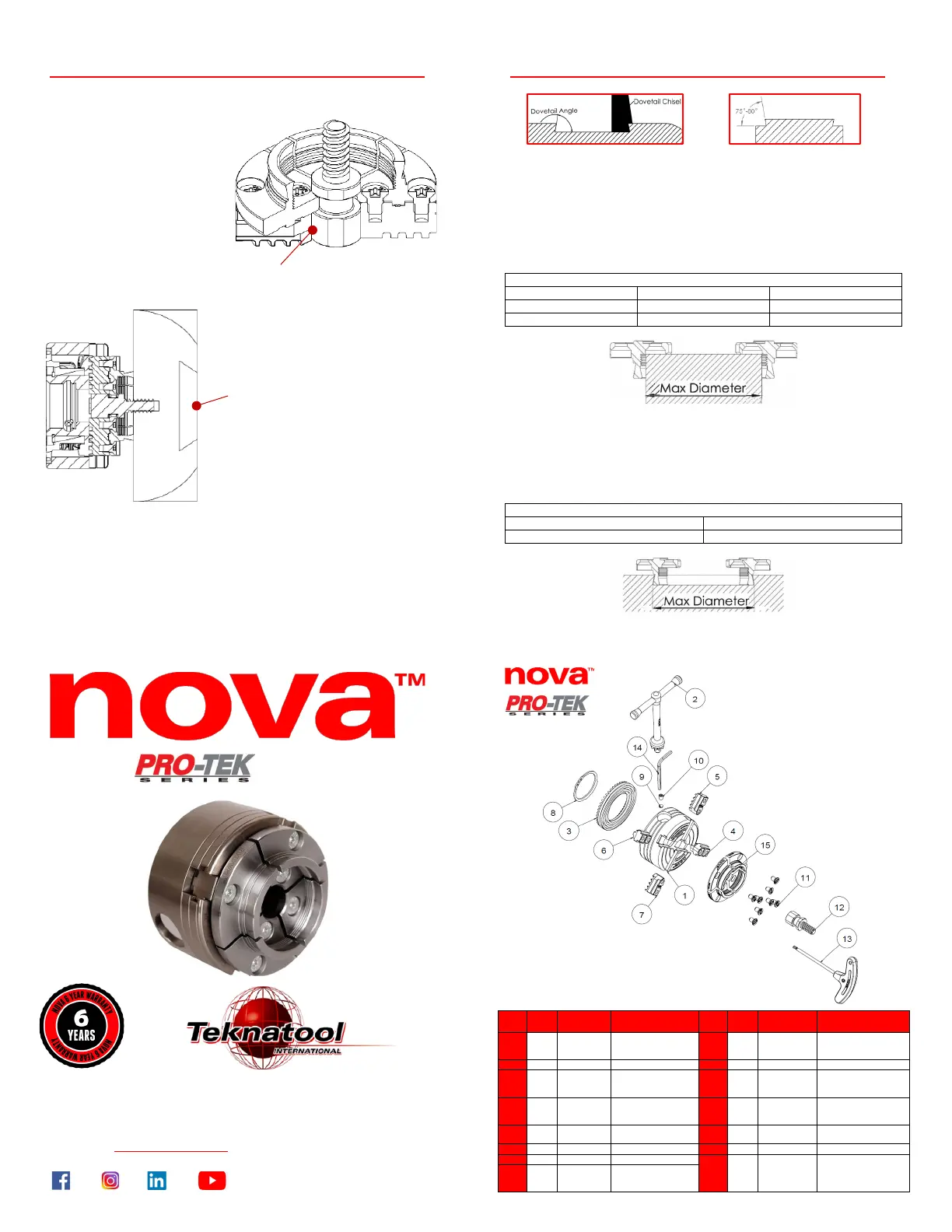

WOODWORM SCREW

The woodworm screw provides a convenient method for holding a bowl blank to

cut a recess to mount on the PRO-TEK G3 50mm (2”) jaws. Jaws must be

mounted on the chuck before the woodworm screw – See diagram below

Open the jaw slide and insert the

woodworm screw in the centre hole of

the chuck.

Position the woodworm screw as

shown in illustration.

Note: All 4 flat sides of the woodworm

screw should be in contact with the flat

end of the jaw slides.

Make sure this flat surface is in contact with the tip of the jaw slide

The wood worm screw is used to secure

the wood to cut either a mortise or tenon

on the open ‘face’ end.

Pre-drill a hole of size 8mm (5/16in)

diameter with 19mm (3/4in) depth to mount

the blank using the woodworm screw.

Side to cut mortise or tenon on

The wood must be seated firmly and flat

against the top surface of the mounted

jaws.

For first stage rounding of bowl blanks;

extra support can be used with live centre

support from the lathe tailstock.

See full manual online for more details.

Speed recommended is between 600-700 RPM for 6” diameter

and larger, or heavy pieces.

DO NOT EXCEED 700RPM for both Tenon and Mortise Operation

Teknatool International Ltd.

USA (727) 954-3433 Int’l (+64) 9 477 5600

Global Support For all inquiries, repairs, and support Email:

service@teknatool.com

or contact your local dealer.

Find a dealer closest to you by visiting www.teknatool.com

To register your warranty

or full manual visit

5432 Any Street West, Townsville, State 54321

Tel 555.543.5432 Fax 555.543.5431

5432 Any Street West, Townsville, State 54321

Tel 555.543.5432 Fax 555.543.5431

FORMING A MORTISE OR TENON

Using a Nova Dovetail Chisel #6008

(or any other suitable tool), cut into

the wood, rest the flat side of the

chisel on the bottom surface of the

recess to form a dovetail profile of

between 75~80deg with 10mm

Using a suitable chisel, turn the

outer diameter of the wood to

form the tenon. The length of the

tenon should be 3mm less than

the internal height of the jaws.

CHUCK GRIPPING DIRECTION FOR TENON ◄

A tenon is where the jaw contracts onto the workpiece to grip. This is mainly for box,

goblet and vase turning (End grain items with a fair degree of overhang).

Tenon Diameter for 50mm Jaw

◄ CHUCK GRIPPING DIRECTION MORTISE ►

A mortise is where the jaw expands into a recess of a workpiece to grip. This

operation is mainly for bowl and platter (Items with parallel wood grain).

IT IS NOT RECOMMENDED THAT A MORTISE BE USED FOR ANY LONG

WORK (OVER 100mm or 4 inches). DO NOT EXCEED 700RPM WITH THIS

OPERATION. OUT OF BALANCE STOCK MUST BE TURNED AT THE

SLOWEST SPEED POSSIBLE.

Diameter of recess for 50mm jaw mortise

REF

QTY PART # DESCRIPTION

REF

QTY PART # DESCRIPTION

48239 /

Insert Type / 1”x8tpi

23109 /

Insert Type, 1”x8tpi /

NOVA STAR

1359051 /

Insert type, 1”x8tpi /

WOODWORM

PRO-TEK 50MM (2”)

EC48 /

Insert type, 1”x8tpi /

Loading...

Loading...