7

Doument in original language

GB

- service is not carried out on a fan that is in operation and unless

the impeller is stationary.

- applicable health and safety regulations are followed (EN50 110,

IEC 364).

- cleaning with fluids when the fan is connected to voltage

can cause an electric shock – danger to life!

- under no circumstances may a high pressure cleaner or

water jet be used.

- no aggressive solvents may be used as cleaning agents.

- the cleaning interval is in proportion to how fast the impeller

becomes dirty.

- cleaning is of the fan's through flow area.

- if the motor protection has tripped. Check that the fan has not

been blocked. If, after checks and/or resetting of the motor

protection, the fan does not start, contact the manufacturer.

Repair or replacement of components is not permitted on

ATEX approved fans. For other questions regarding the fan

function, contact Technical support.

After maintenance, service or repair check that:

- the impeller's balance weights have not moved and the impeller

blades have not been distorted. After cleaning, the motor must be

run for 30 mins. at 80-100% of its rated voltage to dry out fully. This

allows any water that has penetrated to evaporate.

- listen for abnormal operating noise and check for vibration free

operation.

Other

- The fans must be cleaned as necessary, however, at least once

annually to prevent imbalance resulting in unnecessary bearing

damage. Bearings should be tested for discordant noise, motors

have maintenance free bearings with (special grease). A bearing

change is required at any sign of wear, or after 40,000 hours at the

latest. Contact Technical Support!

- A filter will prolong the time interval between each cleaning of the

fan.

13

- Capacitor Ex140/180 has a piece of sticky tape that covers the

ventilation openings. If the tape is broken the capacitor must be

replaced. Contact technical support.

- For other damage (for example cable grommets) contact

Technical Support.

- If screws must be replaced the strength classification of the new

screws must be at least 8.8 and have suitable screw locks.

Required tightening torques M6 = 9.5 Nm, M8 = 23 Nm, M10 = 46

Nm.

- If fans are stored or started after long periods of disuse or if they

have been exposed to dew for a long period, the insulation

resistance of the motor winding must be tested before the fan is

commissioned. If the values are equal to/less than 1.5 Mohm the

engine winding must be dried.

- The fan largely consists of recycled material, which can be

recycled again when the service life of the product has ended.

Check and follow the relevant legislation for recycling.

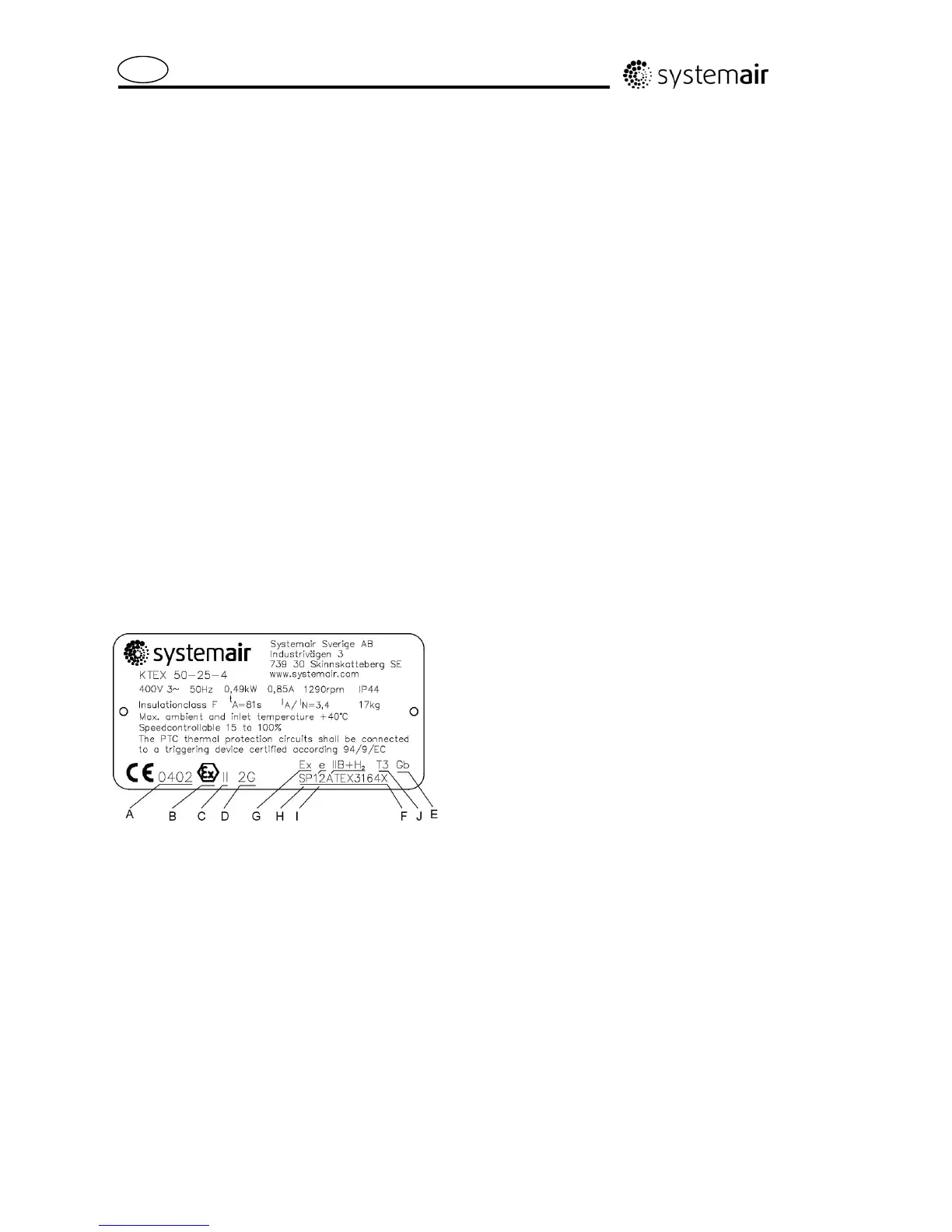

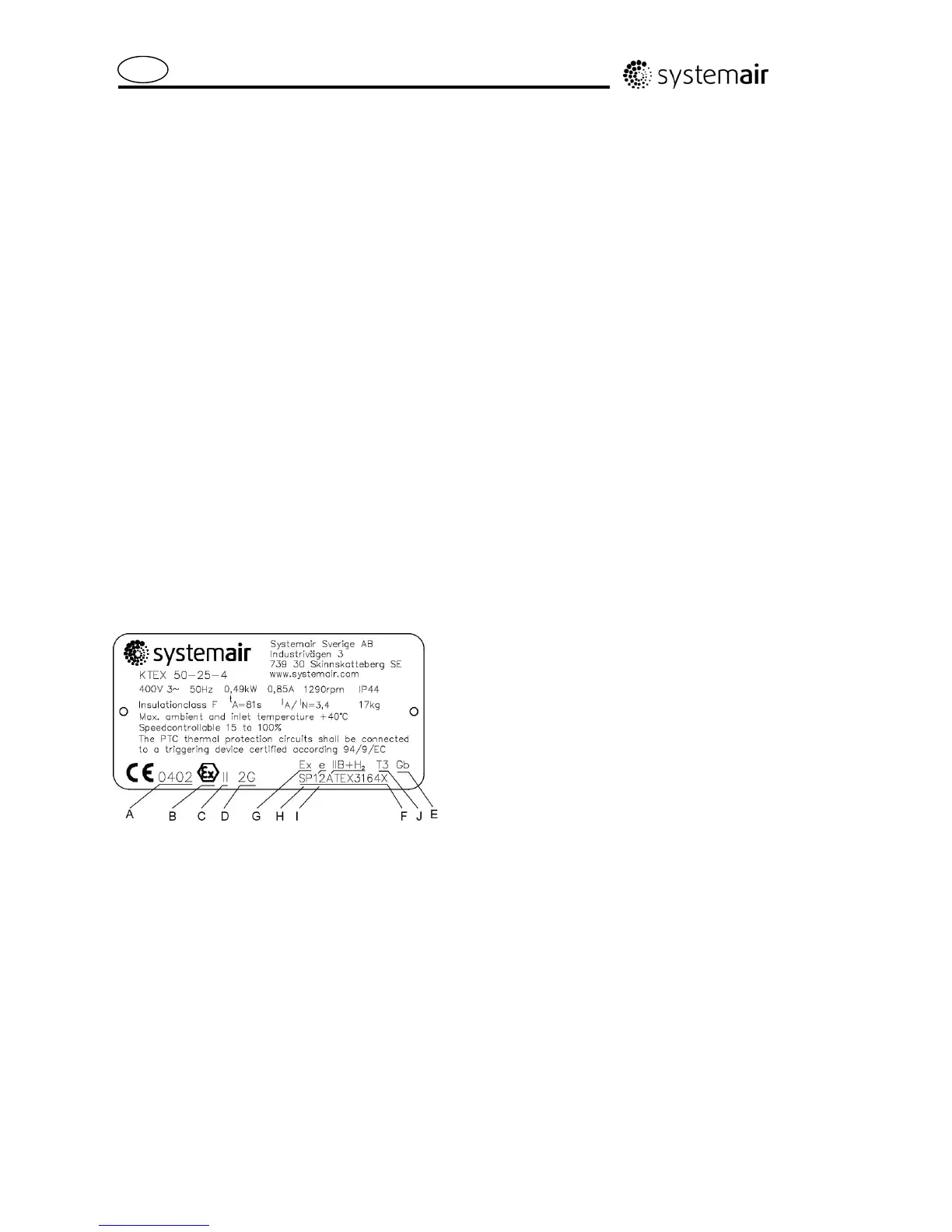

A Notified body number for SP

B The Epsilon-X mark indicates that the equipment comes under

ATEX

C Equipment group II is intended for use in areas with explosive gas,

except mining gas

D Category 2, zone 1, G = potentially explosive gas mixture

can be occasionally expected during normal usage

E EPL Equipment Protection Level

F Certificate number

G Explosion protected material

H Type of protection e = increased protection against sparks

q = protection through sand filling

I Apparatus group IIB (also applies to IIA)+H

2

also applies to

hydrogen

J Temperature class T3, max. surface temperature for fan is 200 °C,

can be used for gas mixtures with ignition temperatures exceeding

200°

Loading...

Loading...