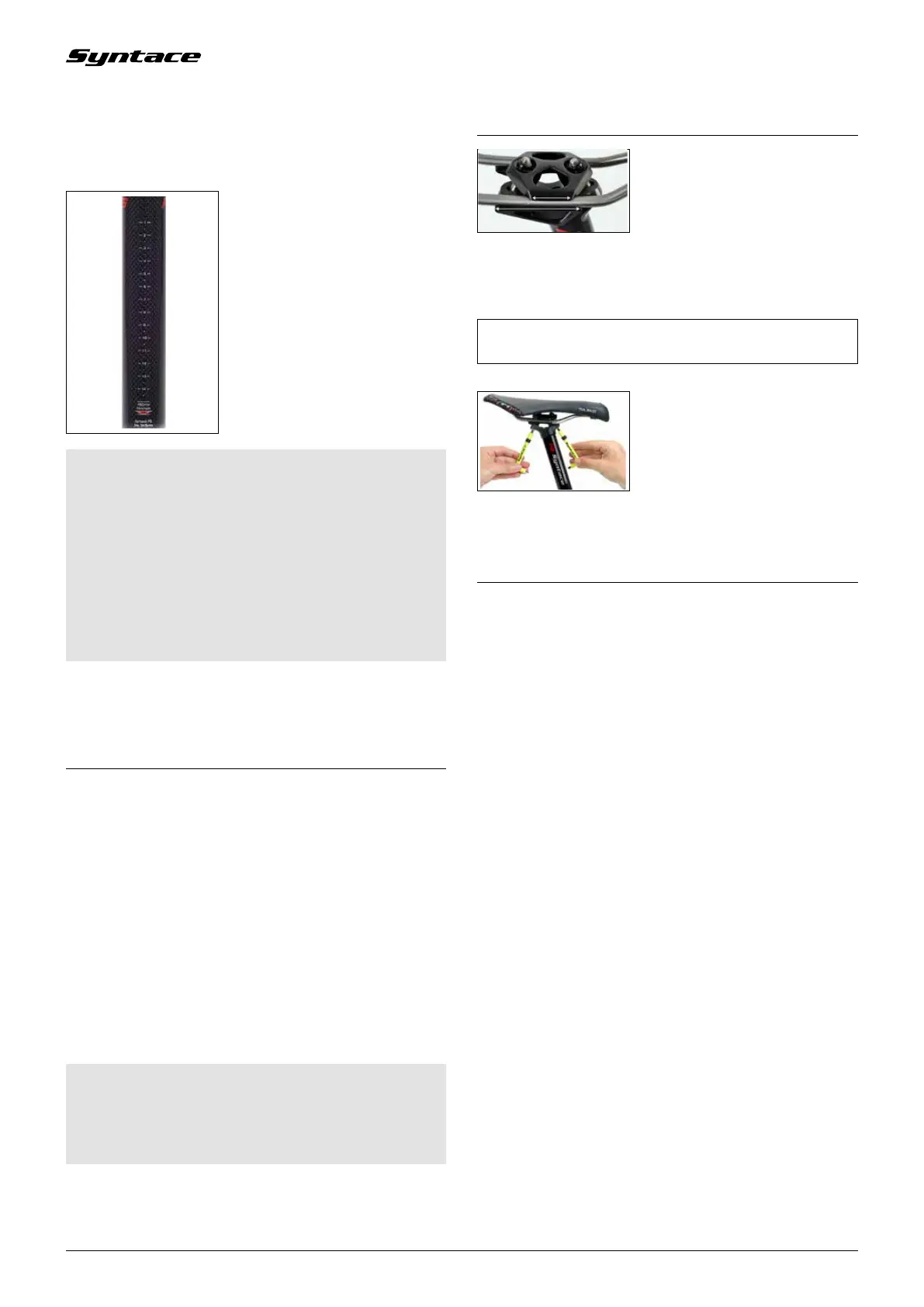

Pic. 2

The clamp for the seat is suited for

standard 7 mm rails, as well as for

Carbon rails with an oval cross section

with height of up to 11mm (Pic. 2).

• Loosen both clamping screws until the threads disappear in the

nuts. It is not necessary to completely unscrew the clamping

screws.

TIP: First adjust the tilt and then the horizontal position of the

seat.

Pic. 3

• Tighten the clamping screws alterna-

ting and in steps up to a torque value

of 6 to max. 8 Nm (Pic. 3)

• Try to move seat vigorously and

retighten.

• After 1-2 hours of use, retighten to

prescribed torque. Regularly check

for tightness.

Care, maintenance and safety

Proper maintenance and care will ensure a long life and reliable

function of your Syntace products. Please follow these simple steps

to maintain your system:

• Check the inside of your Syntace seatpost regularly for moisture

and remove if found.

• To prevent dirt from entering the seat tube, we recommend using

a seatpost clamp with a wiper seal (such as the Syntace SuperLock)

and/or an additional wiper device (such as the Syntace Little Joe).

• Check screws for proper torque regularly.

• Check the seatpost regularly for signs of fatigue (discoloration,

cracks and dents, for example).

• Warning: Upon longer exposure, brake fluid may attack epoxies and

resins as well as other coatings used in carbon components (Brake

fluid is highly deliquescent). Therefore, if brought into contact with

any carbon component please ensure that the affected area is

thoroughly cleaned with water to avoid any damage.

• Should the Syntace aluminum seatpost be bent due to a crash:

Never attempt to straighten it! Contact your dealer or Syntace to

arrange for replacement.

• Attention: please take note of the seatpost’s wear limit. When

frequently adjusting the height of your seatpost in muddy or dusty

conditions, material wear actually takes place on the surface of

both the seat tube and seatpost. The wear on carbon seatposts is

much higher than on alloy seatposts due to the coated resin matrix/

fibers used. To keep this wear to a minimum, we recommended re-

moving the seatpost from the frame after every ride in wet/muddy

conditions and then to clean it. The inside of the seat tube should

also be cleaned with a rag. Check the diameter of the seatpost from

time to time. At no position along the post, the diameter is allowed

to become less than 0.2 mm than the nominal specified diameter of

the seatpost! If this is the case, the seatpost requires replacing to

prevent the frame from being crushed resulting in possible defor-

mation or cracking in the clamping area.

Loading...

Loading...