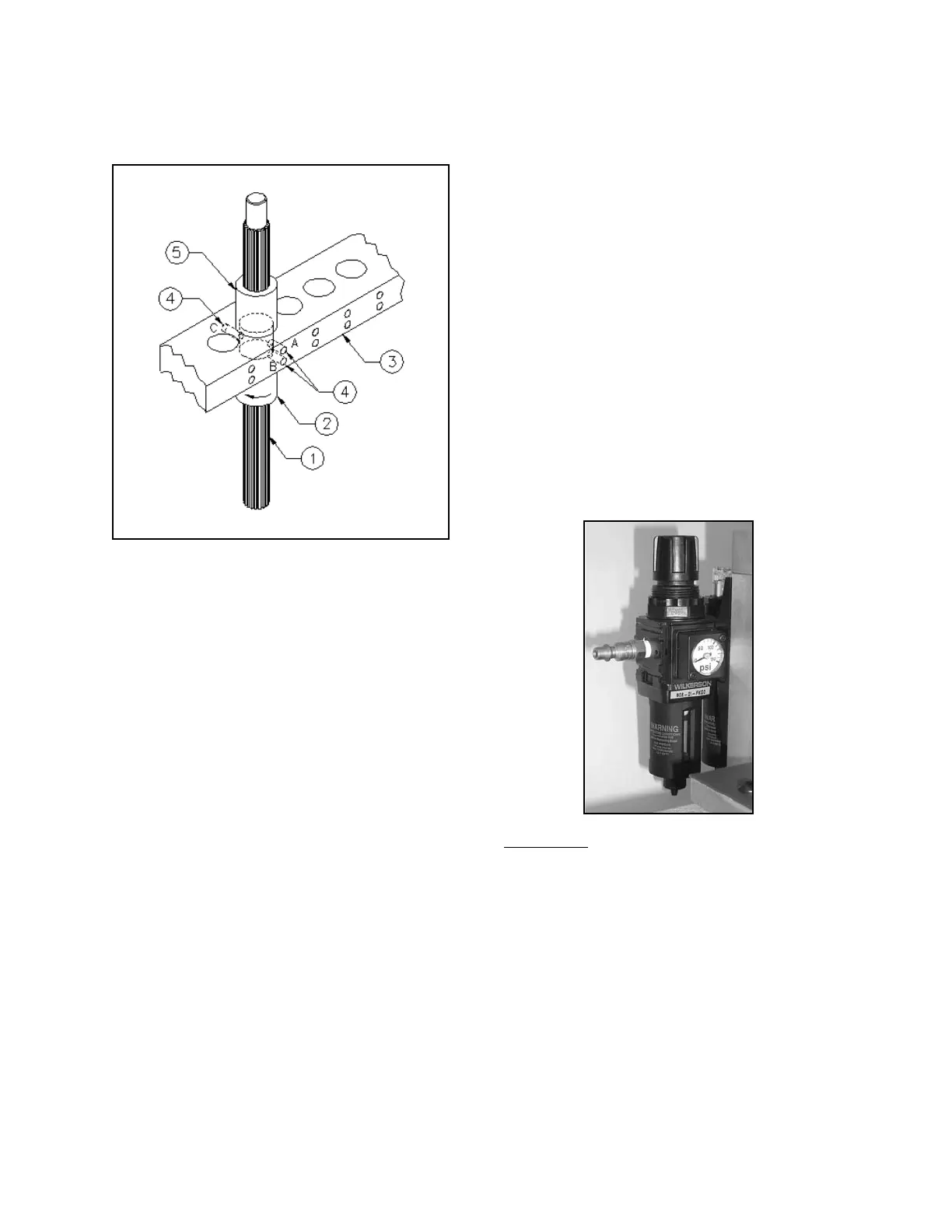

Spline Shaft Finger - Adjustment

The following procedure describes the correct

way to adjust the spline-shaft fingers.

1. Using hex wrench supplied, loosen set screw

and remove weight from spline-shaft finger.

2. If upper bearing (#5) is assembled tightly in

gantry and locked with bottom set screw (#4),

continue with step 3. Otherwise,

a. Remove spline shaft (#1) from bearing

assembly.

b. Hand-tighten upper bearing (#5) and

lock with bottom set screw (#4A).

c. Adjust lower bearing (#2) into beam until

shoulder of bearing is in contact with gantry.

d. Slide spline shaft (#1) into upper bearing

until shaft stops against lower bearing.

Lightly twist lower bearing clockwise until

spline grooves align into lower bearing

and slide freely.

3. Loosen two adjustment set screws (#4B & C)

approximately ½ to ¾ turn.

4. Apply light tension between spline shaft and

lower bearing by slightly twisting lower bear-

ing counter-clockwise.

5. Using hex wrench, apply a light tightening force

to top set screw (#4B) locking lower bearing

into place. WARNING, DO NOT OVER

TIGHTEN SET SCREW. Spline shaft will no

longer move freely through bearings.

6. Tighten set screw (#4C) on the opposite side

of the gantry until spline shaft moves freely.

7. Re-attach weight and tighten set screws.

Load on Specimen Surface

To check the loading forces, measure directly

under the scratch (mar) tip, using a spring bal-

ance or equivalent. If necessary, adjust the

weight(s) to meet the required scratch force(s) on

the surface of the sample.

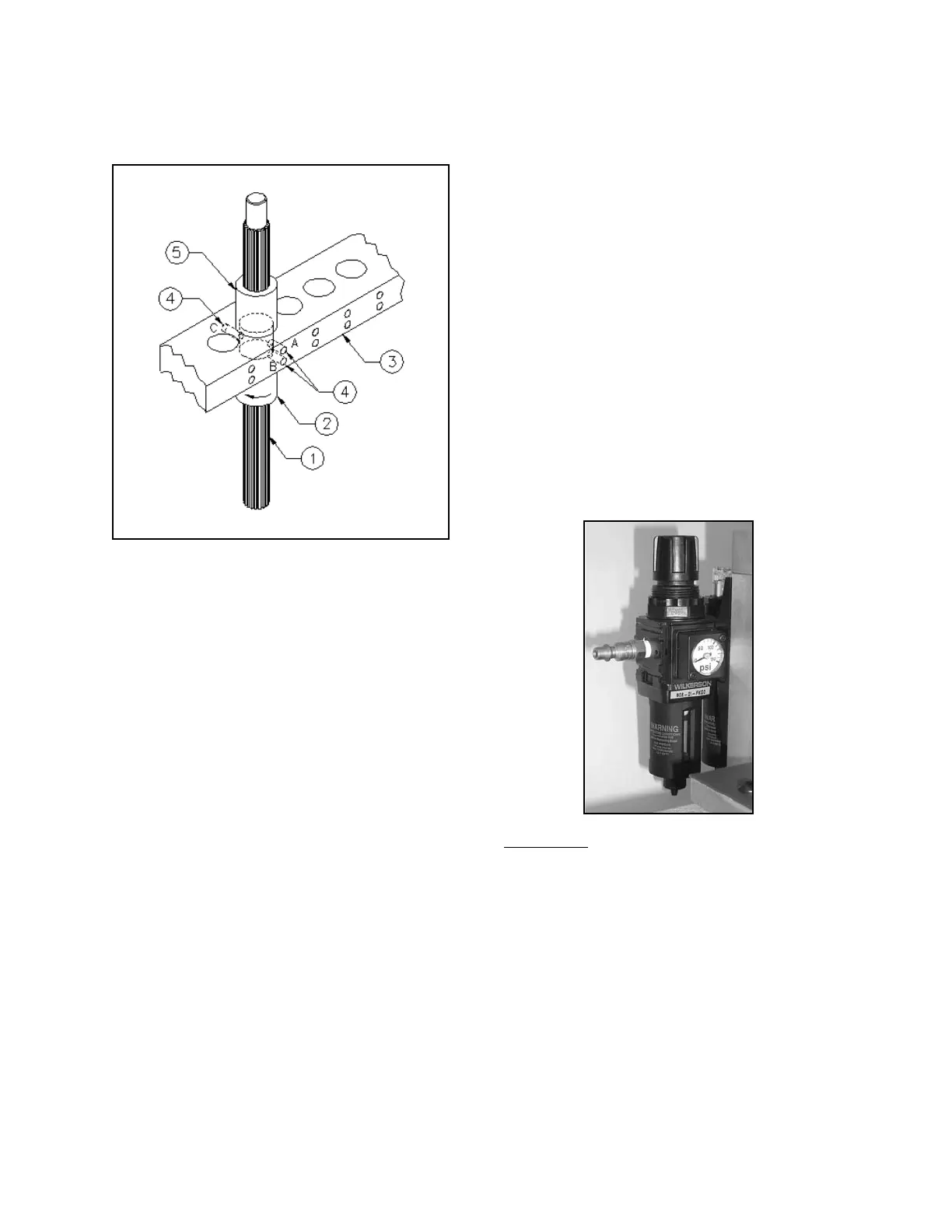

Lubricator / Regulator

The maximum inlet pressures and temperatures

are as follows:

150 psig (10.3 bar)

125° F (51.7° C)

Given normal operating conditions this unit will

be trouble-free. It is recommended that you serv-

ice the unit at least every six months.

CLEANING:

To clean bowl assembly:

a. Depressurize unit.

b. Remove bowl and bowl guard assembly by

turning counterclockwise.

c. Inspect bowl daily for damaged or deteriorat-

ed seals. Replace with original manufacturers

approved seals and bowls.

d. If bowl becomes dirty, replace it or clean it by

wiping the bowl with a soft dry cloth or a mild

detergent.

e. Before returning to service, ensure that all

seals have been reinstalled or replaced.

6 710 Operating Instructions ver 1.1

Loading...

Loading...