FORM 119-ING. 04/11

We reserve to modify our production without previous communication

.

6/8

3.3 VALVE WITH OPEN LEVER

3.3.1 - Type “B”

For assembling carry out the same operations of point 2.3.1) but in reverse order, tightening first of all the nozzle (1)

into the valve body (7). Before pushing the spring (13), make sure that the blowdown ring (5) is free and does not

touch the disc holder (3).

Once assembled the valve and tightened the lock nut (16) it is necessary to put the disc (33) and the lock nut (27) at

the end of the thread and tightening one against the other.

After assembling make sure that the lever can turn easily with no efforts and without interferences

3.3.2 - Type “D”

For assembling carry out the same operations of point 2.3.2) but in reverse order, tightening first of all the nozzle (1)

into the valve body (7). Before pushing the spring (13), make sure that the blowdown ring (5) is free and does not

touch the disc holder (3).

Once assembled the valve and tightened the lock nut (16) it is necessary to put the disc (33) and the lock nut (27) at

the end of the thread and tightening one against the other.

After assembling make sure that the lever can turn easily with no efforts and without interferences

4. MAINTENANCE

The safety valves requires an ordinary but careful maintenance ( SEE MAINTENANCE PLAN ) and in case it should

be necessary , follow the operation stated in point 2) for disassembling and in point 3) for assembling.

In case of seat damaging it is necessary to carry out a new lapping: this operation has to be executed by skilled

workers.

In case of inconveniences should occur to the valve, verify if in DAMAGE TABLE are contained some useful

instructions for solving the problem.

If the damage is different from what stated in the table, contact our Service Department.

WARNING

The safety valves should not be subjected to bumps or such stresses that could compromise the

working.

High loads on the spring can damage the valve.

The safety valves must be used only exclusively for the use stated in the construction declaration.

The safety valve must be revised within two years from installation for dangerous fluid (Group 1) and

within three years for other fluids (Group 2) independently from the number of interventions executed by

the valve.

ACCESSORIES

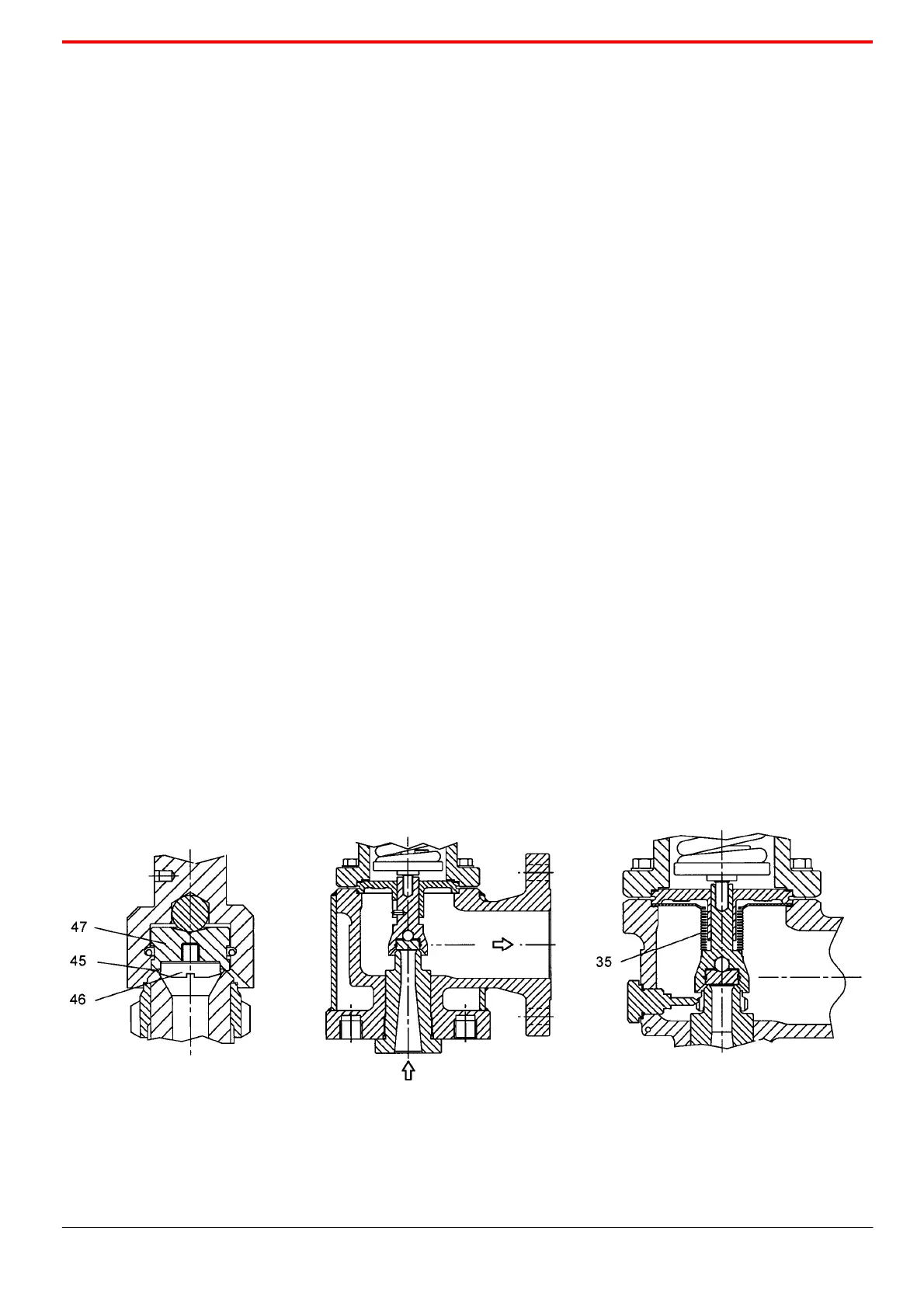

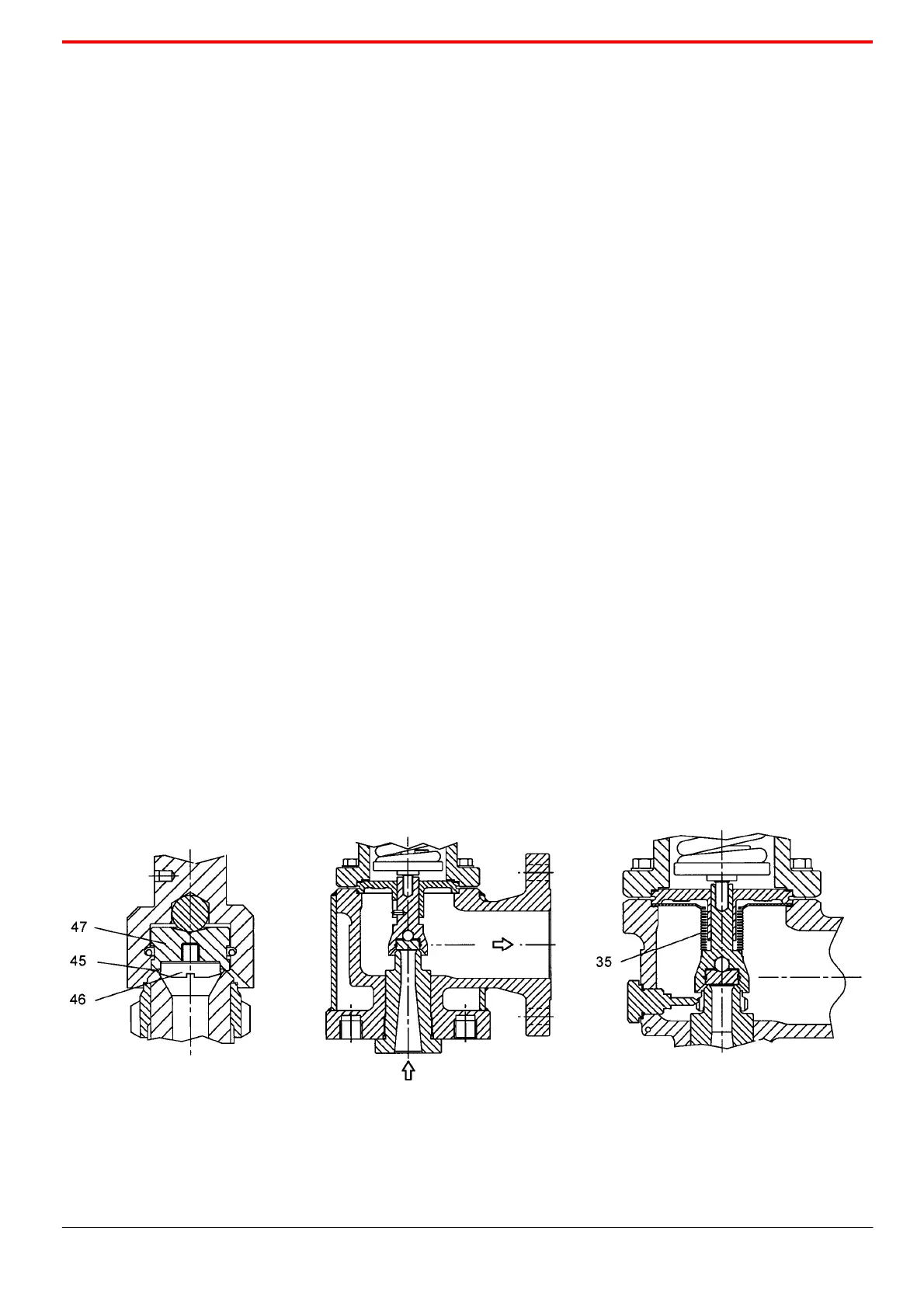

SOFT SEAT JACKET BELLOWS

Loading...

Loading...