Models 3940 and 3949 ________________________________________________________________Installation and Set-Up

2.12 1900140 IR CO2 Option

This section applies to units with the 1900140 IR CO

2

option only.

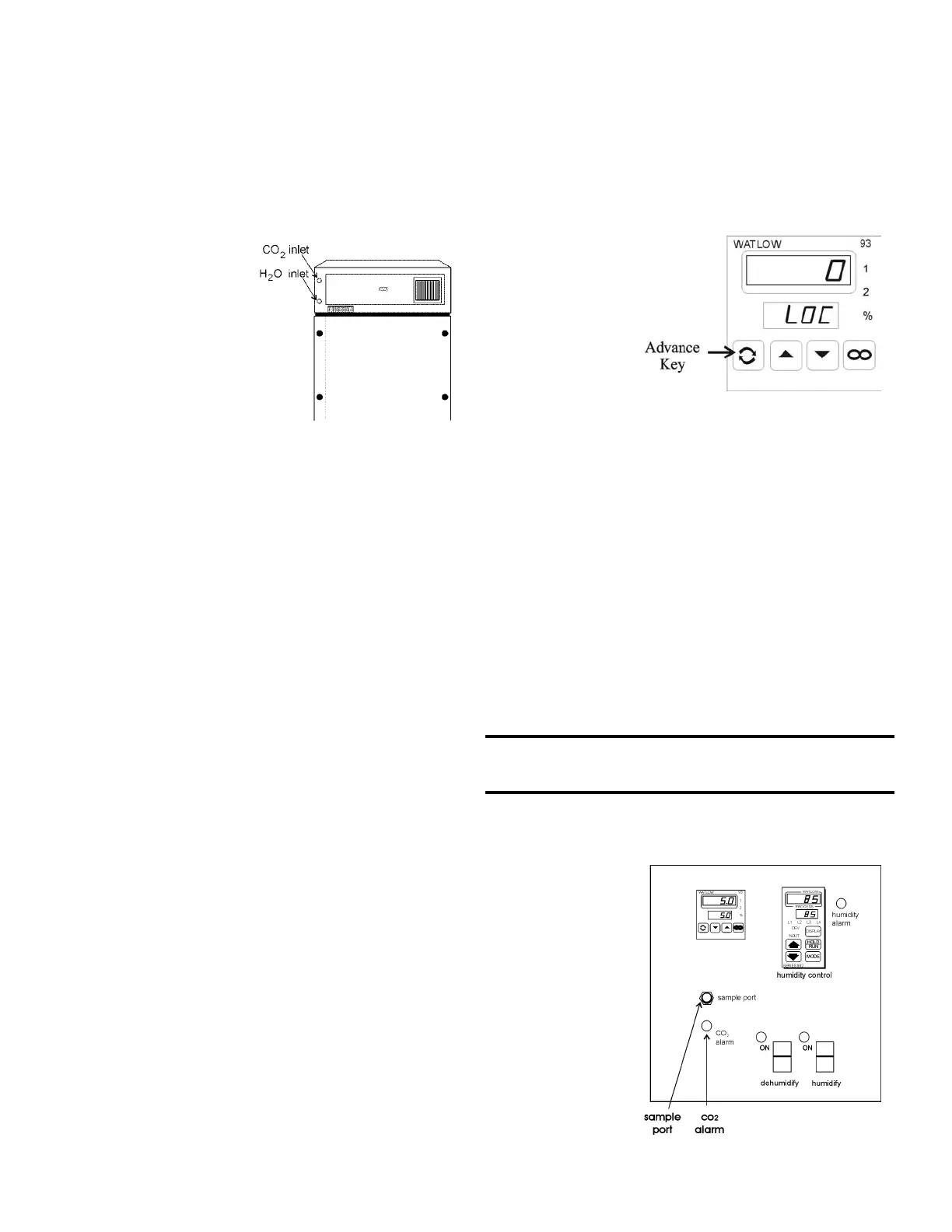

a. Connecting the CO

2 Source (Refer to Figure 2-3)

For the most economical use, the liquid CO

2 supply tanks

should be without siphon

tubes, so that only CO2 gas

enters the incubator injection

system. Two tanks may be

joined together with a mani-

fold to ensure a continuous

CO

2 supply.

Install a two-stage pres-

sure regulator, with indicating

gauges, at the supply cylinder

outlet. The high-pressure

gauge should have an indicat-

ing range of 0 to 2000 psig to

monitor tank pressure. The

low-pressure gauge should

have an indicating range of 0

to 30 psig to monitor input

pressure to the incubator injection system. A suitable two-stage

pressure regulator is available.

The CO

2 source must be regulated at a pressure level

between 5 and 10 psig. Higher pressure levels may damage the

CO2 control system. The user should determine the most eco-

nomical pressure level, between 5 and 10 psig appropriate for

the desired CO

2 percentage in the chamber. Use only sufficient

pressure to maintain recovery time after door openings.

To connect the CO

2 supply:

· Insert the copper tubing provided with the unit as far as it

will go into the nut of the CO2 connection.

· Turn the nut until it is finger tight.

· For reference, scribe the nut at the 6:00 position.

· While holding the fitting body steady with a wrench, tighten

the nut 1-1/4 turns until the mark is at the 9:00 position.

· Securely attach the CO

2 line to the open end of the copper

tubing.

· Check the tubing connection for leaks.

b. Setting the CO

2

Content

The Watlow 93 CO

2 controller's upper display shows

the actual CO2 content inside the chamber. The lower display

shows the CO2 setpoint.

Before setting the CO

2 Content, allow the chamber tempera-

ture and humidity to stabilize. Do not open door during the sta-

bilization period.

To set the CO

2 content, press the up or down triangles

on the Watlow 93 Controller.

c. CO

2 Controller Calibration

If it should become necessary to calibrate the CO

2 con-

troller, perform the following procedure. From the standard

operating display (setpoint in bottom display, actual CO

2 reading

in the upper display):

Enter the Setup Menu by pressing the t up-arrow and

6down-arrow keys

simultaneously on the

Watlow 93 controller for

three seconds. The

lower display shows the

Lock parameter, and the

upper display shows its

current level. Press

the6 down-arrow until

0 is displayed. Then,

use the Advance key to

move through the menus

until the "CAL" prompt appears.

Once at the "CAL" prompt, press thet up-arrow or 6

down-arrow to add or subtract the percentage of CO

2 to make

the display accurate. Press the Advance key until LOC appears.

Press the t up-arrow key to place "2" in the upper display.

Continue to press the Advance key until the setpoint display

appears.

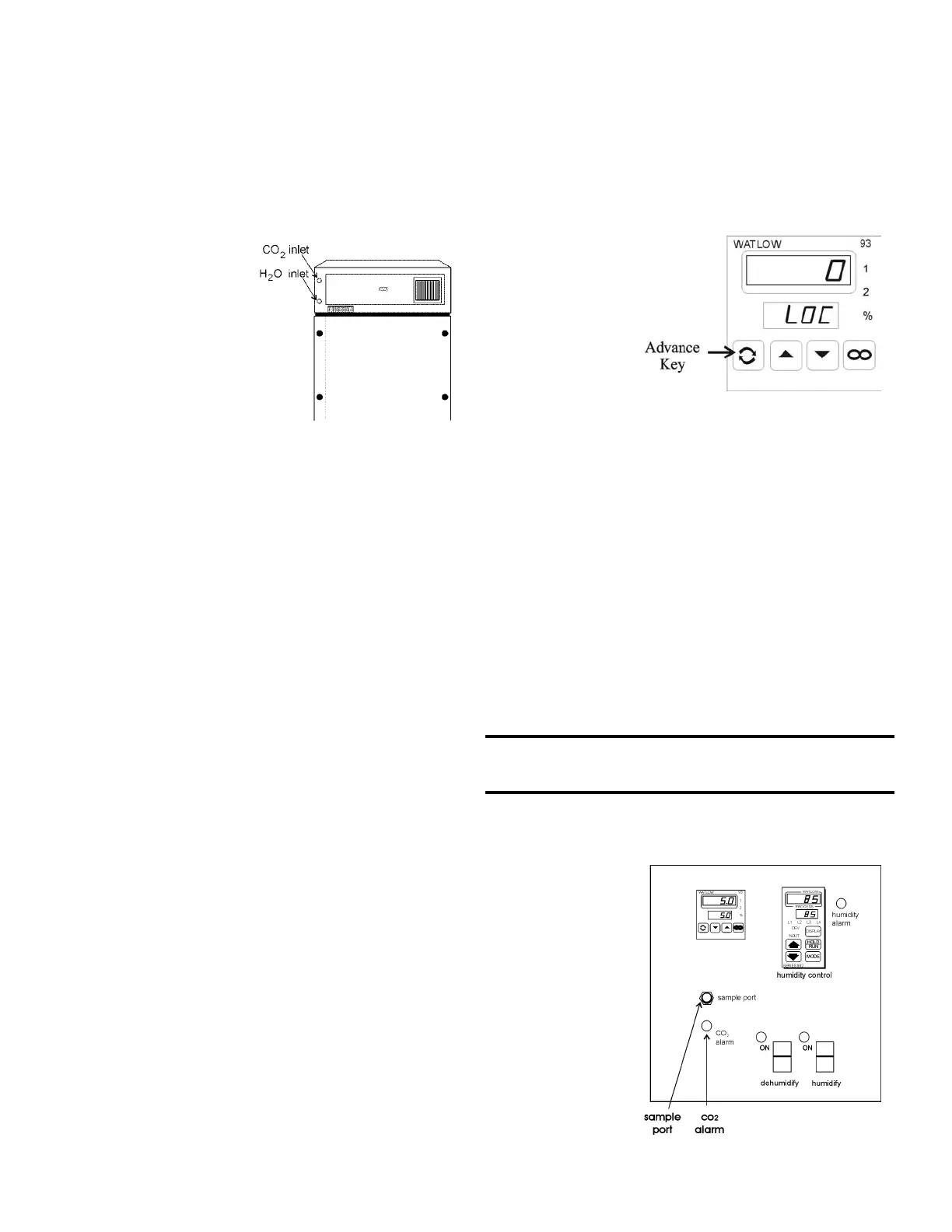

d. CO

2

Control and Indicators

Sample Port (Refer to Figure 2-9)

The sample port is used for checking CO

2 percentage in the

incubator chamber by an independent test instrument (such as

with a Fyrite, or similar CO2 test instrument).

To prevent CO2 loss, the sample port must be capped when it is

not in use.

CO2 Alarm (Refer to Figure 2-9)

The CO2 alarm is factory set to activate when the

chamber CO

2 content

deviates ± 5%. When a

CO2 alarm occurs, the

CO

2 Alarm indicator on

the control panel lights

and the audible alarm

sounds.

The CO2

alarm high and low set-

points are established

through the Watlow 93

CO2 controller (ALO,

and AHI). Refer to the

configuration record

included at the end of

Section 2.

2 - 5

Figure 2-7

Figure 2-8

Figure 2-9

Loading...

Loading...