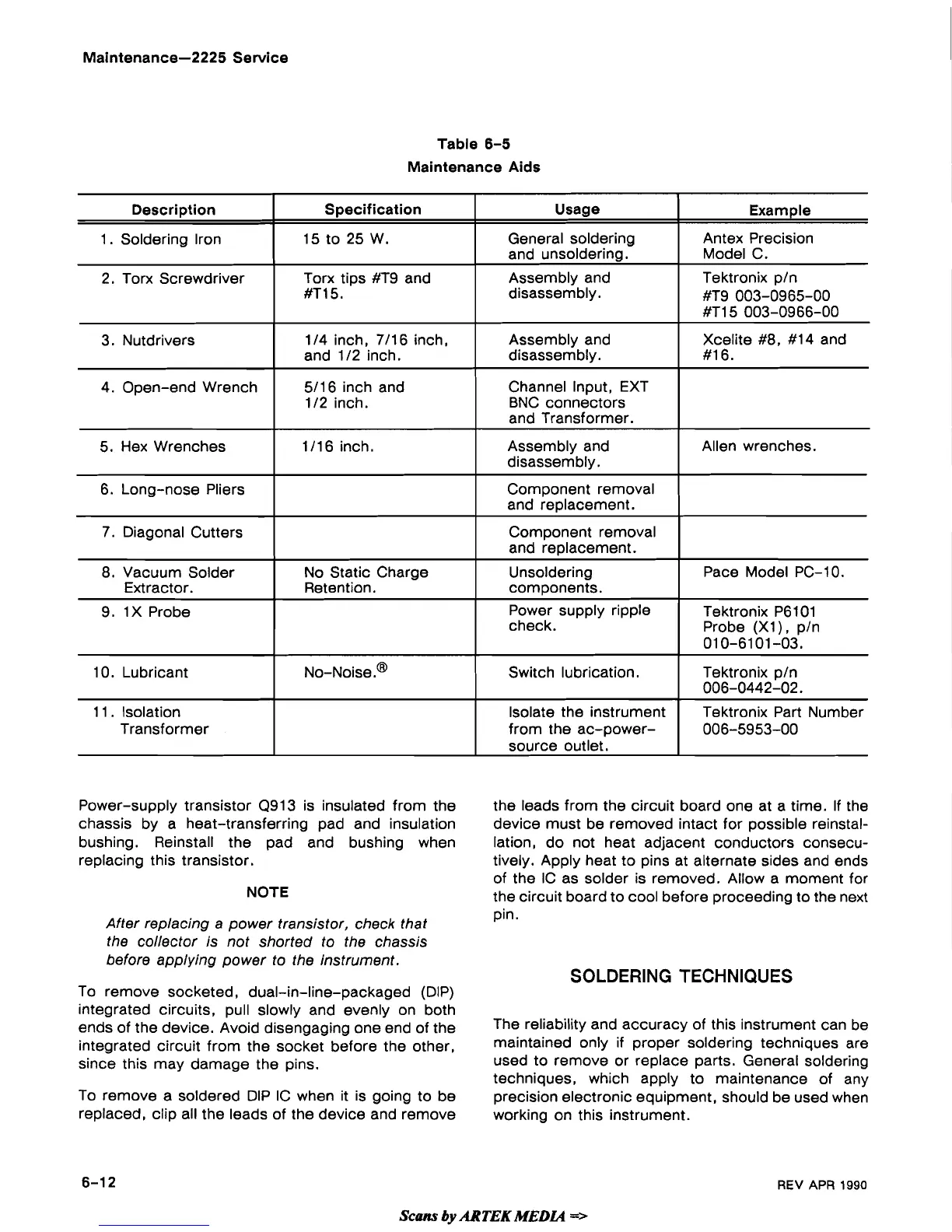

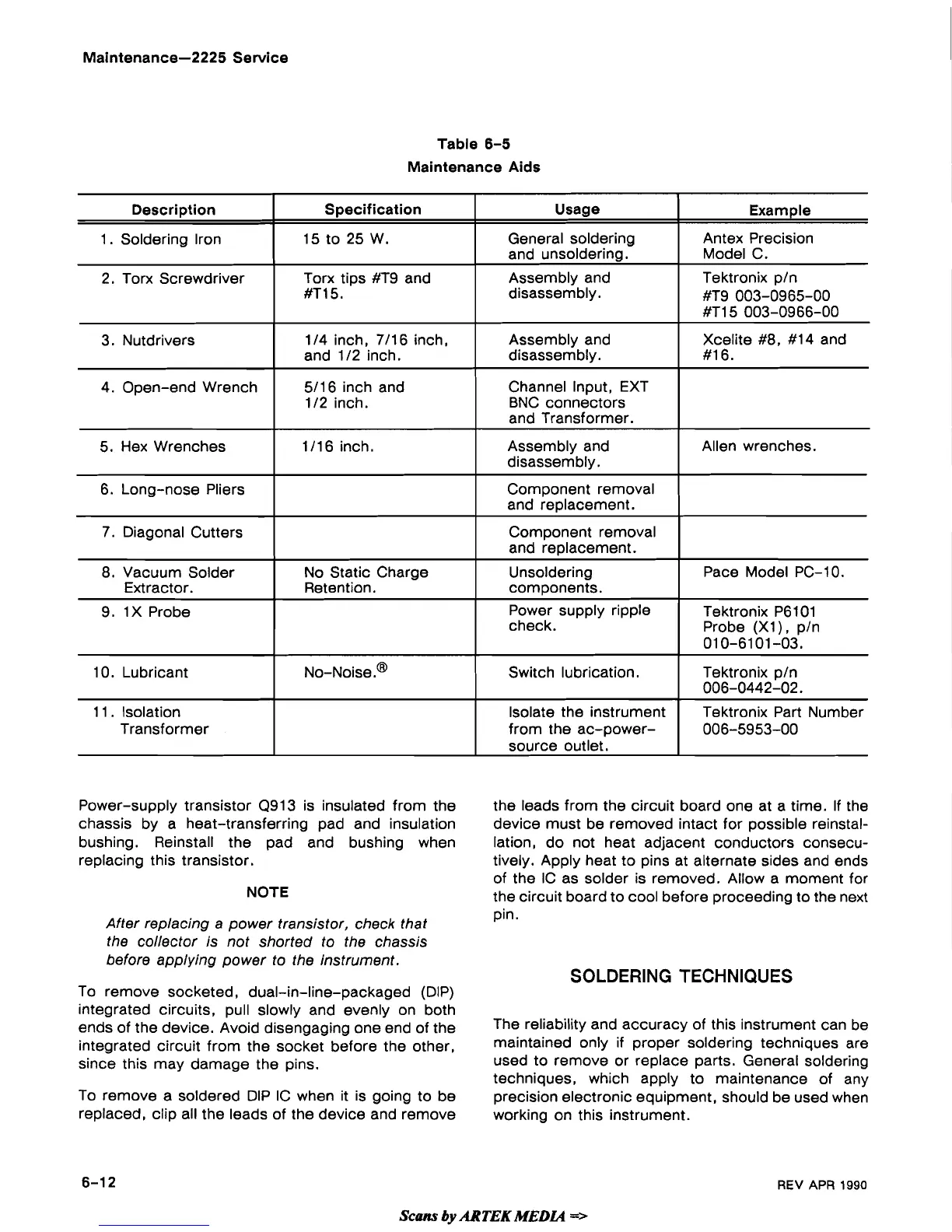

Maintenance-2225 Service

Table

6-5

Maintenance Aids

Power-supply transistor Q913 is insulated from the

chassis by a heat-transferring pad and insulation

bushing. Reinstall the pad and bushing when

replacing this transistor.

NOTE

Example

Antex Precision

Model C.

Tektronix

p/n

#T9 003-0965-00

#TI5 003-0966-00

Xcelite #8, #14 and

#16.

Allen wrenches.

Pace Model PC-1 0.

Tektronix

P6101

Probe (XI

)

,

p/n

01 0-61 01 -03.

Tektronix

p/n

006-0442-02.

Tektronix Part Number

006-5953-00

Description

1. Soldering

Iron

2. Torx Screwdriver

3.

Nutdrivers

4. Open-end Wrench

5. Hex Wrenches

6. Long-nose Pliers

7. Diagonal Cutters

8. Vacuum Solder

Extractor.

9.

1X Probe

10. Lubricant

11

.

Isolation

Transformer

After replacing a power transistor, check that

the collector is not shorted to the chassis

before applying power to the instrument.

To remove socketed, dual-in-line-packaged (DIP)

integrated circuits, pull slowly and evenly on both

ends of the device. Avoid disengaging one end of the

integrated circuit from the socket before the other,

since this may damage the pins.

Specification

15 to 25 W.

Torx tips

#T9 and

#TI

5.

114 inch, 7/16 inch,

and

112 inch.

5/16 inch and

112 inch.

1/16 inch.

No Static Charge

Retention.

NO-~oise.@

To remove a soldered DIP IC when it is going to be

replaced, clip all the leads of the device and remove

Usage

General soldering

and unsoldering

.

Assembly and

disassembly.

Assembly and

disassembly.

Channel Input, EXT

BNC connectors

and Transformer.

Assembly and

disassembly.

Component removal

and replacement.

Component removal

and replacement.

Unsoldering

components.

Power supply ripple

check.

Switch lubrication.

Isolate the instrument

from the

ac-power-

source outlet.

the leads from the circuit board one at a time. If the

device must be removed intact for possible reinstal-

lation,

do not heat adjacent conductors consecu-

tively. Apply heat to pins at alternate sides and ends

of the

IC as solder is removed. Allow a moment for

the circuit board to cool before proceeding to the next

pin.

SOLDERING TECHNIQUES

The reliability and accuracy of this instrument can be

maintained only

if

proper soldering techniques are

used to remove or replace parts. General soldering

techniques, which apply to maintenance of any

precision electronic equipment, should be used when

working on this instrument.

Scans

by

ARTEK

MEW

=>

REV

APR

1990

Loading...

Loading...