3

Adjusting the Saddle Height

To adjust the saddle and seat posi-

tion correctly and safely, please refer

to the information in the original op-

erating instructions which can be found in the

chapter “Adjusting the bicycle to the rider”.

The seat post has been folded for transport.

Open the quick release or loosen the Allen key

on the seat post clamp and pull the seat post

into the suitable position.

Please note that the saddles of Pedelecs that

are equipped with a hydraulic or spring-operated

seat post may sink a little after you have mounted

them. This changes the seat position.

Once you have found a suitable seat position,

close the quick release again or tighten the

screw of the seat post clamp again.

The seat post has a minimum lowering depth that

can be found at the bottom end of the seat post. If

it is exceeded, there is risk of breakage.

Assembly

After assembly and adjustments are

complete, be sure to check that all

screw connections and fas-

teners are securely xed.

The vehicle has had lubricants applied at various

locations. Always wear appropriate clothing and

personal protective equipment, such as suitable

gloves, when assembling.

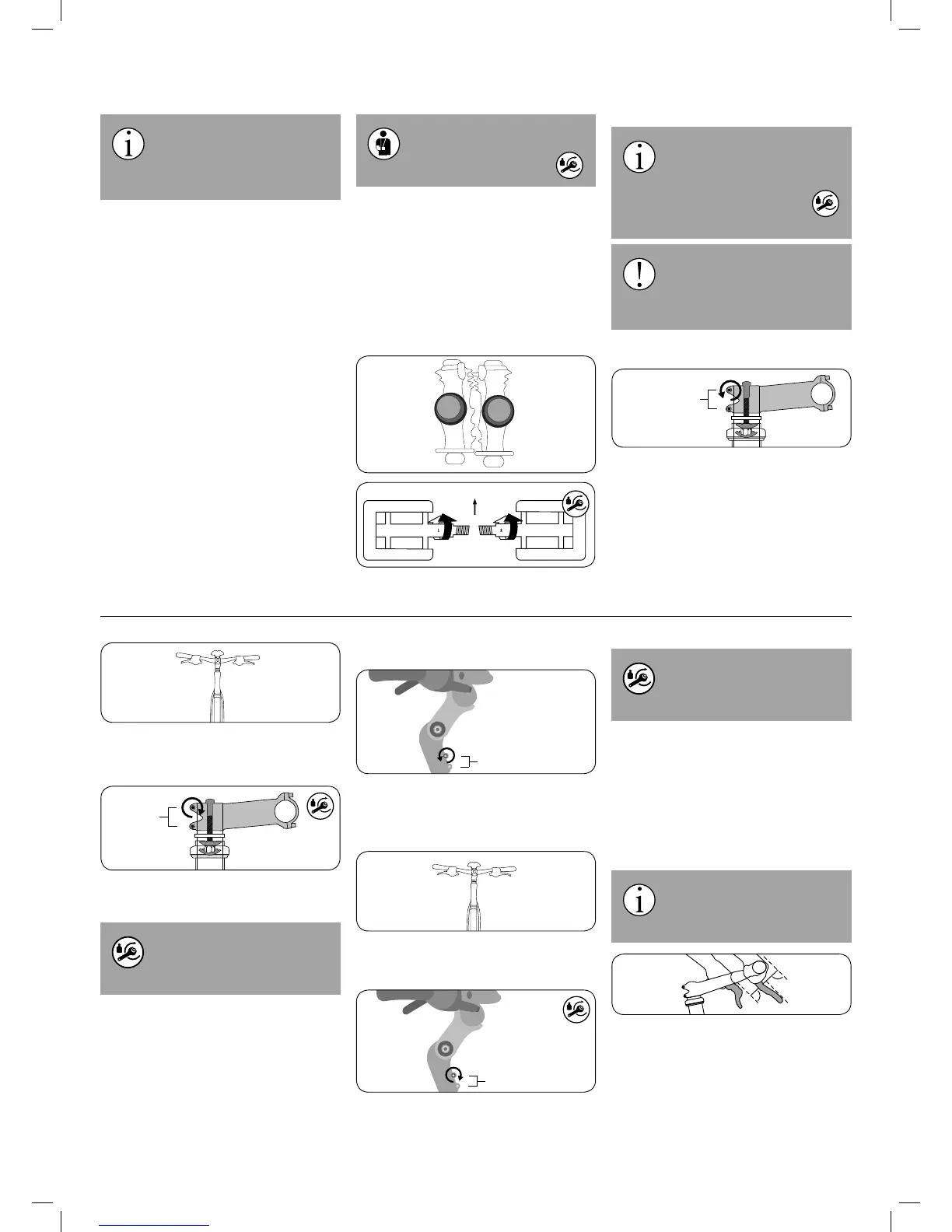

Assembling the Pedals

The pedals are marked “L” for “left” and “R” for

“right”. Turn the right pedal into the crank arm on

the chainring side and the left pedal on the op-

posite side.

Apply assembly grease to both threads before

installing the pedals.

Note that the right pedal must be

turned clockwise, while the left ped-

al must be turned counterclockwise.

To do this, use an open-end wrench, an Al-

len key or a special long pedal

wrench. The appropriate tightening

torque is 40 Nm.

If the pedals are mixed up or cross-

threaded, the threads will be dam-

aged. The pedals could break o

from the crank, which can lead to a crash

and severe injuries.

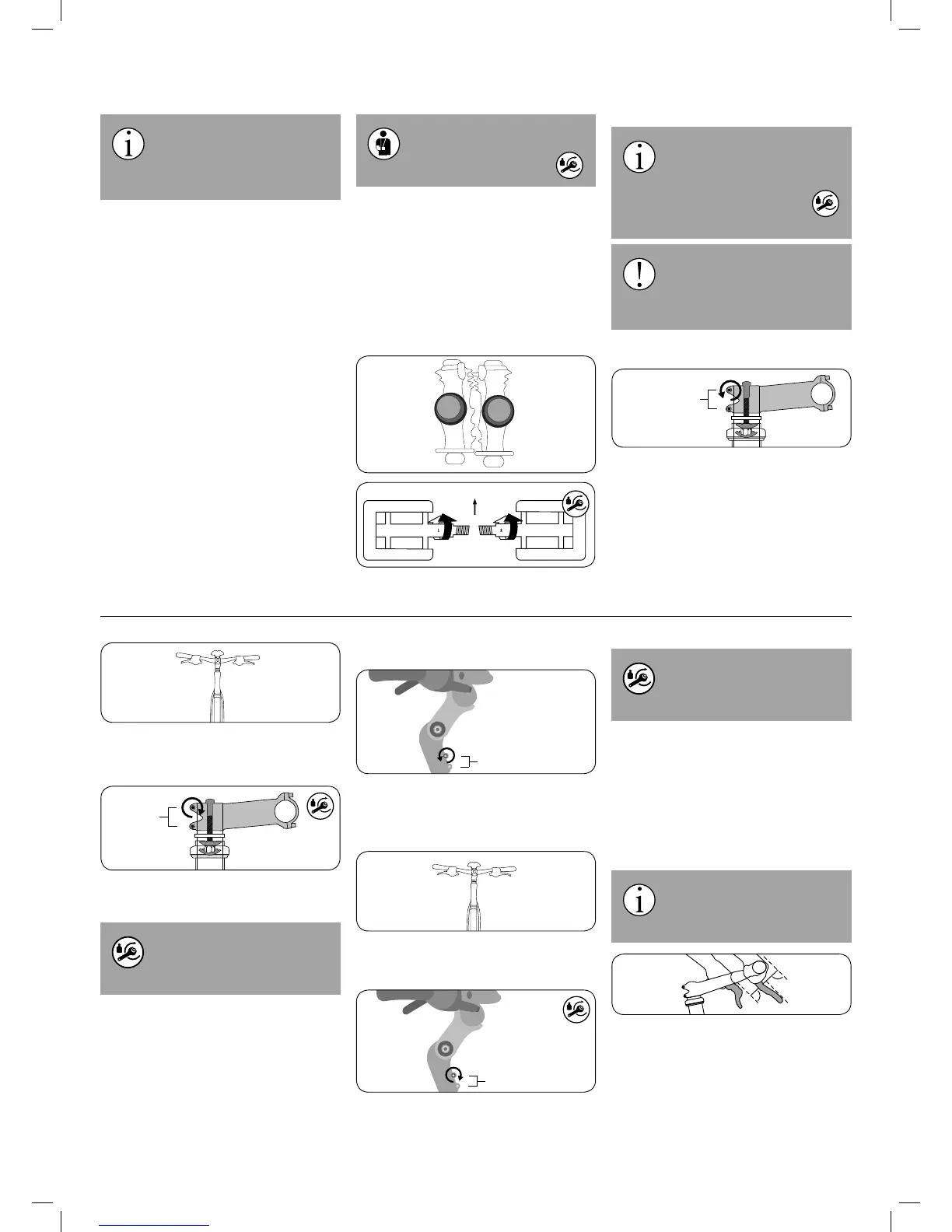

A-Head Stem

1. Loosen the stem clamping screw of the stem

with a 5 mm hex key, turning counter-clock-

wise. Back it out only a few turns.

2. Align the stem so that the handlebars are at

exactly a 90 degree angle, perpendicular to

the front wheel.

3. Now use a torque wrench to tighten the stem

clamping screws clockwise.

An A-head stem must be tightened

to 6 – 8 Nm. If a dierent tightening

torque is marked on the component,

use that torque instead.

Adjustable A-Head Stem

1. Loosen the stem clamping screw on the bot-

tom of the stem with a 5 mm hex key, turn-

ing counter-clockwise. Back it out only a few

turns.

2. Align the stem so that the handlebars are at

exactly a 90 degree angle, perpendicular to

the front wheel.

3. Now use a torque wrench to tighten the stem

clamping screws clockwise.

An A-head stem must be tightened

to 10 – 12 Nm. If a dierent tighten-

ing torque is marked on the compo-

nent, use that torque instead.

Information on adjusting an adjustable stem can

be found in the chapter “Adjusting the bicycle to

the rider” and possibly also in the enclosed in-

structions of the parts manufacturer.

Brake Levers

Set up your brake levers in such a way that you

can safely apply them and brake comfortably.

The brake levers should be set up

so that your hands can apply them

as a straight extension of your

arms.

Loading...

Loading...