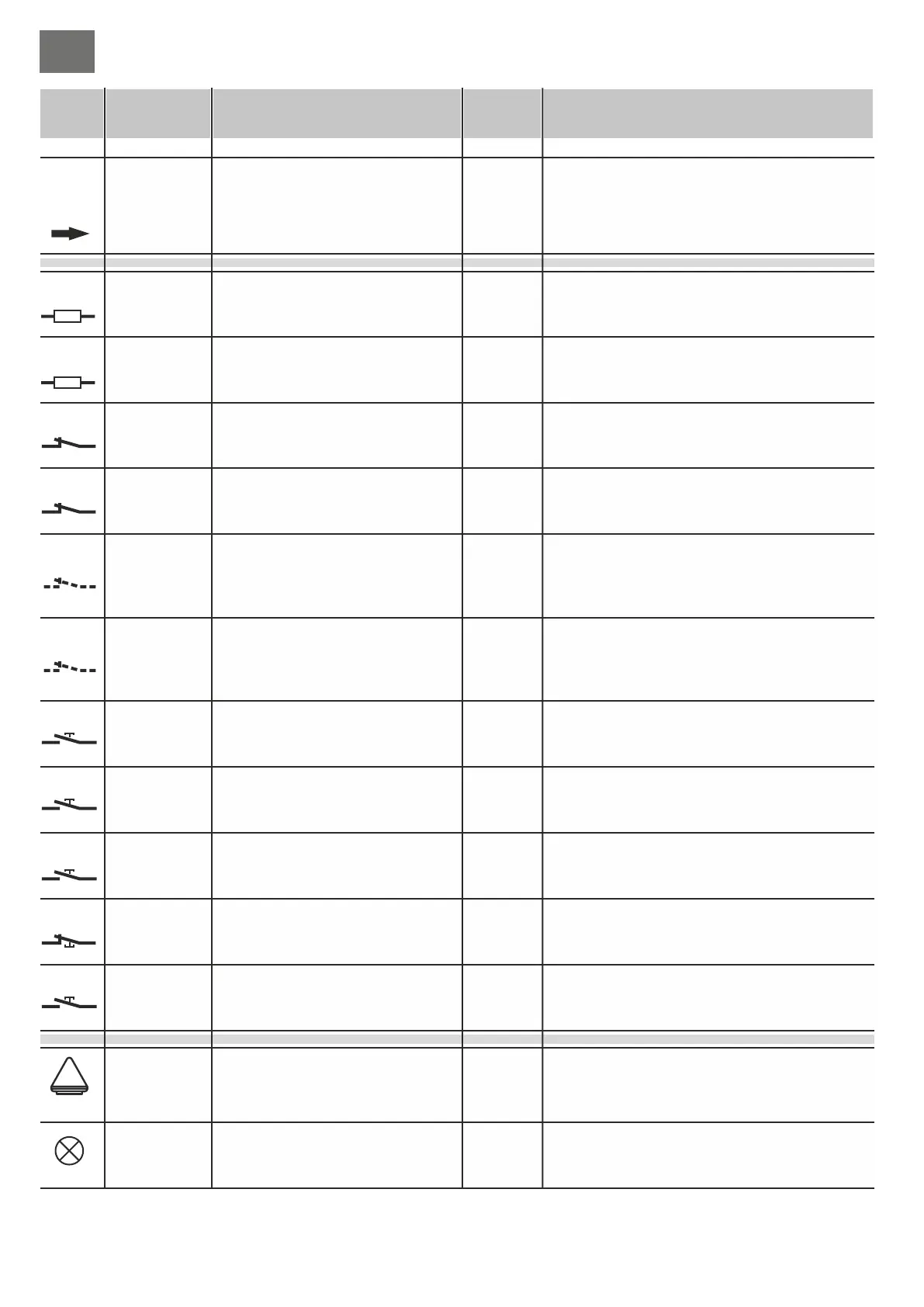

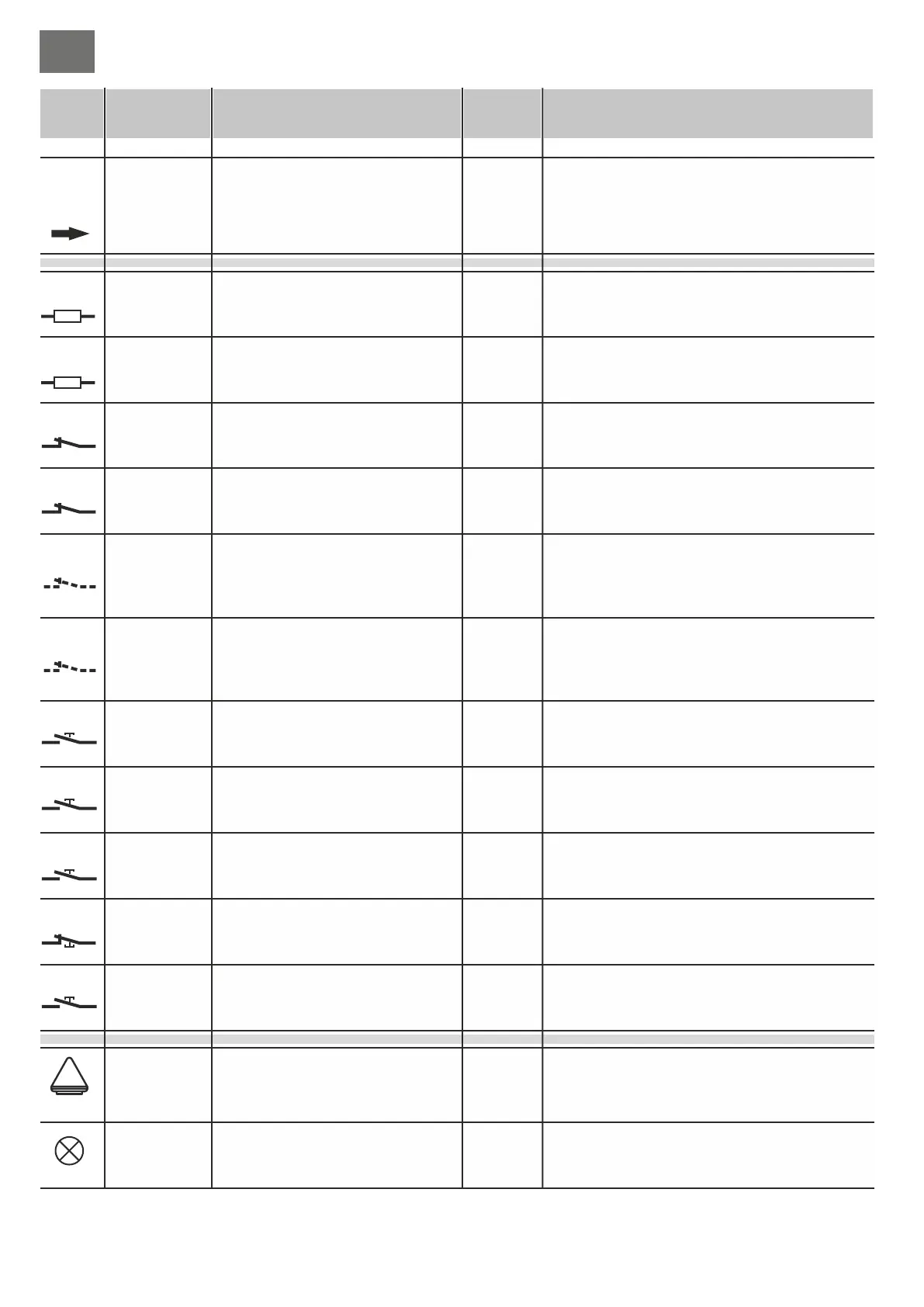

Receiver aerial input

Output for auxiliary device power

supply

Output for Transmitter / Photocell

power supply

Indicator light output

COURTESY LIGHT output

Electric lock output

WARNING LAMP output

Contact for selectable functions

Safety edge input

Cuts in during CLOSING

Safety edge input

Cuts in during OPENING

Photoelectric cell input

Photoelectric cell input

Input for selectable functions

Input for selectable functions

STOP button input

PEDESTRIAN command input

STEP BY STEP command

Command input

CLOSE

Command input

OPEN

power supply input

Encoder sensor input motor M1

Encoder sensor input motor M2

Output motor M1

Output motor M2

38 Calza

39 Cent.

31

32 (0)

33

34 (0)

35

34 (0)

18

19

36

37 (0)

16

17

28 (no)

29 (nc)

30 (c)

3,15 (com)

4

3,15 (com)

5

3,15 (com)

6

3,15 (com)

7

3,15 (com)

8

3,15 (com)

9

3,15 (com)

13

3,15 (com)

12

3,15 (com)

14

3,15 (com)

10

3,15 (com)

11

1 (L)

2 (N)

25 (-)

26 (+)

27 (D)

45 (-)

46 (+)

47 (D)

20 (CON.)

21 (CON.)

22 (AP)

23 (CH)

24 (Com)

40 (CON.)

41 (CON.)

42 (AP)

43 (CH)

44 (Com)

Function / Device Function / DeviceTerm. n. Term. n.

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

24ac/0,5A

24ac/0,5A

24ac/0,2A

230V/1A

12dc/1,5A

230V/1A

/4A

8K2/NC

8K2/NC

NC

NC

-

-

NC

NA

NA

NA

NA

230/6A

5-12V

5-12V

230/4A

230/4A

V/I max V/I max

Connection is only necessary if OC2 is inserted

e.g. photocells, external receivers or other 24Vac

devices

Output only active during the manoeuvre and the

reclosing pause period, connect the photoelectric

cell projectors so that the minimum amount of

power is used. If the jumper (part. 9 di fig. A) is set

to ON this output will be continuously active.

Status indication:

automation CLOSED – led off

during OPENING – flashes slowly

during CLOSING – flashes quickly

STOP (block) – remains lit

during the RECLOSING PAUSE – double flashing

with pause

Output active for the entire manoeuvre plus 120”

after complete closing.

Activates, for a couple of seconds at the beginning

of each opening cycle

Output active while the motor is working

See settings for dip 7 (part. 19 fig. A)

Input for closing direction enabled. Connect 8,2K safety

edges or an N.C. contact with 8,2K resistance in series (fig.

E). If unused (binding post free), set dip 1 to ON (part. 23 fig.

A).

Input for opening direction enabled. Connect 8,2K safety

edges or an N.C. contact with 8,2K resistance in series (fig.

E). If unused (binding post free), set dip 2 to ON (part. 23 fig.

A).

Travel direction inversion during closing.

If unused (binding post free), set dip 3 to ON (part. 23

fig. A).

Temporary movement block during the opening stage.

Travel direction inversion during closing.

If unused (binding post free), set dip 4 to ON (part. 23

fig. A).

See dip-switch setting 3 and 4 (part. 19 fig. A).

If unused, set dips 3 and 4 to OFF and then set dip

5 (part. 23 fig. A) to OFF.

See dip-switch setting 3 and 4 (part. 19 fig. A).

If unused, set dips 3 and 4 to OFF and then set dip

6 (part. 23 fig. A) to ON.

Blocks all functions.

If unused, set dip 7 to ON (part. 23 fig. A)

With a 2 motor installation, only M1 opens.

With a 1 motor installation it opens partially for a set

amount of time (see “programming pedestrian

opening”).

See settings for dip 1 and 2 (part. 19 fig. A)

CLOSING only command, during opening it inverts

and closes.

OPENING only command, during closing it inverts

and opens.

Connect to the 230V power supply.

For the motor-ECU connection use a separate cable

(e.g. 3x0,35) with a max. length of 10m

For the motor-ECU connection use a separate cable

(e.g. 3x0,35) with a max. length of 10m

Motor M1 moves first in the opening direction and is

delayed during closing.

An eventual electric lock should be fitted to this gate

leaf.

M2 is the second motor to move and the first one to

close.

Notes Notes

24V

24V FT

M1

M2

BSC

BSA

FT1

FT2

J1

J2

STP

PED

P/P

PC

PA

US1

230V

ENC

1

ENC

2

12V

24V

230V

230V

8K2*

8K2*

GB

GB

43

44

Loading...

Loading...