16

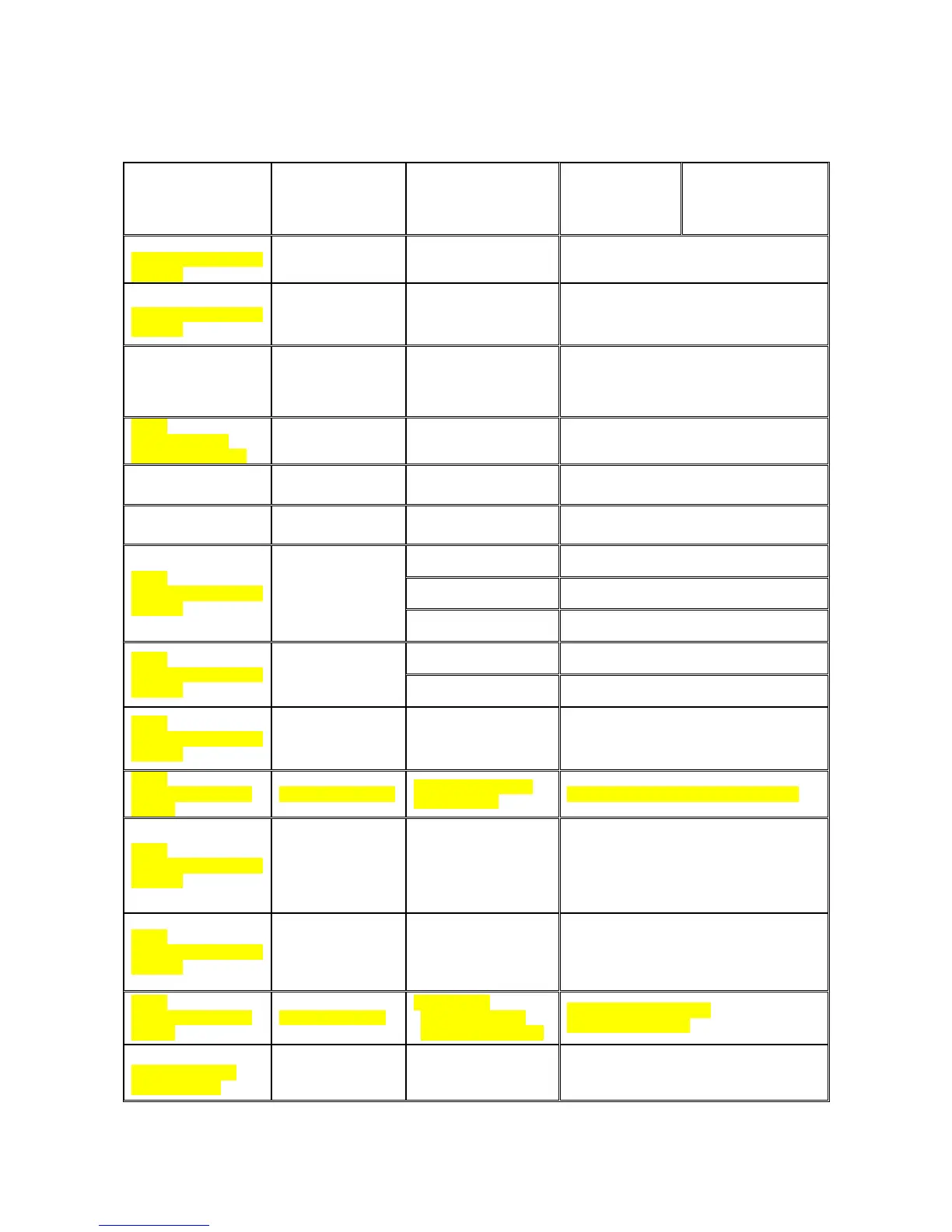

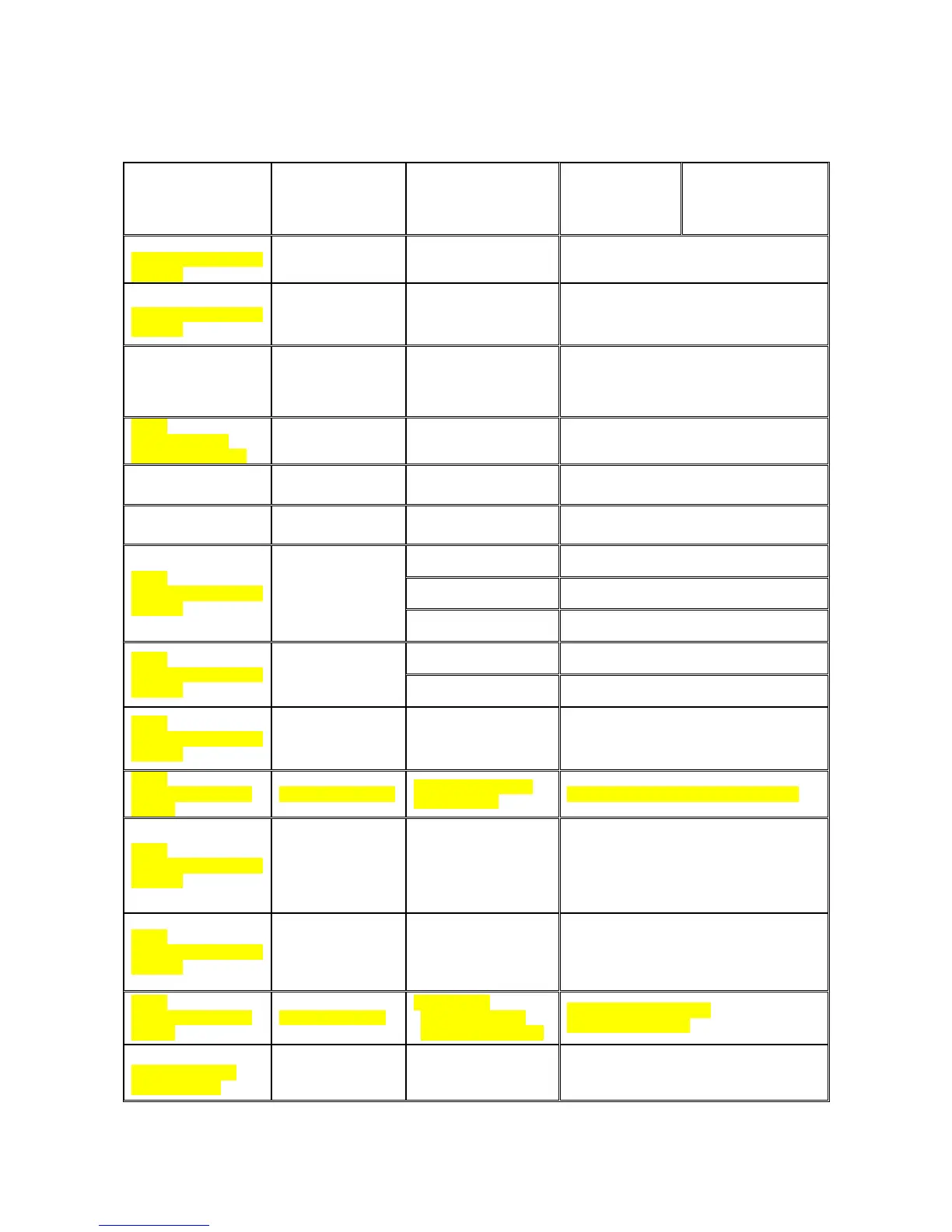

9 – Error codes and what to do:

This table explains the error codes caused by a defective

regulating component or by a security operation.

Screen and state

of the heat pump

Component Possible Intervention

the

intervention is

without effect

PP 01

Compressor and fan

stopped

Water temperature

sensor

non supplied or

defective

Check the connections, the wires,

change it or replace the electronic card

PP 02

Compressor and fan

stopped

exhust

temperature

sensor

Sensor disconnected,

non supplied or

defective

Check the connections, the wires,

change it or replace the electronic card

PP 03

The heat pump

continues running

Defrost sensor

The defrosting is

incomplete and the

automatism decides

to stop the heat pump

Increase lightly the water flow going into

the heat pump; the effect is to increase

the temperature of the refrigerant in the

evaporator.

PP 05

The heat pump

continues running

non supplied or

defective

Check the connections, the wires,

change it or replace the electronic card

PP 07

First anti-frost

protection active

Low temperatures for

water and air

No action required

PP 07

Second anti-frost

protection active

Low temperatures for

water and air

No action required

EE 01

Compressor and fan

stopped

High pressure,

Low pressure

protection

flow

Check the water flow

of order

Replace the pressure switch Have

the heat pump checked by a

refrigeration technician

EE 02

Compressor and fan

stopped

Have the heat pump checked by a

refrigeration technician

EE 03

Compressor and fan

stopped

Flow switch

Flow switch

disconnected, non

supplied or defective

Check the connections, the wires,

change it or replace the electronic card

EE 04

The unit cannot be

started

Emergency switch

Emergency switch

disconnected

Check the connections and the wires

EE 05

Compressor and fan

stopped

Low ambient

temperature

protection

Ambient temperature

is too low or

protection

temperature setting

set too low

Check and repair.

EE 06

Compressor and fan

stopped

compressor

exhaust

temperature

sensor

temperature

detected up to 95°C

more than 3 times in

1HR

Environment problem

Refrigerant leakage

Capillary is half blocked

EE 07

The unit cannot be

started

Phase protection

Connection

disconnected or

wrong phase wiring

Check the connections

Put phases in order

EE 08

The wire control

can't operated

Wire control

Communication

error

Signal cable of wire

Control is loose

Check the connection of signal cable

20

Loading...

Loading...