PULLER-TENSIONER

Model: AFS404

Manual: MI-AFS404-609-01-GB

5.5 USING OF ELECTRONIC SPEED SYNCHRONIZER DEVICE (OPTIONAL)

The machine could be provided with an electronic speed synchronizer

device as a optional package; to activate operate on the selector (table 3,

pos. 9) (rightwards) on the master machine.

This device allow to have the same recovering speed of each connected machines.

5.6 ROPE LOCKING CLAMP (OPTIONAL)

When the machine are connected the proper selector on the master machine operate on all the

clamps of the connected machines.

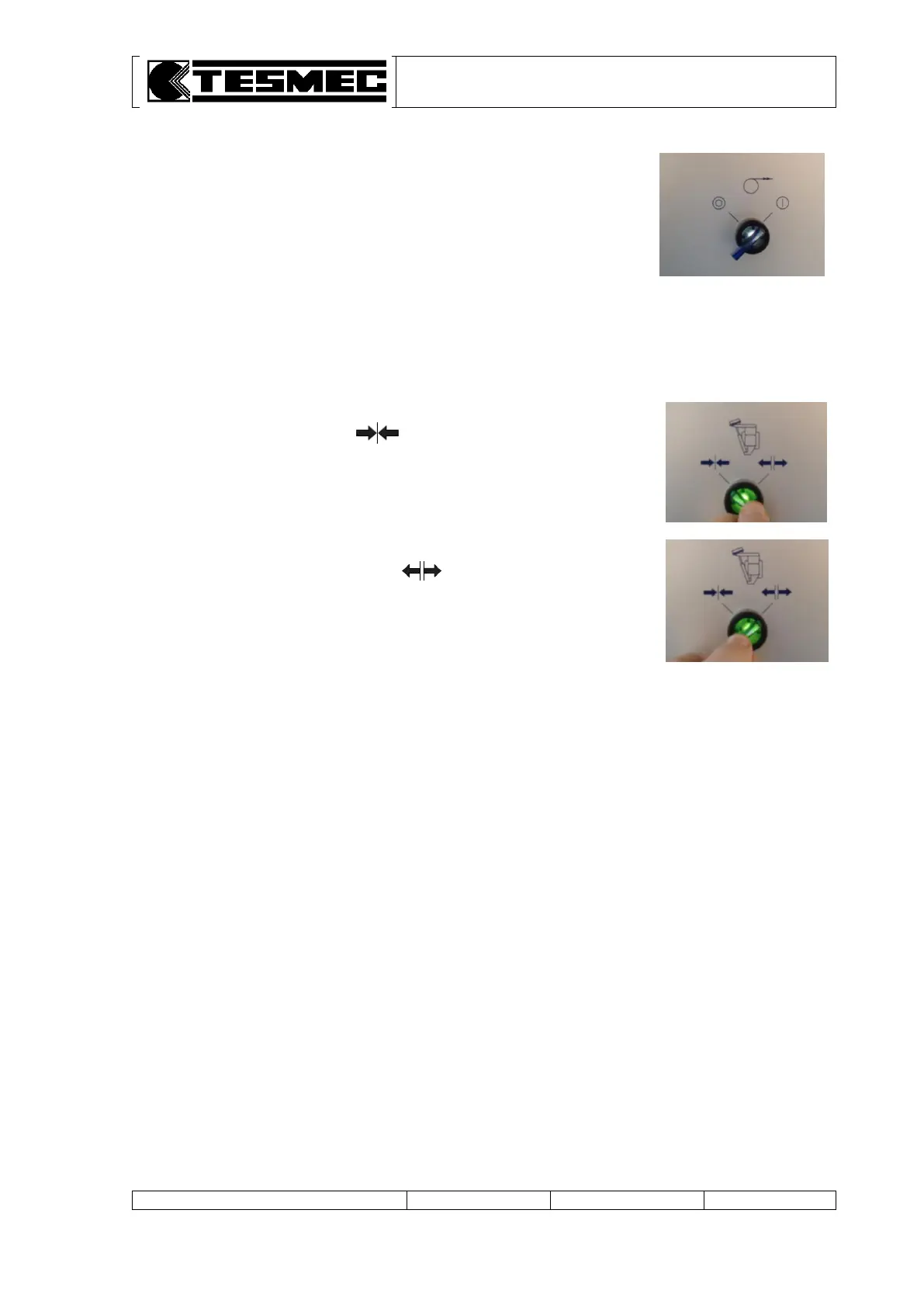

To engage the rope locking clamp, turn the proper selector on the master

machine (table 3, pos.30) on position (leftwards - blocked – no

light) and keep it in position for a few second to allow the complete closing

of the clamp.

To dis-engage the rope locking clamp, turn the proper selector on the

master machine (table 3, pos.30) on position (rightwards – free –

green light) and keep it in position for a few second to allow the complete

opening of the clamp.

5.7 ALARM CONDITION WHEN USING CONNECTED MACHINES

When using connected machines some situation generate alarm condition with switch on of the

alarm light on the main control panel of the machine where the alarm is generated.

5.7.1 STRINGING LENGTH ERROR

When the electronic speed synchronizer system is active, an eventual difference of stringing length on

the independent ropes larger than a default value programmed (generally 6 m) generate an error and

the stringing operations stops on all the connected machines.

To reset the alarm move the joy-stick to neutral on the master machine and dis-engaged the speed

synchronized selector; check the cause of the alarm on the line (ex. Operation of the pull programming

system and arrest of one rope line) before to re-start.

5.7.2 SWITCH ON THE MACHINE WITH CONTROL NOT IN NEUTRAL

When the machine is switched on with joy-stick not in neutral position, an alarm is generated and the

capstans don’t move.

5.7.3 EMERGENCY STOP

Pressing the emergency stop in one of the connected machines generate the stop of the engine of the

single machine where the stop has been activated and the stop of the movement of all the remaining

connected machines, where the diesel engine remain switched on.

To reset the alarm move the joy-stick to neutral on the master machine before to dis-engaged the

emergency stop on the machine in emergency situation.

Loading...

Loading...