CONTENTS

INTRODUCTION

MSCHEMATIC

DIAGRAMS

SAFETY

PRECAUTION......c.ccccccsccscssesessssesesesseees

1-2

WIRING

CONNECTION

Diagram..........ccccsecees

11-1

TERMINALS

sas

pecs

eatatac

tes

cu

aed

1-3

BLOCK:

Dial

alits

ces

eveintssasvaliczess

We

edechscedeineacetes

11-3

SINITIAE,

SETTING

sas

tcntitiieeteonts

ce

eteteton

dS

MAIN:P2C

Boatds,

cisucnienmastiaascidits,

|

CONTROLS

AND

FUNCTIONS..........ccccsseeseseseees

1-4

MAIN

P.C.

Diagram...

ccc

eeeeeeeeeeees

-9

CONDUCTOR

SETTINGS

..ccccccccccccsssssssescssessseees

1-6

KEYBOARD

RENGES.iececcccsssssssssescesessssssssesesssse

ey

FAJ/LAMP

TBAT

T#/-P.C.Board.....ssssesssseeeeeeee

1-13

PARTS

LOCATION

1-7

POee

eee

eeeeICCCErererrr

rr

er

erer

rrr

ere

reer

rr

ees

FAJ/LAMP1/BATT+/-P.C.

Diagram....................01-15

DISASSEMBLY

INSTRUCTIONG....................0.6

I-8

INSEE

ABOUT

THE

SELF-DIAGNOSTIC

FUNCTION...

I-11

CP/MKB1/MKB2/MKB3/INS(BEND)

SYMPTOMS

WHICH

APPEAR

P.C.Board.........

TI-17

TO

BE

SIGNS

OF

TROUBLE.............:ccese

I-13

TERI

CP

P.C.

Diagram...

ceecceceeseseseessseesees

II-19

ERROR

DISPLAY...........:csscccsssccesscsecseeeestseeesees

145

INS(BEND)

PRECAUTIONS

BEFORE

SERVICING..............

1-16

MKB1/MKB2/MKB3/INS(BEND)

P.C.Diagram...I-21

MIDI

IMPLEMENTATION

CHART.

......ccccscceceeeee-

I-17

Mi

REPLACEMENT

PARTS

LIST

P.C.Board/

WIRING...

ccccccscsescsesscscscsescsecececscses

W-1.

CABINET

PARTS

LOCATION.....c-ccccscsccccsseeeseess

m-5

CABINET/CHASSIS

PARTS

LIST.....cccccccssssesseees

Il-7

PAGING

cc.

eeeedeionll

xx

tdaresieclcsescsaed

I-8

SAFETY

PRECAUTION

@

Safety

Precaution

1.

Before

servicing,

unplug

the

power

cord

to

prevent

an

electric

shock.

2.

When

replacing

parts,

use

only

the

manufacture’s

recommended

components

for

safety.

3.

Check

the

condition

of

the

power

cord.

Replace

if

wear

or

damage

is-evident.

4.

After

servicing,

be

sure

to

restore

the

lead

dress,

insulation

barriers,

insulation

papers,

shields,

etc.

5.

Before

returning

the

serviced

equipment

to

the

customer,

be

sure

to

make

the

following

insulation

resistance

test

to

prevent

the

customer

from

being

exposed

to

a

shock

hazard.

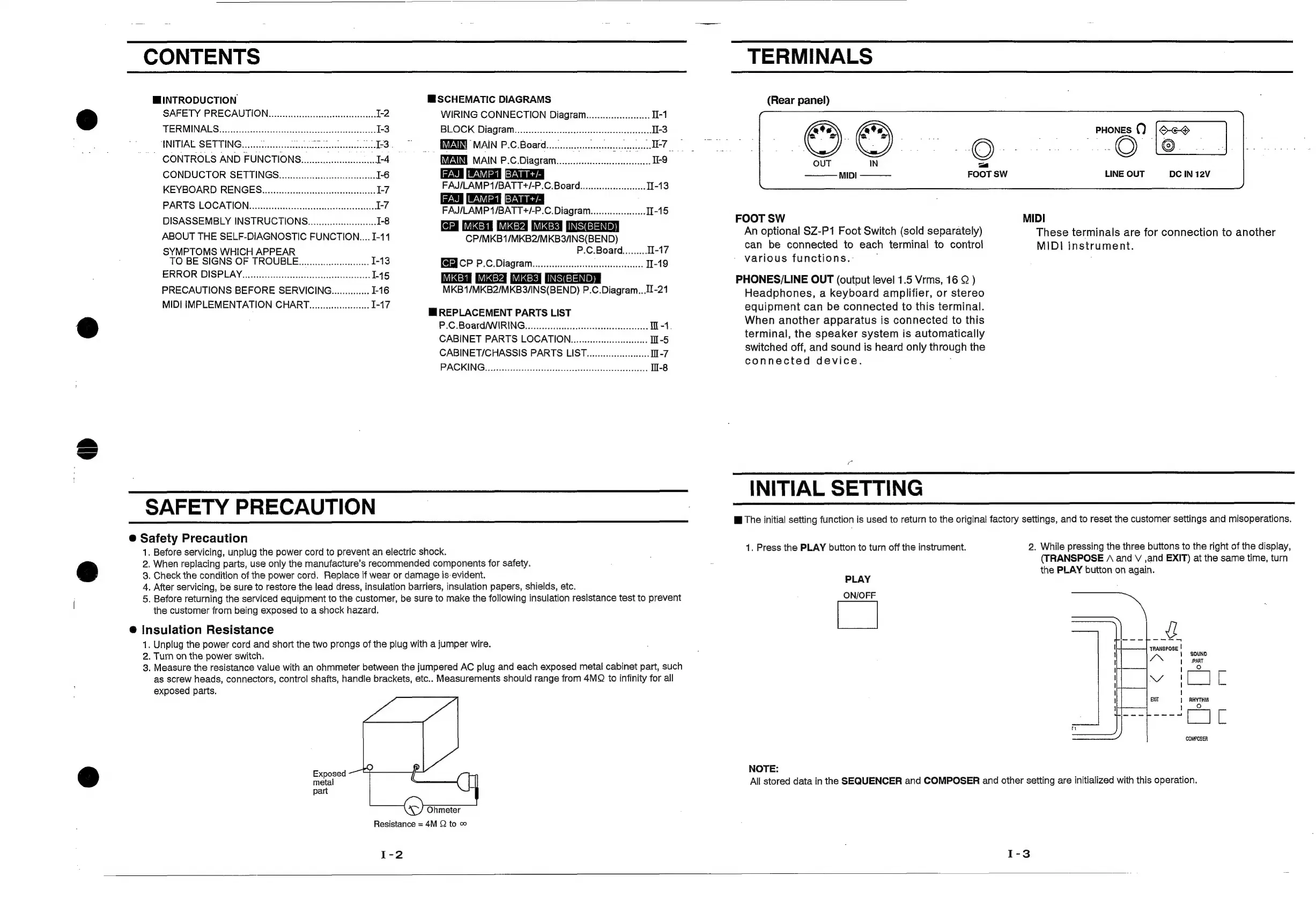

@

Insulation

Resistance

1.

Unplug

the

power

cord

and

short

the

two

prongs

of

the

plug

with

a

jumper

wire.

2.

Turn

on

the

power

switch.

3.

Measure

the

resistance

value

with

an

ohmmeter

between

the

jumpered

AC

plug

and

each

exposed

metal

cabinet

part,

such

as

screw

heads,

connectors,

control

shafts,

handle

brackets,

etc..

Measurements

should

range

from

4MQ

to

infinity

for

ail

exposed

parts.

Exposed

metal

part

Ohmeter

Resistance

=

4M

Q

to

©

I-2

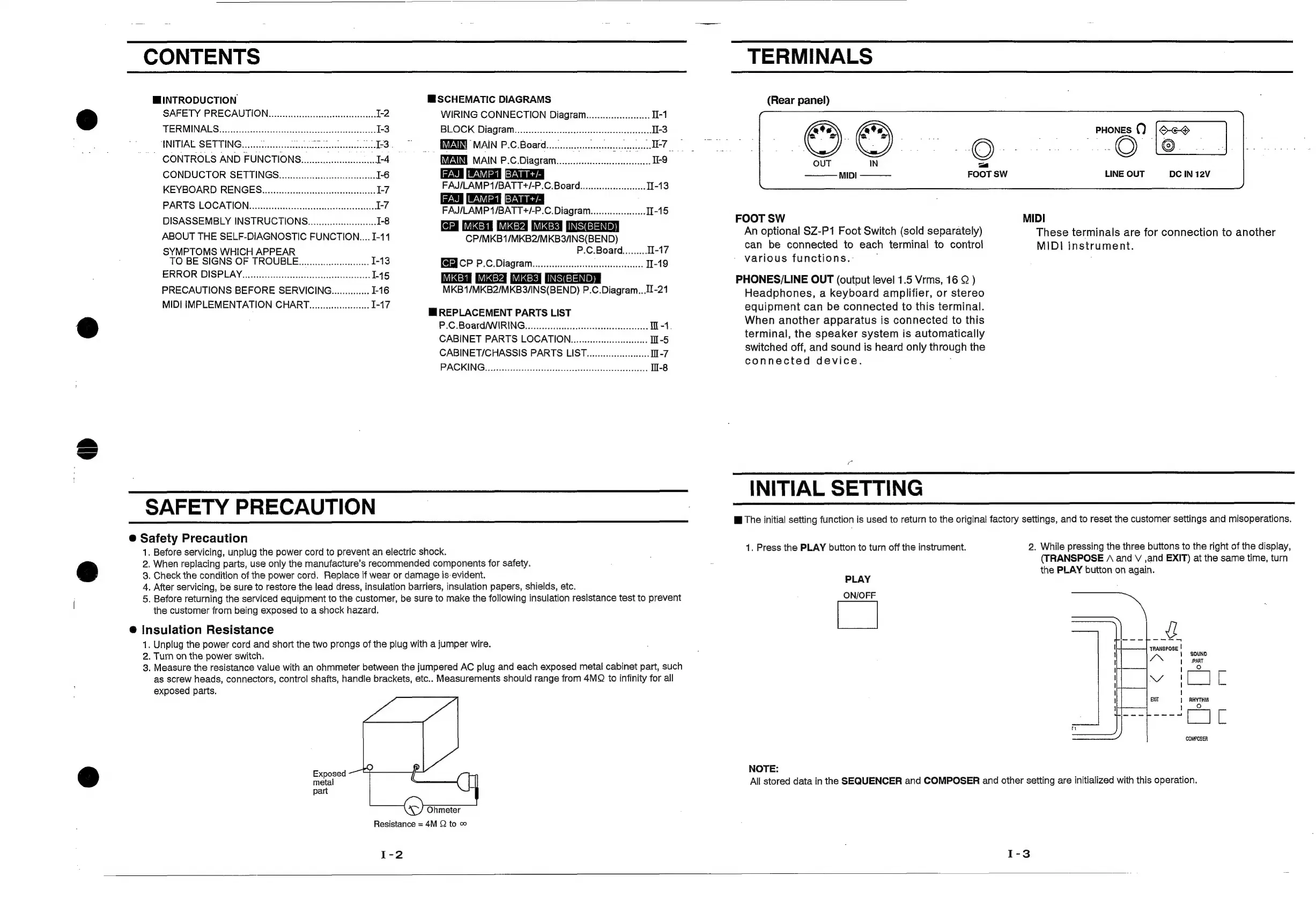

TERMINALS

(Rear

panel)

_

PHonEs

0)

|O-e-@

—

|

Mn.

Bhi

eo

—_

MIDI

FOOT

SW

LINE

OUT

DC

IN

12V

FOOT

SW

MIDI

An

optional

SZ-P1

Foot

Switch

(sold

separately)

These

terminals

are

for

connection

to

another

can

be

connected

to

each

terminal

to

control

MIDI

instrument.

various

functions.-

:

PHONES

/LINE

OUT

(output

level

1.5

Vrms,

16

Q

)

Headphones,

a

keyboard

amplifier,

or

stereo

equipment

can

be

connected

to

this

terminal.

When

another

apparatus

is

connected

to

this

terminal,

the

speaker

system

is

automatically

switched

off,

and

sound

is

heard

only

through

the

connected

device.

;

INITIAL

SETTING

i

The

initial

setting

function

is

used

to

return

to

the

original

factory

settings,

and

to

reset

the

customer

settings

and

misoperations.

1.

Press

the

PLAY

button

to

turn

off

the

instrument.

2.

While

pressing

the

three

buttons

to

the

right

of

the

display,

(TRANSPOSE

(\

and

V

,and

EXIT)

at

the

same

time,

turn

the

PLAY

button

on

again.

PLAY

ON/OFF

U

—--_“S4

TRANSPOSE

|

1

SOUND

PART

Ve

ae

RHYTHM

COMPOSER

NOTE:

All

stored

data

in

the

SEQUENCER

and

COMPOSER

and

other

setting

are

initialized

with

this

operation.

Loading...

Loading...