TENNEY ENVIRONMENTAL

-

TEMPERATURE CONTROL

-

WATLOW

942

CONTROLLER

1

Temperature conditions are attained and controlled by a Watlow 942 microprocessor based

controller. Temperature measurements are made utilizing a 100 ohm platinum RTD sensor.

This controller features dual outputs, auto-tuning control with 24 step program capability and

easy fixed set point operation.

Heating of the chamber is accomplished with the time proportioned (PID) Output

ICI-01 of the

controller, which

turns on a triac in the heater circuit supplying power to the heater elements.

Cooling of the chamber is accomplished with

ONIOFF Output ICI-02 of the controller, which

energizes a contactor supplying power to the refrigeration circuitry.

IMPORTANTI

Output 1CI-02 is set up for ONIOFF control and the PID value is set to zero

Do not change the PID value for channel two under any circumstance!

--

Corn~ressor Turn-On

Loaic

In determining when to turn the refrigeration system on or off, the controller's logic will compare

the following signals and setpoints.

1.

Actual Chamber Temperature

2.

Setpoint Temperature

3.

Hysteresis

4.

Deadband

-

)

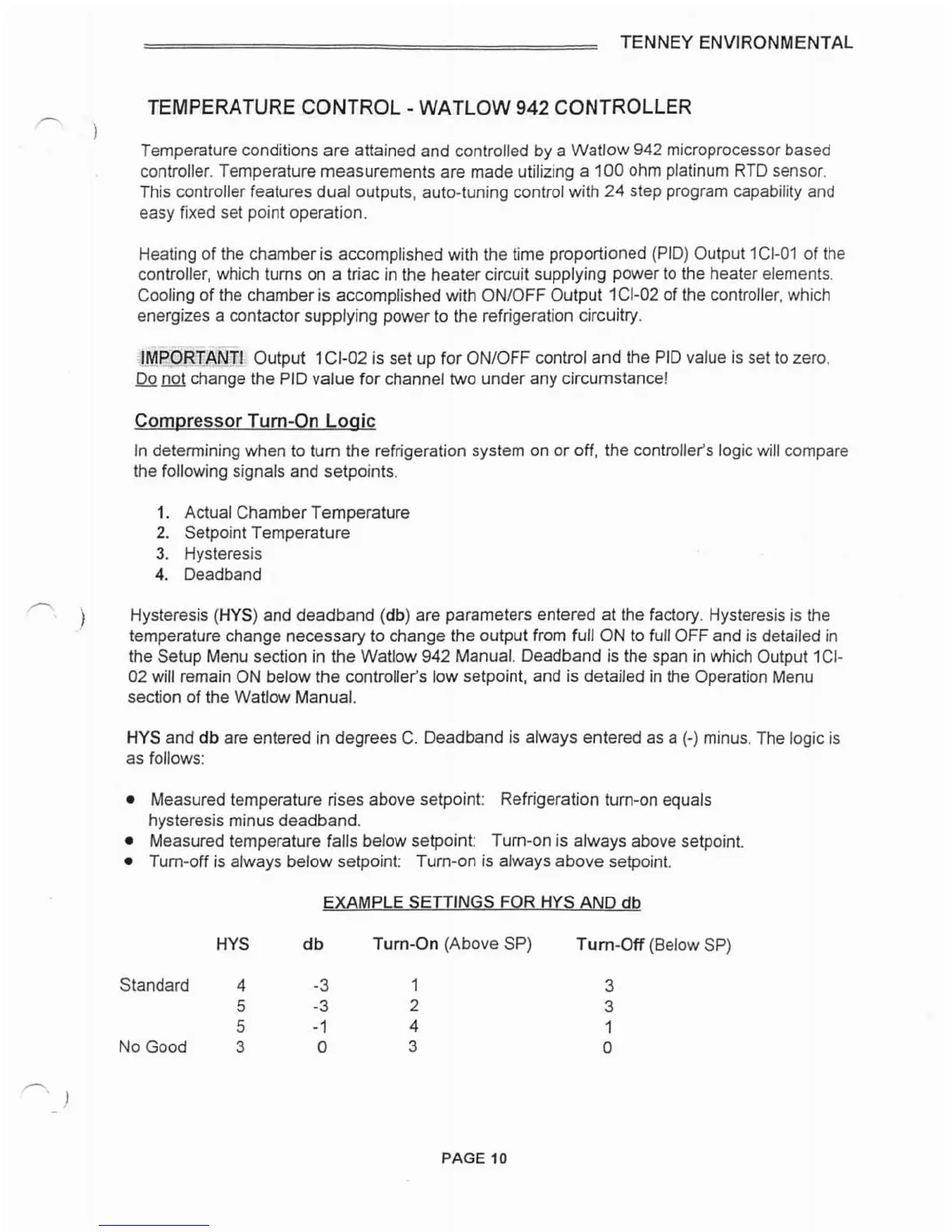

Hysteresis

(HYS)

and deadband

(db)

are parameters entered at the factory. Hysteresis is the

temperature change necessary to change the output from full ON to full

OFF

and is detailed in

the Setup Menu section in the Watlow 942 Manual.

Deadband is the span in which Output ICI-

02 will remain ON below the controller's low setpoint, and is detailed in the Operation Menu

section of the Watlow Manual.

HYS and

db

are entered

in

degrees

C.

Deadband is always entered as a

(-)

minus. The logic is

as follows:

Measured temperature rises above setpoint: Refrigeration turn-on equals

hysteresis minus deadband.

Measured temperature falls below setpoint: Turn-on is always above setpoint.

Tum-off is always below setpoint:

Turn-on is always above setpoint.

EXAMPLE

SETTINGS FOR HYS AND

db

HYS

db

Turn-On (Above SP) Turn-OR (Below SP)

Standard 4

-3

1

5

-3

2

5

-

1

4

No Good

3 0

3

Loading...

Loading...