TENNEY ENVIRONMENTAL

-

LINE VOLTAGE

I

One of the most common causes of chamber malfunction is low line voltage as the power

source to the chamber. Ordinarily in this condition, the compressor motors would operate

erratically, eventually overheat and shut down. You must be certain that your equipment is

connected to a circuit with an adequate voltage and current source. An oversupply voltage

would also cause erratic operation and eventual shutdown or damage to your equipment.

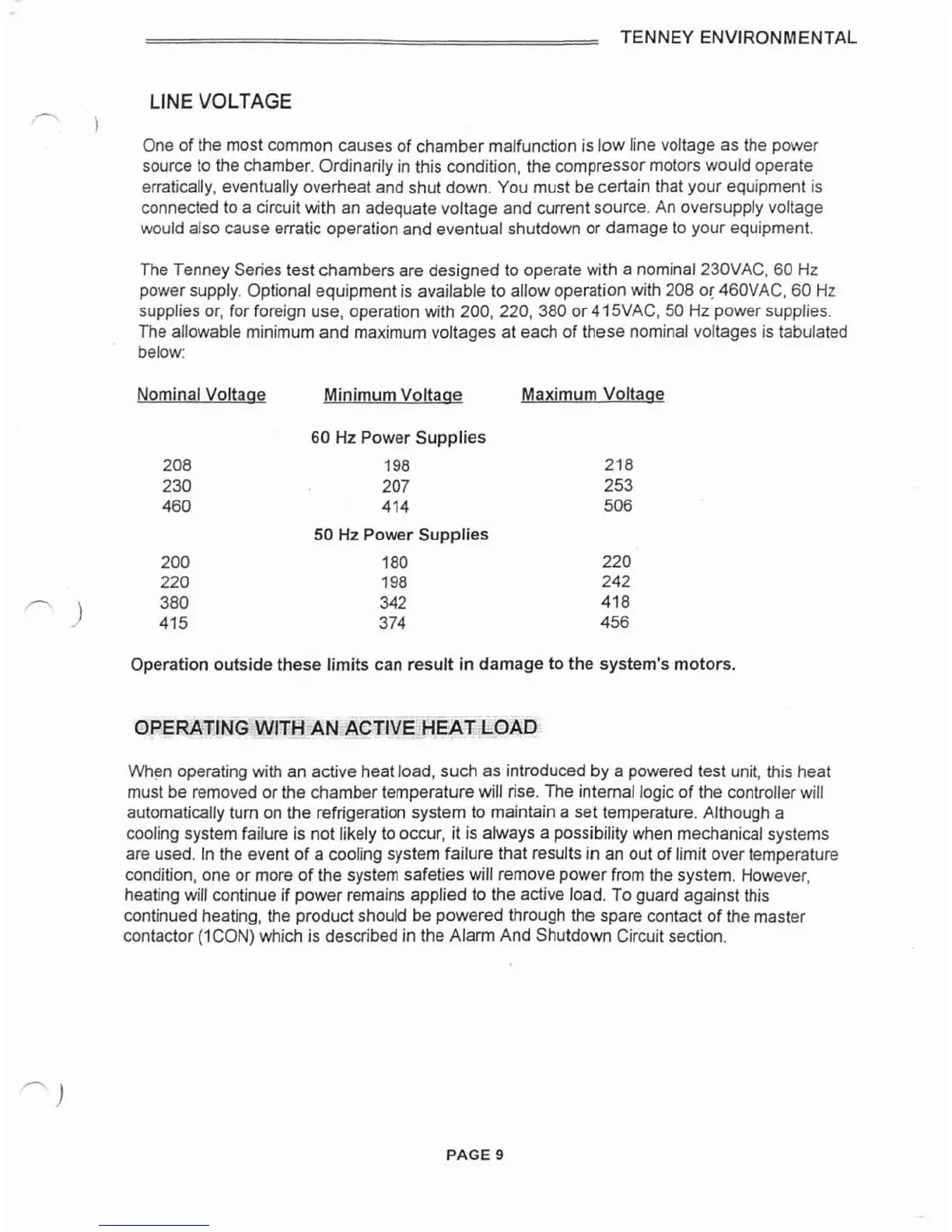

The Tenney Series test chambers are designed to operate with a nominal

230VAC, 60

Hz

power supply. Optional equipment is available to allow operation with 208 or460VAC, 60

Hz

supplies or, for foreign use, operation with 200, 220, 380 or415VAC. 50

Hz

power supplies.

The allowable minimum and maximum voltages at each of these nominal voltages is tabulated

below:

Nominal Voltaae Minimum Voltaae Maximum Voltaae

60

Hz

Power Supplies

198 21 8

207 253

414 506

50

Hz

Power Supplies

180 220

198 242

342

418

374 456

Operation outside these limits can result

in

damage to the system's motors.

OPERATING WITH-AN

ACTIVE

HEAT LOAD

When operating with an active heat load, such as introduced by a powered test unit, this heat

must be removed or the chamber temperature will rise. The internal logic of the controller will

automatically turn on the refrigeration system to maintain a set temperature. Although a

cooling system failure is not likely to occur, it is always a possibility when mechanical systems

are used. In the event of a cooling system failure that results

in

an out of limit over temperature

condition, one or more of the system safeties will remove power from the system. However,

heating

will

continue if power remains applied to the active load. To guard against this

continued heating, the product should be powered through the spare contact of the master

contactor (ICON) which is described in the Alarm And Shutdown Circuit section.

PAGE

9

Loading...

Loading...