Page 49 of 49

TVP Manual (full) March 2007 CE rev 03.doc

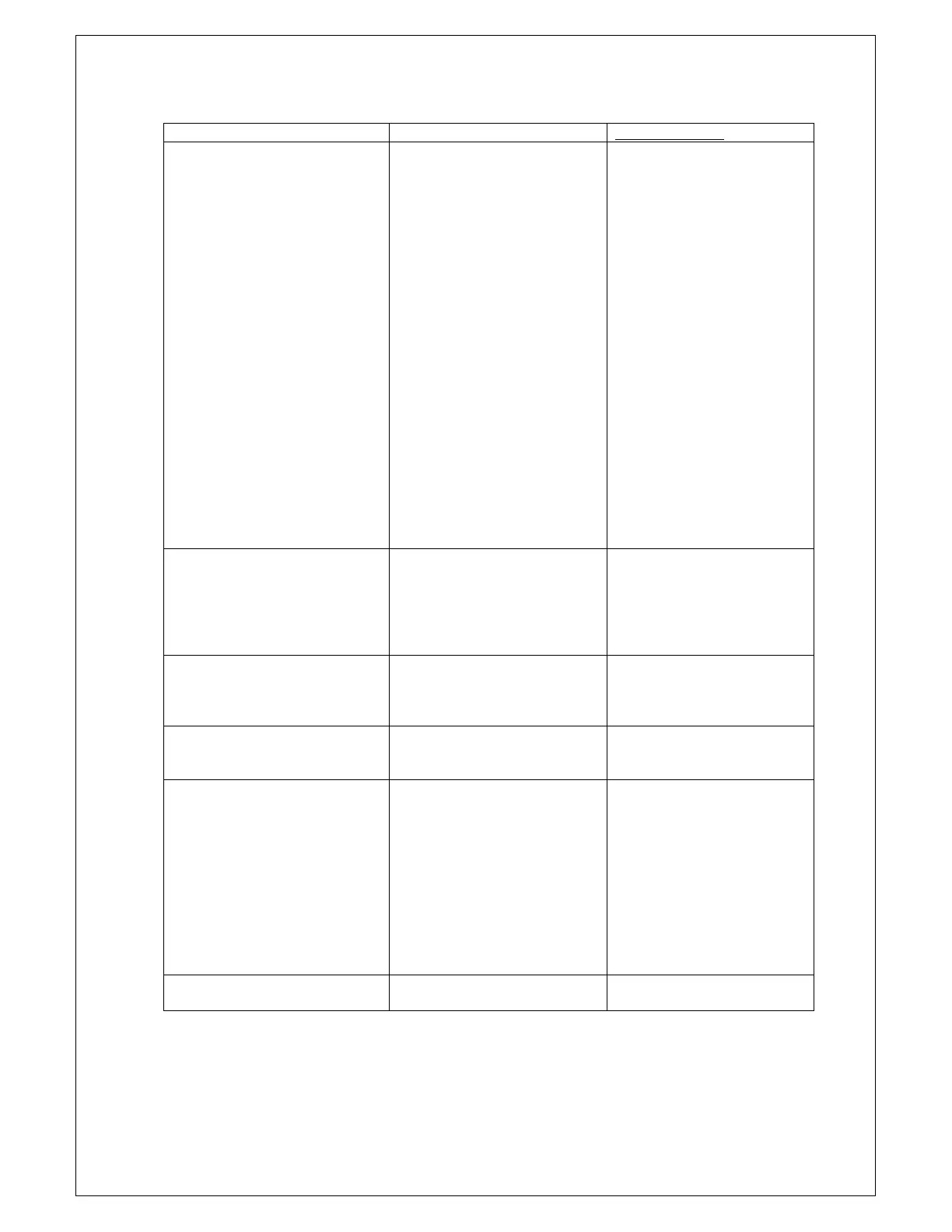

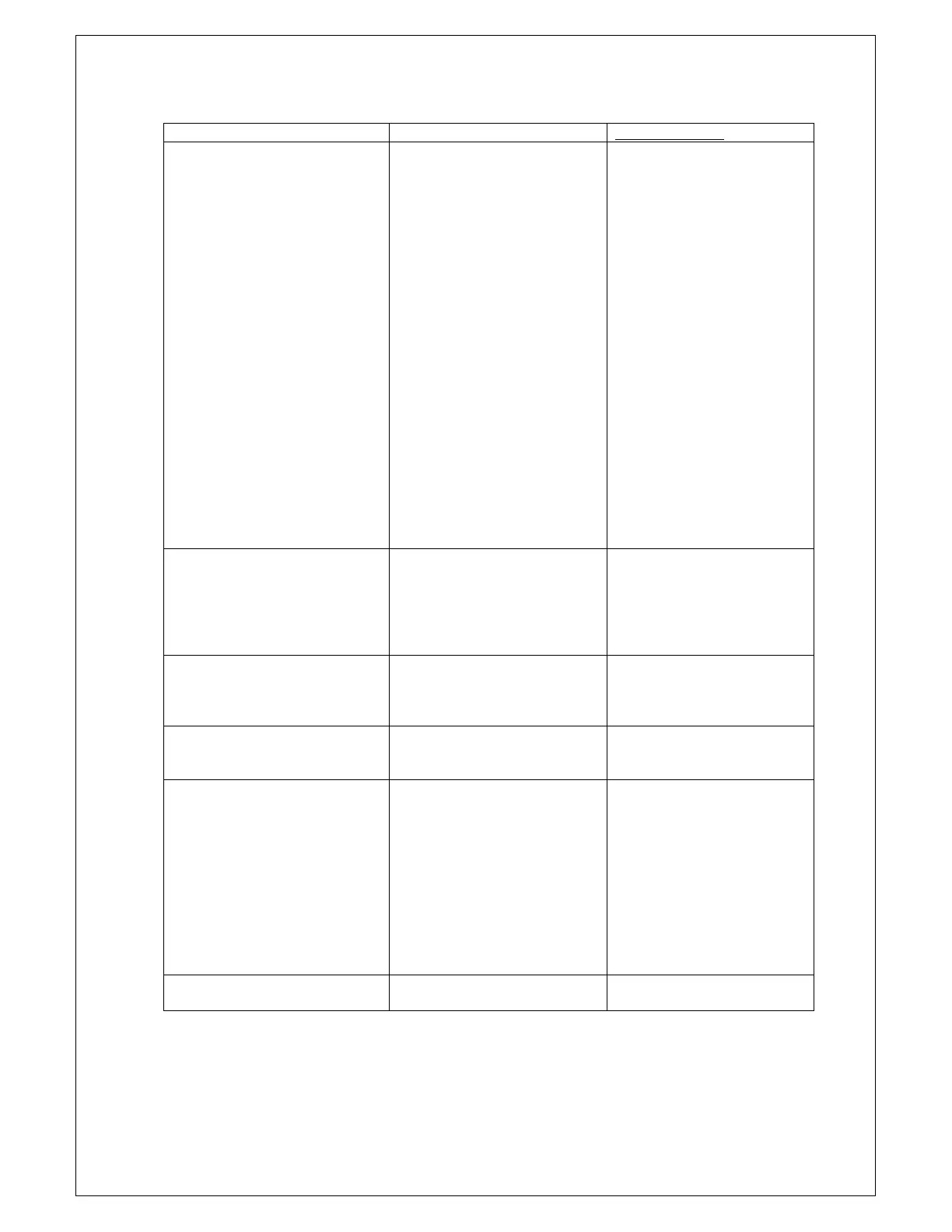

Symptom Possible Cause

Corrective Action

System has poor cooling with

small temperature differential

between CI and CO

Process problem The TVP is designed to have

a maximum stabilised

temperature differential

between CI and CO values of

20

o

c. It is possible for

absolute temperatures and in

chamber conditions to vary

for the following reasons

Ambient humidity -

Moisture levels in substrate

or poor chamber cleaning

increasing levels of out-

gassing

Poor process control

especially if substrate heaters

are part of your process.

If the cross over pressure is

too high when the TVP is

switched to cool there is a

significantly increased heat

load – aim for 5 x 10

-3

mbar

– Consult tables in section 4

System is slow to cool It typically takes 15 – 30

seconds for an appreciable

drop in the temperature at

CI. This may be longer if

remote sensors are being

used

Water temperature too low If the cooling water reading

WT is lower than 15

o

c when

the system is in standby

initial cooling is slowed

Damaged refrigeration lines

especially the cryo-coil and

return refrigerant line

Check line for blockages and

twists.

System is placed in cool too

soon after termination of

defrost

The TVP requires some time

to liquefy refrigerant to feed

the cryo-coil fully when in

cool. Try optimising your

process by lengthening the

standby period following a

defrost. Typically 1 minute

of extra standby will speed

cooling to the base

temperature by about 2

minutes

Cryo-coil has too big a thermal

mass

Redesign cryo-coil using

thinner gauge material

Loading...

Loading...