FORM 119-ING. 04/11

We reserve to modify our production without previous communication

.

7/8

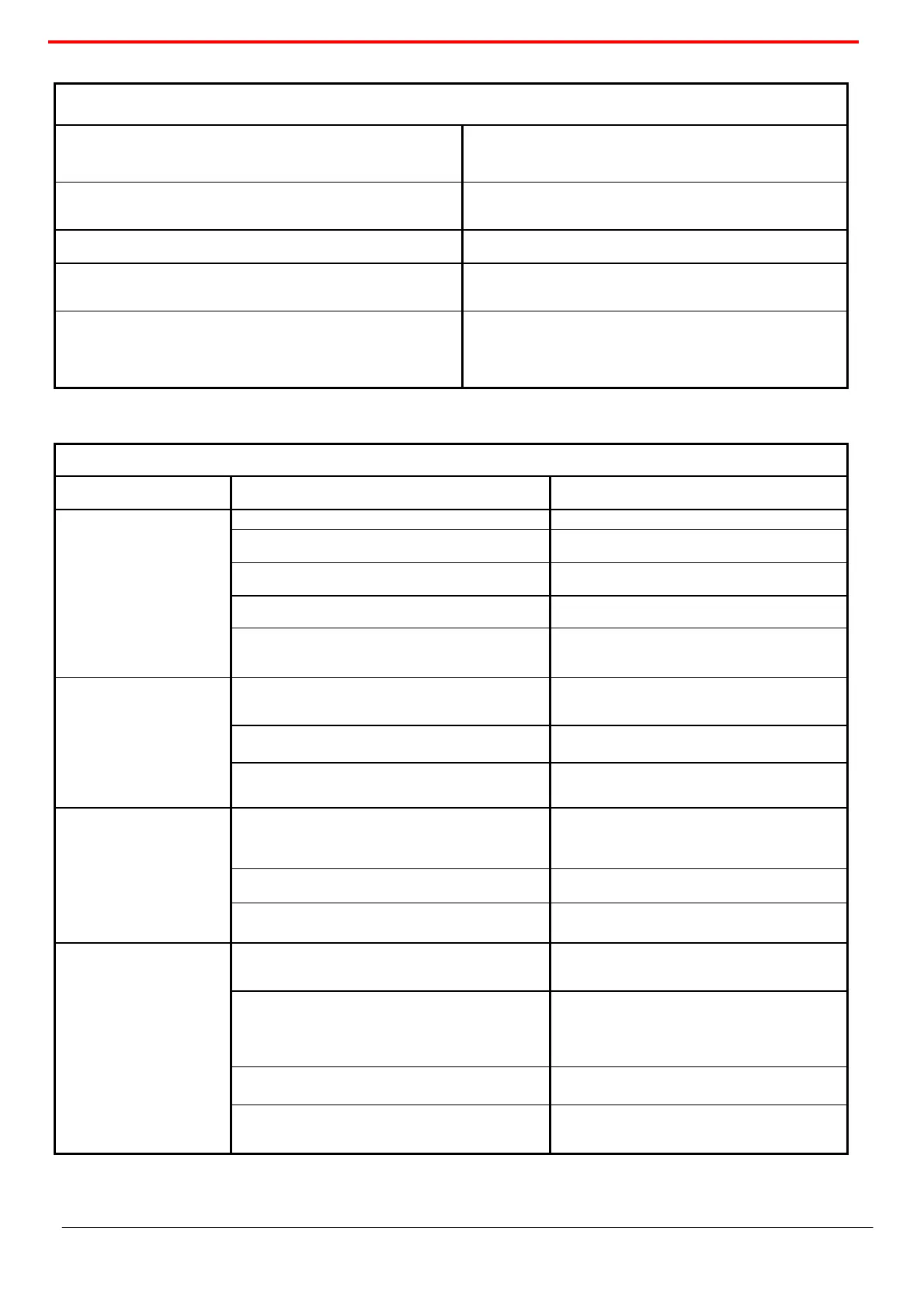

ORDINARY MAINTENANCE PLAN

Check of seat and disc tightness on the plant

Every valve opening

or

every 6-month working.

Check of outwards valve tightness in case of back pressure on the

plant.

Every 30 days.

Check of the painting condition on the plant.

Every 6 months.

Ordinary maintenance of the valve installed on the plant, including the

tightness check and the surface check of the movable components.

Every 12-month working.

General maintenance of the valve removed from the plant including the

disassembling, the seat and the disc check, the incidental seat and

disc lapping, gaskets substitution, painting restoration and test on the

test bench.

Every opening with seats damaging

or

every 24-month working (Group 1)

every 36-month working (Group 2)

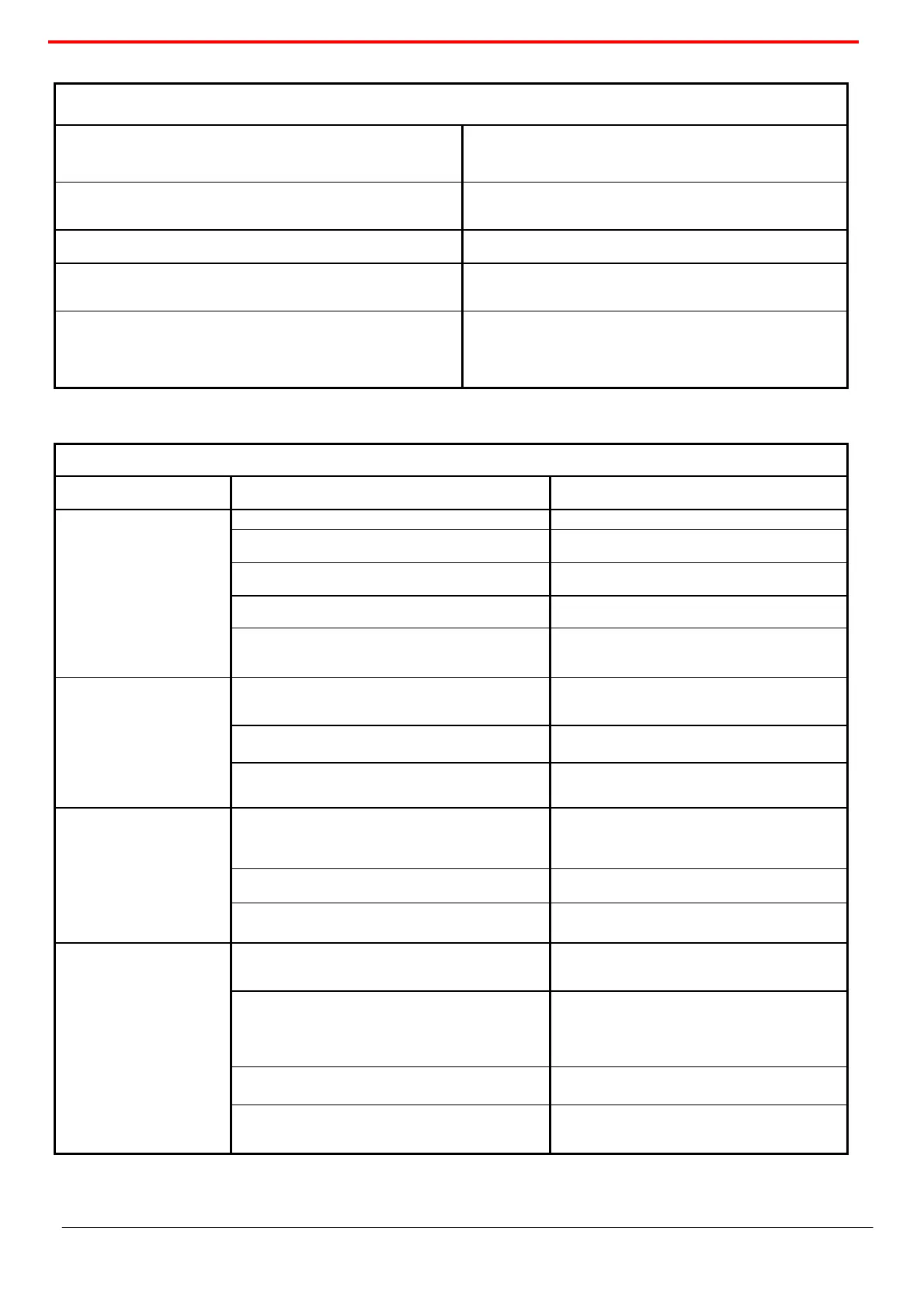

DAMAGE TABLE

INCONVENIENT POSSIBLE DAMAGE ACTION TO BE CARRIED OUT

Fluid leakage in-line Seat wear and tear Nozzle substitution or revision

Disc wear and tear

Disc substitution or revision

Seat and disc damaging

Nozzle and disc revision

Impurities presence between seat and disc

Nozzle and disc cleaning and revision

Valve-use with fluid different from the one stated in the

purchase order

Nozzle and disc revision

Valve gaskets damaging Gaskets substitution

Valve body-bonnet damaging Valve revision or substitution

External back pressure fluid

leakage.

Cap or blowdown screw loosen

Check and setting-up of the cap and of the

blowdown screw.

Opening at pressure value

different form setting valve

Back pressure variable

Check of dimensioning and of the discharge piping

working conditions and possible valve substitution

with another type.

Spring release Spring substitution and check compatibility of the

material with the fluid.

Setting screw withdraw

Resetting the valve and tighten very well the lock

nut

Valve intervention with quick

opening and re-closures

repeated in the time

Strong pressure loss in the inlet piping Check the inlet piping length

Not correct setting-up of the blowdown ring Withdraw the blowdown ring until obtain a proper

working, basing the first regulation one table 1; for

liquid fluids withdraw the blowdown ring

completely.

Pulsating flow rate to be discharged Check plant regulation.

Over dimensioned valve Substitute the valve with one correctly

dimensioned.

Loading...

Loading...