Page 24 of 24

TVP Manual (full) March 2007 CE rev 03.doc

2.07 Installation of refrigeration lines

Refrigeration lines can be made but should conform to the following norms.

Coil inlet line diameter 9.5mm – 3/8” to 15mm – 5/8”

Maximum recommended length 5m (15ft)

Coil outlet line diameter 15mm – 5/8” to 19mm – ¾ “

Maximum recommended length 5m (15ft)

Minimum insulation 60mm of closed cell “Armaflex” type

CAUTION

To maximise system performance the refrigeration lines should be as short as possible.

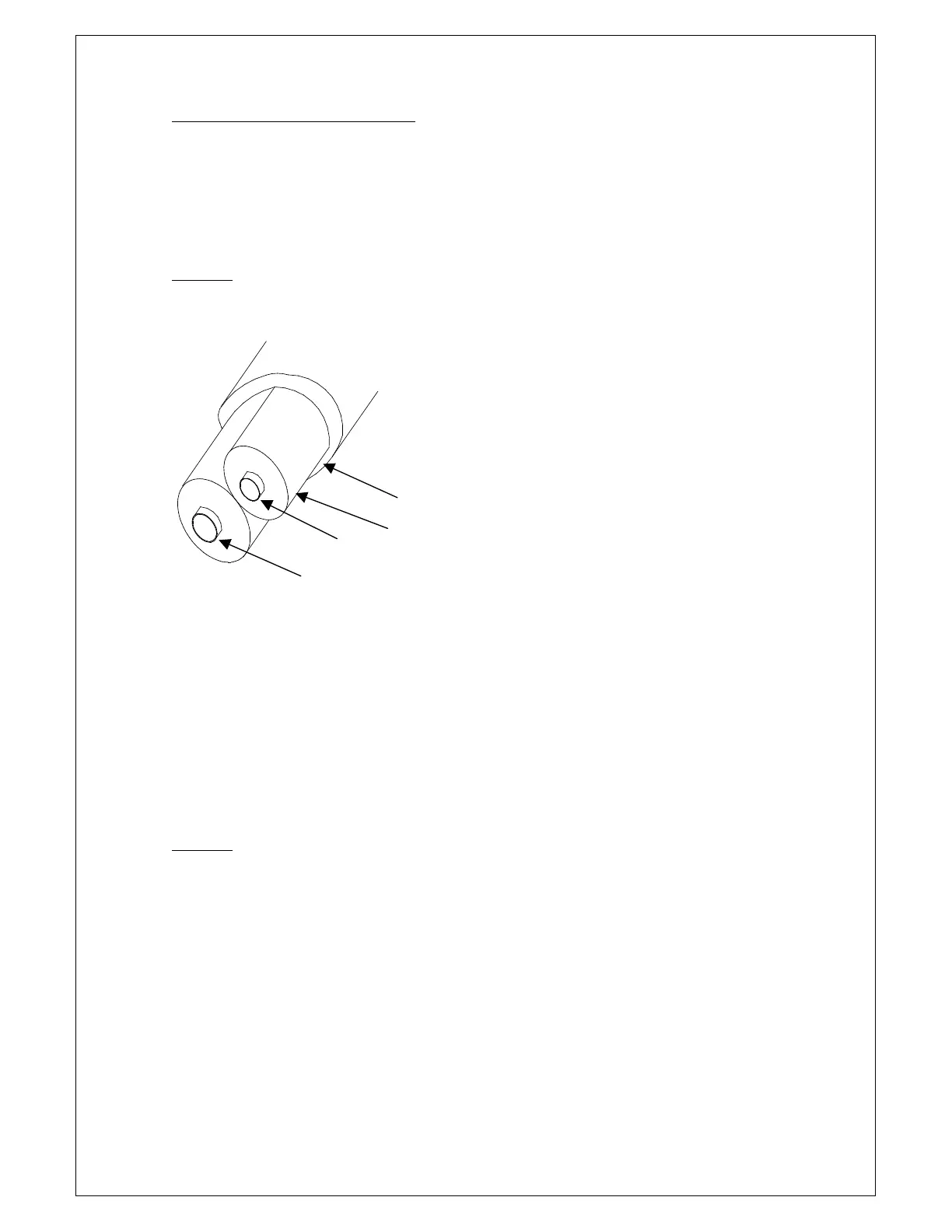

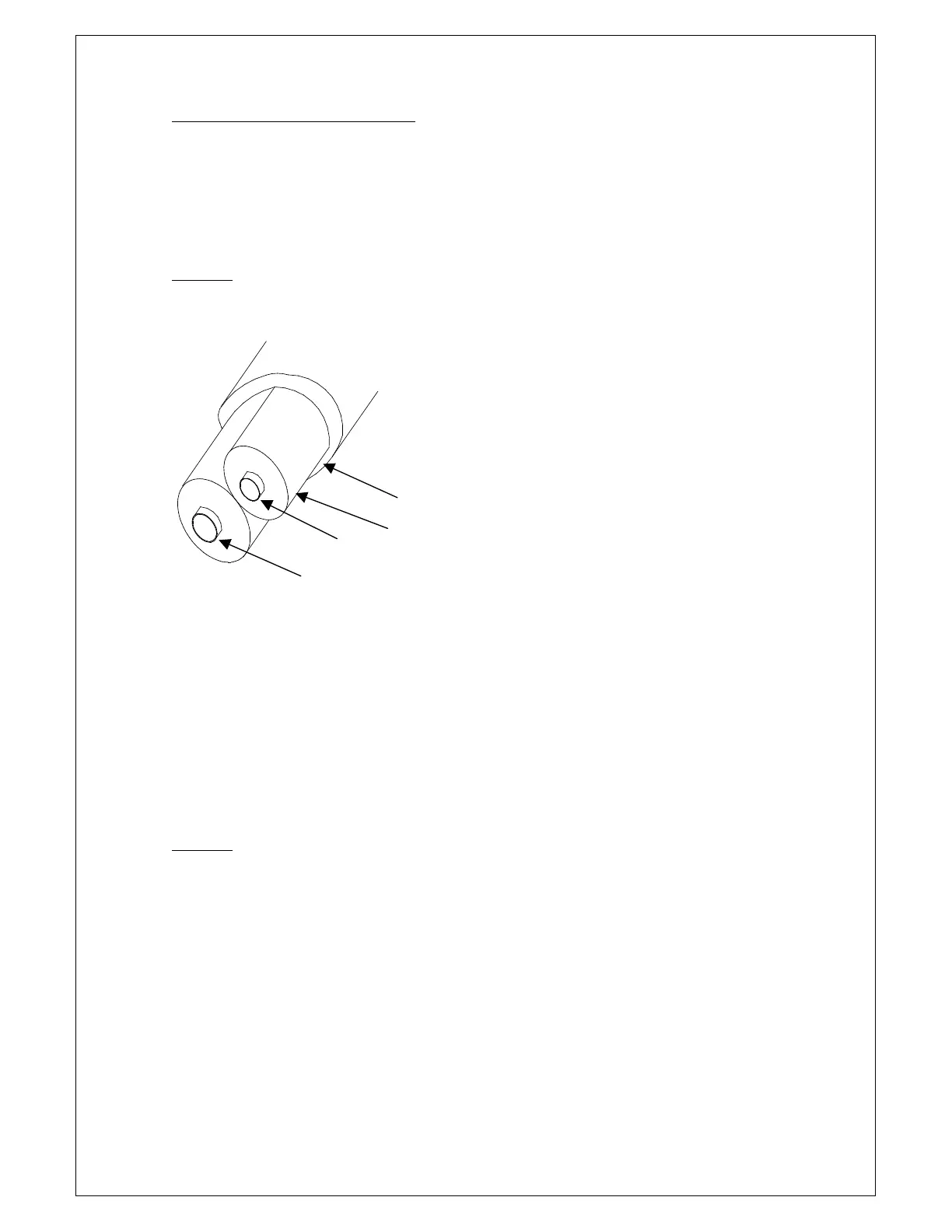

Diagram 11 Insulation of refrigerant lines

Telemark manufactures conventionally insulated refrigeration lines to order to suit your

installation.

When installing the refrigerant lines it is essential to protect the lines and fittings from the

entrance of moisture, such as water vapour, which causes rapid degradation of any foam type

insulation. An effective vapour barrier is best achieved by using the approved rubber based

impact adhesive followed by sealing of all glued edges with duct tape or 13mm electricians

type PVC tape.

CAUTION

If the lines have visible frosting or condensation is seen to leak from them during defrost or

standby, all of the line insulation must be replaced.

TVP refrigeration line connections are recessed to protect against accidental damage. When

replacing a traditional cryotrap an adapter may be required, the best solution however is to

remove the old connections from the lines replacing them with the stubs supplied in the TVP

tool kit. All copper-to-copper joints must be silver or hard soldered, soft solder is

unacceptable.

1 line into unit from coil

outlet (CO)

2 line from unit to coil

inlet (CI)

3 1

1

/

8

” (30 mm) line

insulation

4 1

1

/

8

” (30 mm) final

insulation

1

3

Loading...

Loading...