PULLER-TENSIONER

Model: AFS404

Manual: MI-AFS404-609-01-GB

7.8 RADIATOR’S MAINTENANCE

At least once a year, or more in case of use in dusty places, is foreseen a blowhole with compressed

air of the radiant mass of the radiators.

ATTENTION: in order to make this operation the one in charge of maintenance, besides

wearing all the protection devices already shown in this manual, must also wear a device for

protecting respiratory organs.

7.9 GREASING

Grease 2-3 times per day the crown gear of the bull-wheels using the suitable greaser (table 2, pos. 2).

Weekly grease all the other parts subjected to rotation or translation and that not foreseen a forced

lubrication or an automatic greasing.

Use IP ATHESIA GR2 (ISO XBCEA 2) grease or equivalent of another trademark based on the

enclosed "SUGGESTED LUBRICANTS" table.

7.10 OTHER PERIODIC OPERATIONS

When cleaning the machine, avoid direct jets of water or steam on the components of the electric

system of the machine and on the control panel.

For the other periodic operations, refer to the summary table for the ordinary maintenance (see next

paragraph).

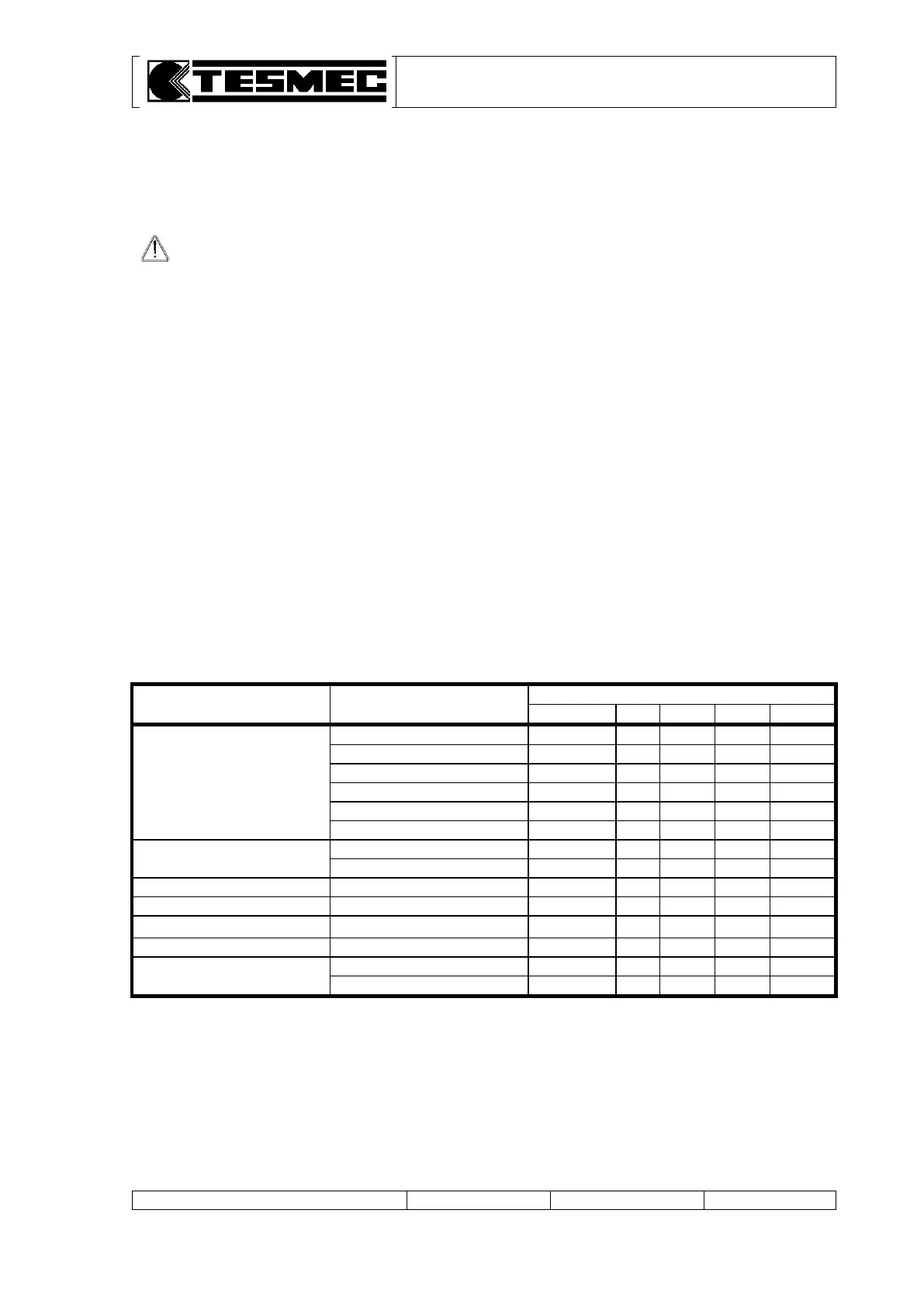

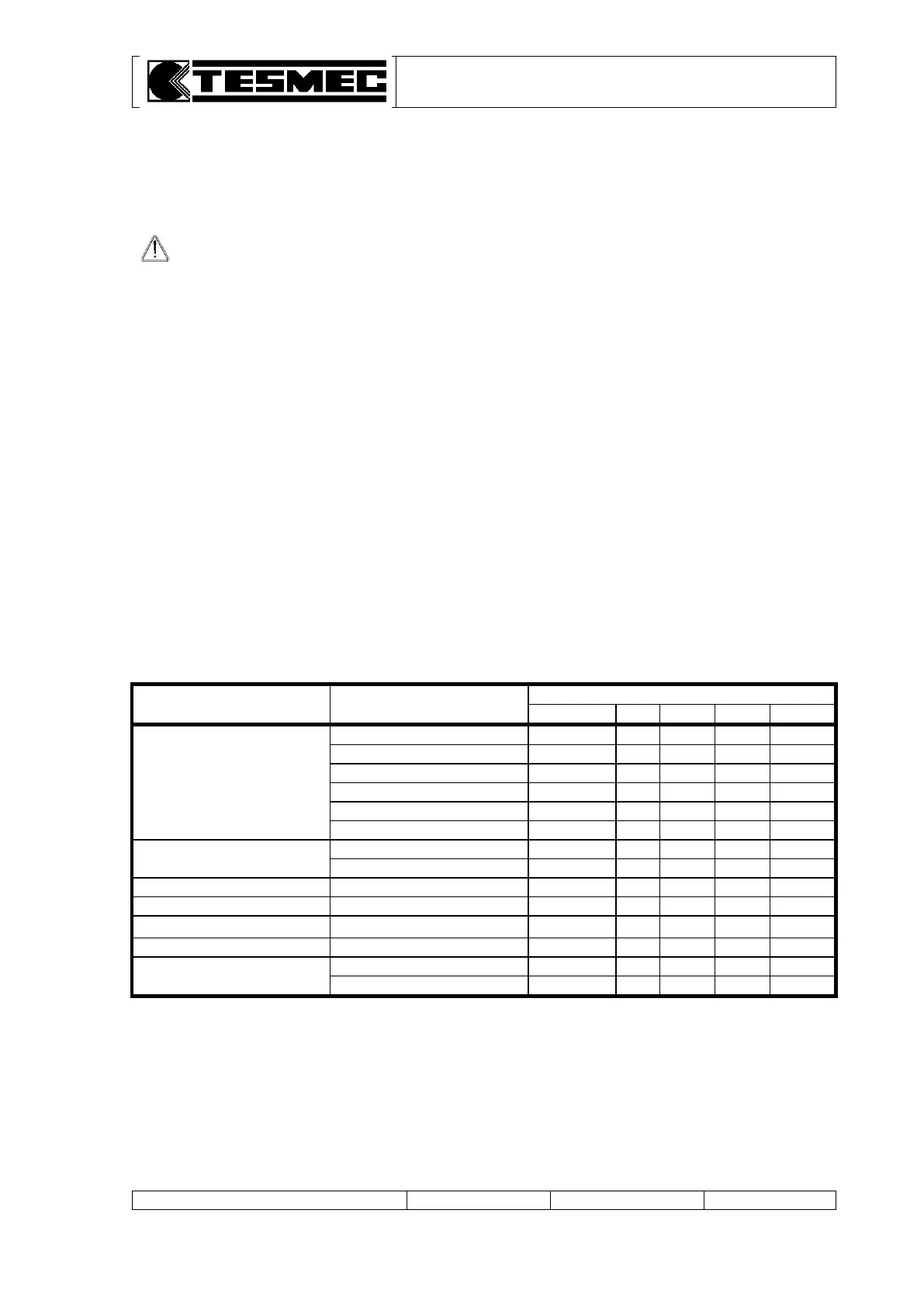

7.11 SUMMARY TABLE FOR ORDINARY MAINTENANCE

In this card are listed main operation of periodic maintenance and relevant intervals.

Legend:

CL Check the level (and possible filling up)

GR Grease

ST Replace

ST1 Replace (only for the first intervene)

VF Check

(*) Or in any case every year

(**) Check the discs wear condition after an emergency stop

(***) For further information see the engine booklet

Loading...

Loading...