5.5 Setting the Door Heater Control

High voltage is present behind the control panel.

Servicing must be performed only by qualified

electrical service personnel.

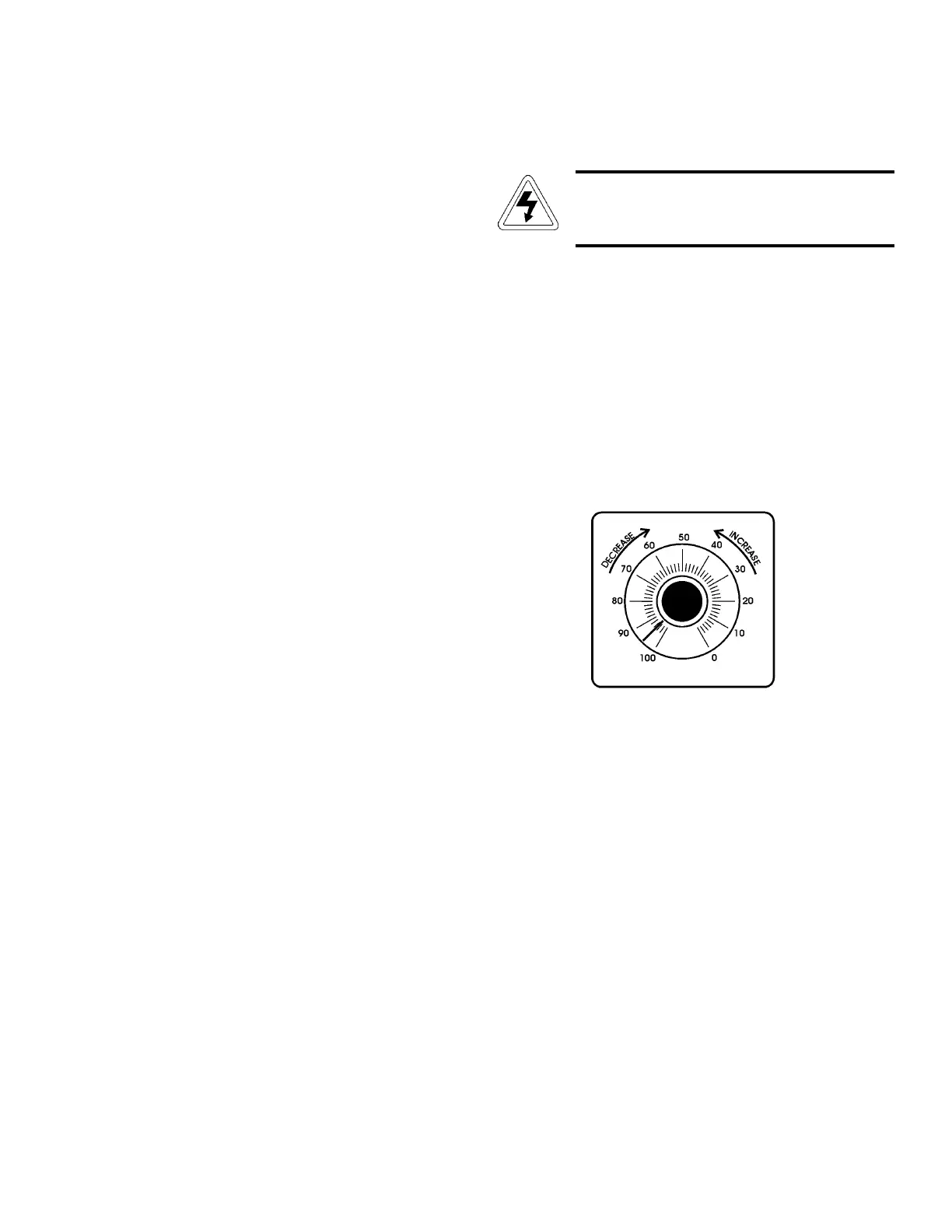

The infinite heater control is located in the right side of the

incubator top compartment behind the control panel door. The

heater varies the amount of door heat from no heat (zero) to full

heat (100) as indicated by the control dial face. If the knob is

turned past zero, a “click” will indicate that all power to the

door is shut off. If turned past 100, a similar “click” will indi-

cate that the heat is set at the maximum.

Initially, the units leave the factory with the dial set at 40.

If desired, the amount of heat can later be reduced until mois-

ture appears on the door, then the heat advanced. However, in

fluctuating ambient conditions, it is recommended that 40%

door heat be used.

8. Remove the nine 5/16” x 4” hex head bolts, lock wash-

ers, and two flat washers which secure the top assembly

to the cabinet. Note the washer arrangement on the

bolts.

9. Remove the black trim gasket located at the junction of

the top assembly and the main incubator section. The

ends of the gasket have been joined together at the rear

of the incubator.

Note: When raising the top section, note the orientation of the

gasket seal at the top opening of the incubator chamber. The

gasket must be correctly positioned when reinstalling the top on

the chamber.

10. Slowly lift the entire top assembly up and off the lower

chamber section while carefully guiding the capillaries

and sensing bulbs out of the chamber area. Place the top

assembly onto the carpenter’s horses or other support

arrangement.

11. Reinstall the top assembly by reversing the above proce-

dure. Exercise care particularly when:

• Placing and aligning the sealer gasket on the 1/2” flange

on top of the chamber when lowering the top in place.

• Routing the temperature and/or humidity sensors and

capillaries to prevent severely bending them.

• Mounting the temperature and/or humidity sensor bulbs

on the mounting brackets.

• Tightening the top mounting bolts alternately, to ensure a

balanced pressure on the gasket.

Model 3920 _______________________________________________________________________________Service

5 - 2

Figure 5-1

Loading...

Loading...