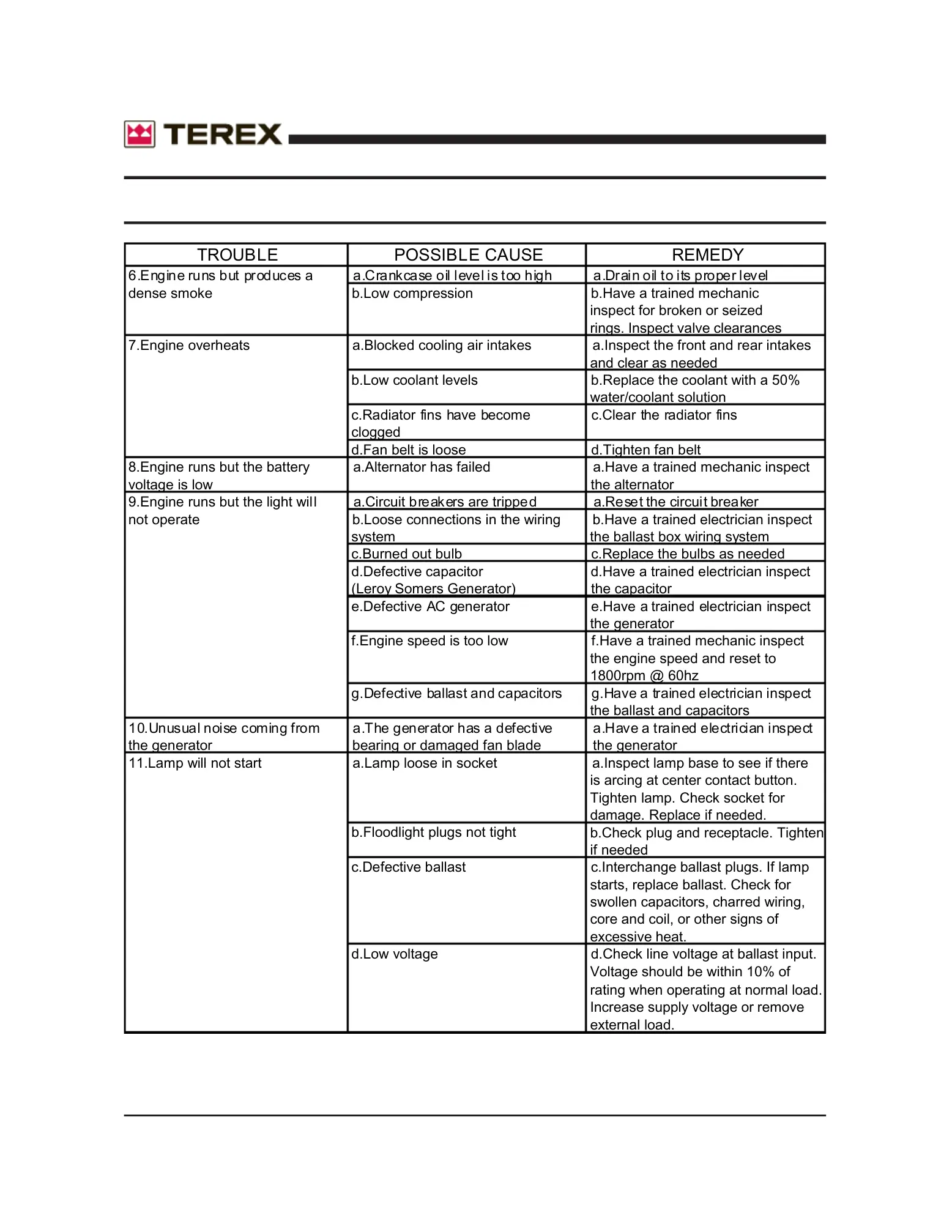

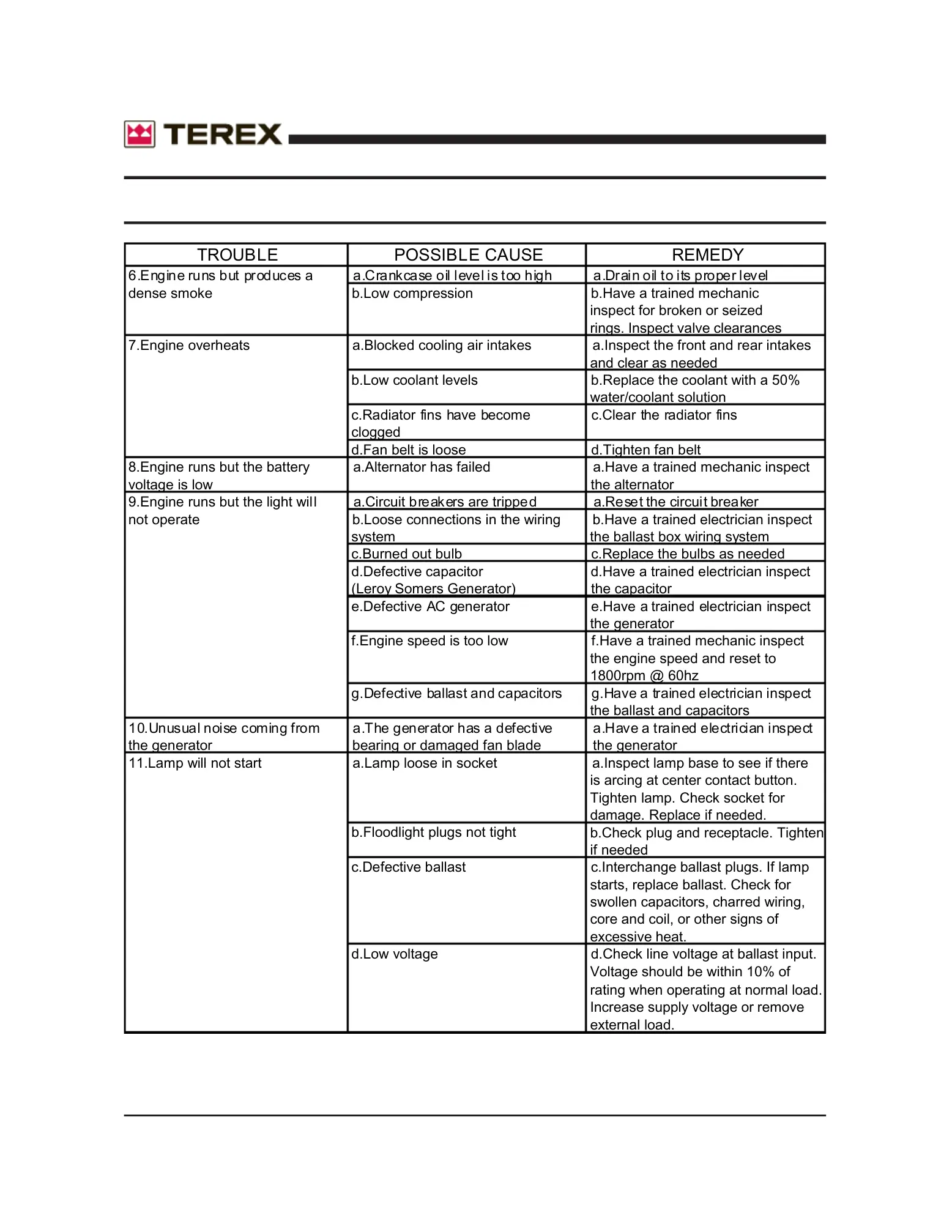

inspect for broken or seized

rings. Inspect valve clearances

the engine speed and reset to

the ballast and capacitors

is arcing at center contact button.

Tighten lamp. Check socket for

damage. Replace if needed.

b.Floodlight plugs not tight

starts, replace ballast. Check for

swollen capacitors, charred wiring,

core and coil, or other signs of

Voltage should be within 10% of

b.Check plug and receptacle. Tighten

rating when operating at normal load.

Increase supply voltage or remove

Loading...

Loading...