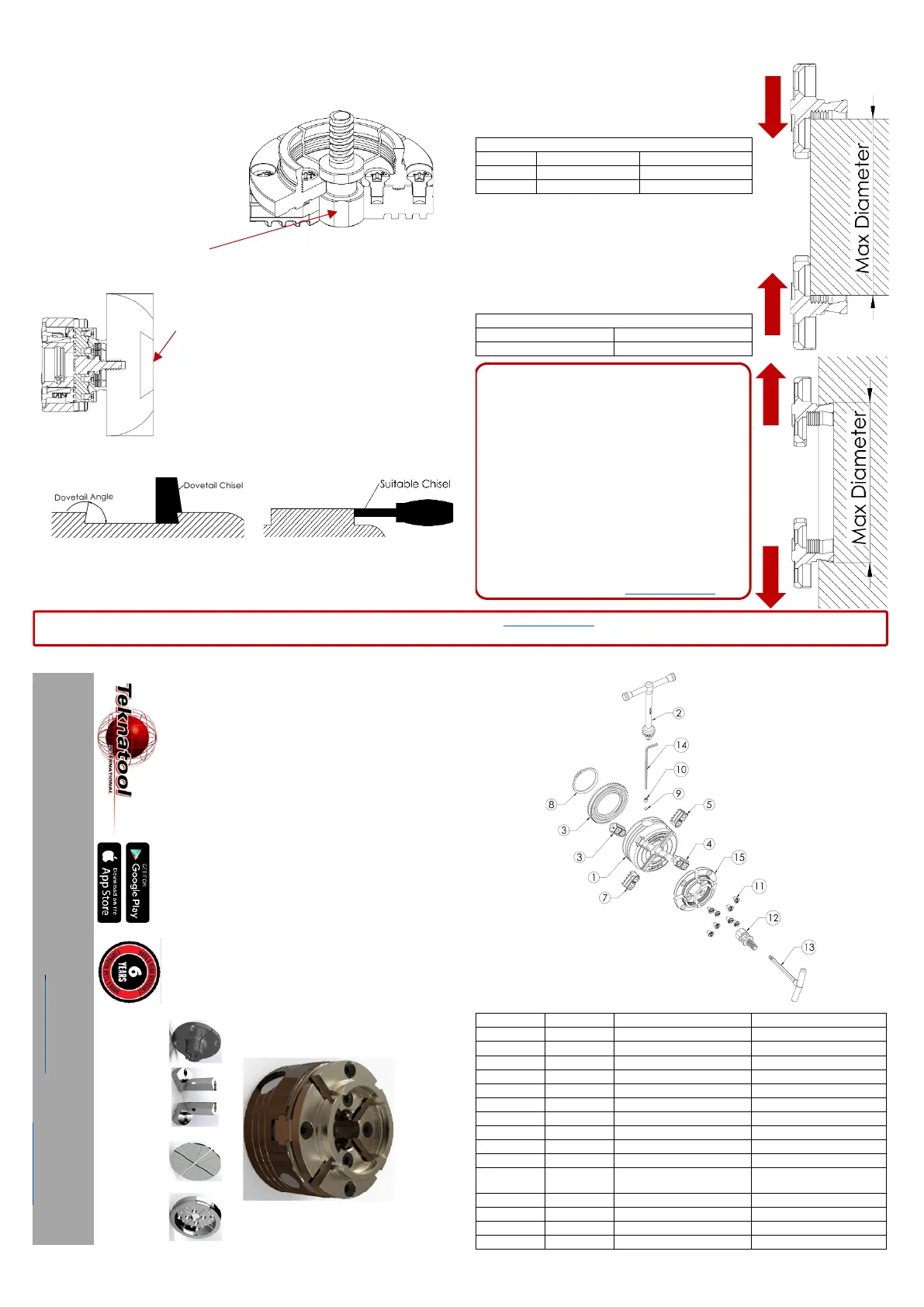

SCREW CHUCK - WOODWORM SCREW

The woodworm screw (screw chuck) provides a convenient method for holding a bowl blank

to cut a recess to mount on the PRO-TEK G3 50mm (2in) jaws.

Jaws must be mounted on the chuck before the wood worm screw – See diagram

Open the jaw slide and insert the wood

worm screw in the centre hole of the

chuck.

Position the woodworm screw as shown

in illustration

.

All 4 flat sides of the wood worm

screw should be in contact with the flat

end of the jaw slides.

The wood worm screw is used to secure the wood to

cut either a recess or spigot on the open

‘face’ end.

-

drill a hole of size 8mm (5/16in) diameter with

19mm (3/4in) depth to mount the blank using the

woodworm screw.

The wood must be seated firmly and

flat against the top surface of the mounted jaws.

For

first stage rounding of bowl blanks; extra support can

be used with live centre support from the lathe

tails

tock. See full manual online for more details.

DO NOT USE WOOD BLANKS LARGER THAN 250mm

DIAMETER X 100mm DEPTH (10inx4in)

TURNING ON A SPIGOT OR DOVETAIL

Spigot is where the jaw contracts onto the workpiece to grip.

This is mainly for box, goblet and vase turning (End grain items

with a fair degree of overhang).

EXTREME CAUTION WITH THIS OPERATION MUST BE

EXERCISED. DO NOT EXCEED 850 RPM FOR THIS OPERATION.

Spigot Diameter (For 50mm Jaws)

Dovetail is where the jaw expands into a recess of a workpiece

to grip. This operation is mainly for bowl and platter (Items with

parallel wood grain).

MUST NOT BE USED FOR ANY LONG WORK (OVER 100mm or

4 inches)

. DO NOT EXCEED 600RPM WITH THIS

OPERATION.

OUT OF BALANCE STOCK MUST BE TURNED AT THE SLOWEST

SPEED POSSIBLE.

Recess Dovetail Diameter (For 50mm Jaws)

FORMING A SPIGOT OR RECESS

Using a Nova Dovetail Chisel #6008 (or any

other suitable tool), cut into the wood

, rest the

flat side of the chisel on the bottom surface of

the recess to form a profile of between

75~80deg with 10mm (25/64in) depth.

Using a suitable chisel, turn the outer

diameter of the wood to form the spigot. The

length of the spigot should match

height of the jaws.

● Teknatool International Ltd Phone: (+64) 9 477 5600 ● Teknatool USA Phone: 727-954-3433

CUSTOMER SOLUTIONS

For all worldwide Inquiries, Repairs or Services (issues must be in writing) Email: Service@Teknatool.com

Or you can contact the retailer where you purchased your NOVA Chuck, for the contact details please see our website www.teknatool.com

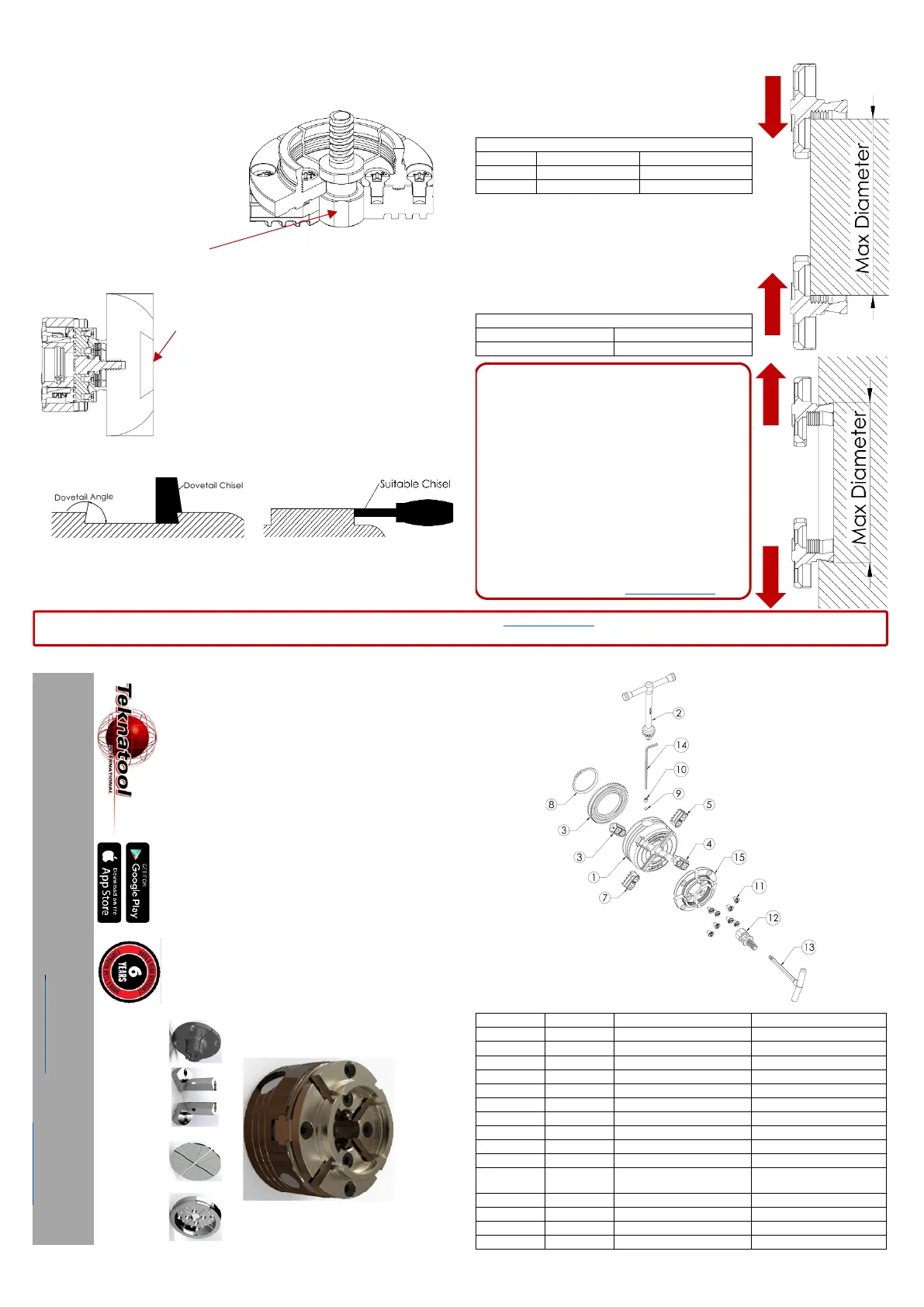

NEW AND IMPROVED FEATURES

• Rust resistant nickel-plated body for longer protection and less

maintenance.

• Stronger and more versatile PRO-TEK 50mm (2in) Jaws. Dovetail and

serrated internal profile for maximum holding power.

• Right hand, standard clockwise scroll tightening for ease of use.

• Easier to read, laser etched numbering on edge of PRO-TEK 50mm

(2in) jaws.

• Fastener upgrade to Nova Star head jaw screws. No-slip star head

for positive T-

bar handle location and better tightening power. Star

profile to minimize strip out of screw heads

• Nova Star head T-

bar Handle for easy grip and quicker tightening of

screws

• Sliding T-bar Chuck scroll key to enable easier jaw operation.

Designed and manufactured by

Teknatool International, USA and PRC © 2020 Teknatool

TM

PRO-TEK

G3 CHUCK

PRO-TEK G3 Body

11 8 CM5010182

NOVA Star head screws -

C/Sunk

PRO-TEK 50mm (2in) Jaws

ACCURACY

The PRO-TEK Chucks are sample tested from each batch

and are made to run within the following tolerance limits

on the PRO-TEK 50mm (2in) jaws:

Maximum Face/Axial Runout: 0.08mm (0.0031 in)

Maximum Radial Runout: 0.15mm (0.0060 in)

However, wood is a flexible material with varying densities

and liable to warp while turning.

Under these circumstances pursuing accuracies as above,

measured on the wood project clamped in the chuck, can be

very difficult to achieve. For most wood turning projects

there is usually little requirement to achieve such tolerances.

See trouble shooting guide for detailed guide on accuracy

in full PRO-TEK manual online at www.teknatool.com

Your Nova PRO-TEK Chuck is covered by a 6-year Limited Warranty. Go to www.teknatool.com for a full warranty statement in full version manual PRO-TEK

G3 Chuck. The full online manual also covers trouble shooting, maintenance, list of Nova lathe spindle thread inserts, jaw and chuck accessories.

Chuck is compatible with all nova jaws

including

.

Excluding jaws that are specific for Nova

Make sure this flat face is

coming in contact with the

tip of the jaw slide

(Spigot)

(Dovetail)

Download the NOVA App!

Loading...

Loading...