INSTRUCTIONS FOR THE INSTALLER

Installation (Electrical)

These Instructions are for the authorised installer, as a guide to the installation,

adjustment and maintenance, according to the laws and standards in force. Any of

these operations must always be carried out when the appliance has been disconnected

from the electric system.

Installation (Gas)

This appliance is not provided with a combustion product discharge. It is

recommended that it be installed in accordance with the Australian Standard

AS560l/AC60l and any other local regulations or by laws. The quantity of air which

is necessary for combustion must not be below 2.0 m3/h for each kw of installed

Power.

See table of burner power.

The OPERATION of the appliance including the ignition system must be tested

before leavilig.

PF?;.£t3£)?Ti:8appliancecanbefittedintoaworkingareaasillustratedonthe

corresponding figure.

Apply the seal provided over the whole of the area perimeter.

Gas connection

(Fig. 4) Connect the appliance to the gas cylinder or to the installation according to the

prescribed standards in force, and ensure beforehand, that the appliance matches the

type of gas available. Otherwise, see "Adaptation to various types of gas".

Furthermore, check that the feed pressure falls within the values described on the

table: "User chacteristics".

Rigid/semi rigid metal connection

Carry out the connection with fittings and metal pipes (even flexible pipes) so as to

#i:I.n#tiies:Lesst:[t[t:i;nnnf:spg::Sn°cfatrhr:eapop:£t::a:.cktheperfectsealingoftheentire

connection system, by using a soapy solution.

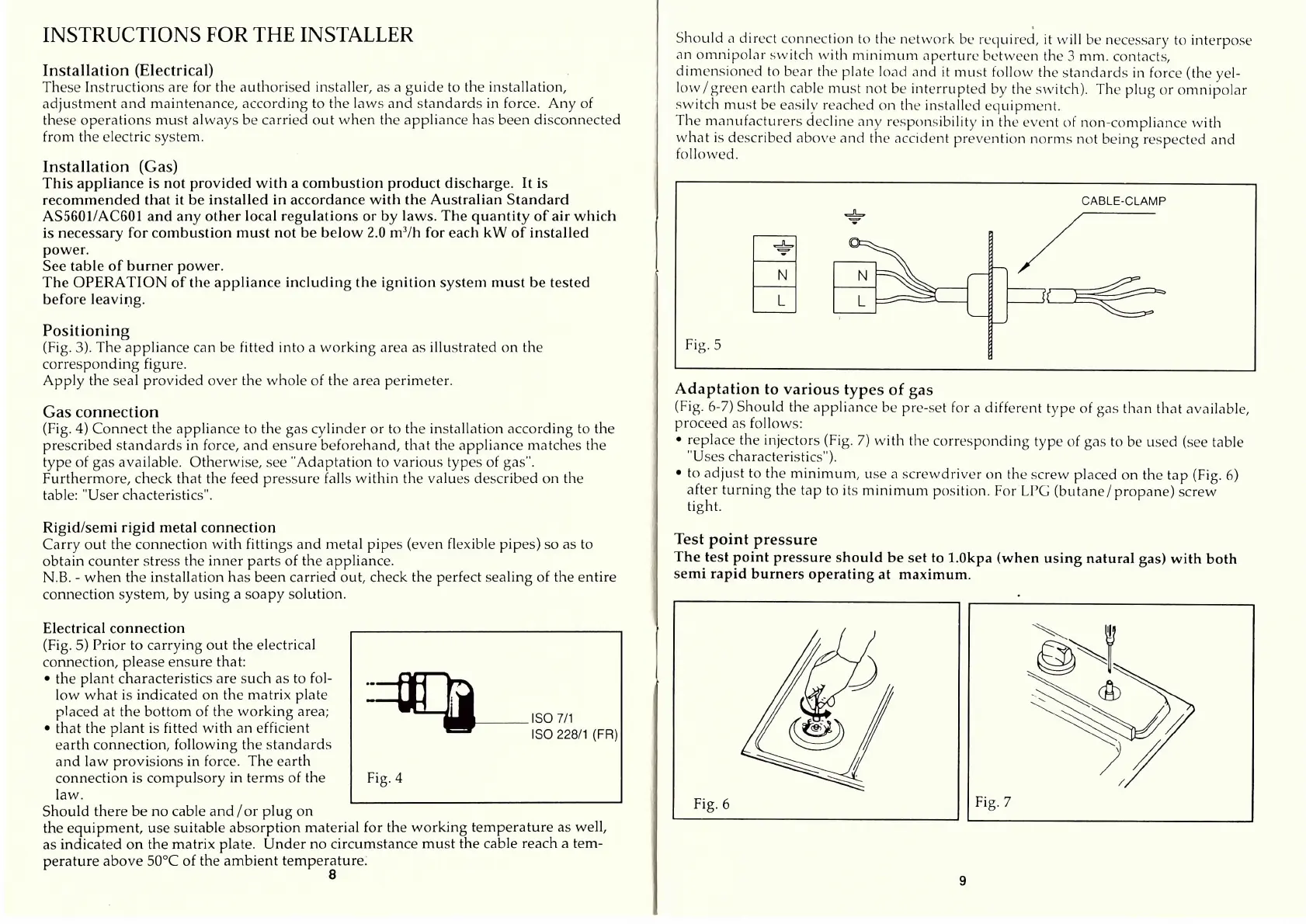

Electrical connection

(Fig. 5) Prior to carrying out the electrical

connection, please ensure that:

•::;Ptahnattc;:::adcftceartj:i£Cosnatrfes:Cahtra;:tp°]:::-

placed at the bottom of the working area;

• that the plant is fitted with an efficient

earth connection, following the standards

and law provisions in force. The earth

connection is compulsory in terms of the

law.

•ffi:S8:£t8,,tFR,

Fig. 4

Should there be no cable and /or plug on

the equipment, use suitable absorption material for the working temperature as well,

as indicated on the matrix plate. Under no circumstance must the cable reach a tem-

peratureabove50°Coftheambienttemper3ture.

Should a direct connection to the network be reqiiired, it will be necessary to interpose

an omnipolcir switch with minimum ciperture between the 3 mm. contacts,

dimensioned to becir the plate locid cilid it must follow the standards in force (the yel-

low/green earth cable must not be interrupted by the switch). The plug or omnipolar

switch must be easily reached on the instcilled equipment.

Tlie maniifacturers decline ciny responsibility in the event of non-compliance witli

what is described above and the ciccident prevention norms not being respected and

followed.

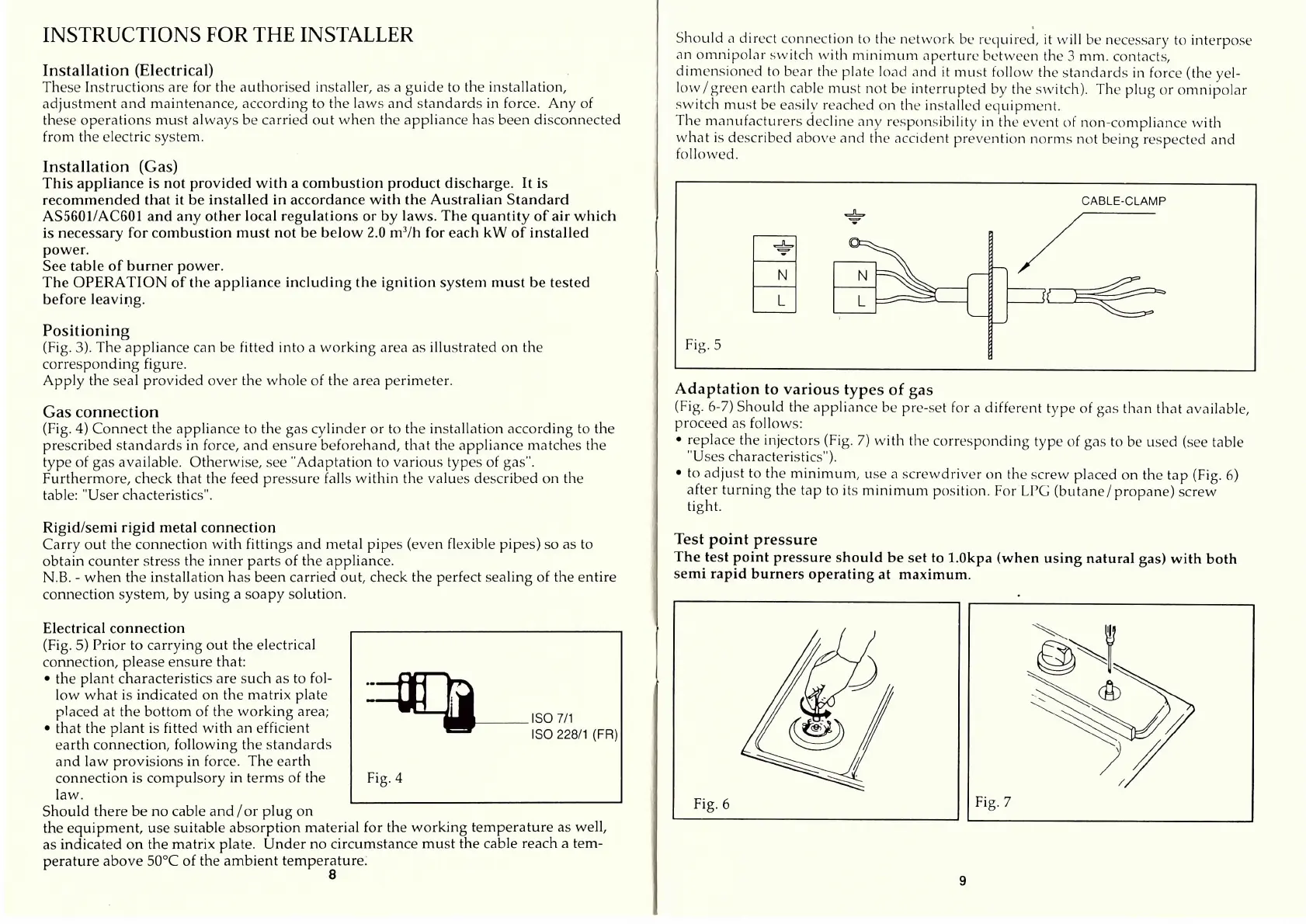

Adaptation to various types of gas

(Fig. 6-7) Should the applicince be pre-set for a different type of gas than thcit available,

proceed as follows:

• replace the injectors (Fig. 7) with tlie corresponding type of gcis to be used (see table

"Uses characteristics").

• to adjust to the minimiim, use a screwdriver ()n the screw placed on the tap (Fig. 6)

after turning the tap to its minimum position. For LPG (butane/propane) screw

tight.

Test point pressure

The test point pressure should be set to 1.Okpa (when using natural gas) with both

semi rapid burners operating at maximum.

Loading...

Loading...