© Third Dimension Confidential Document D13-1604-OP-EN-3.3

V7.5

17

A

B

C

D

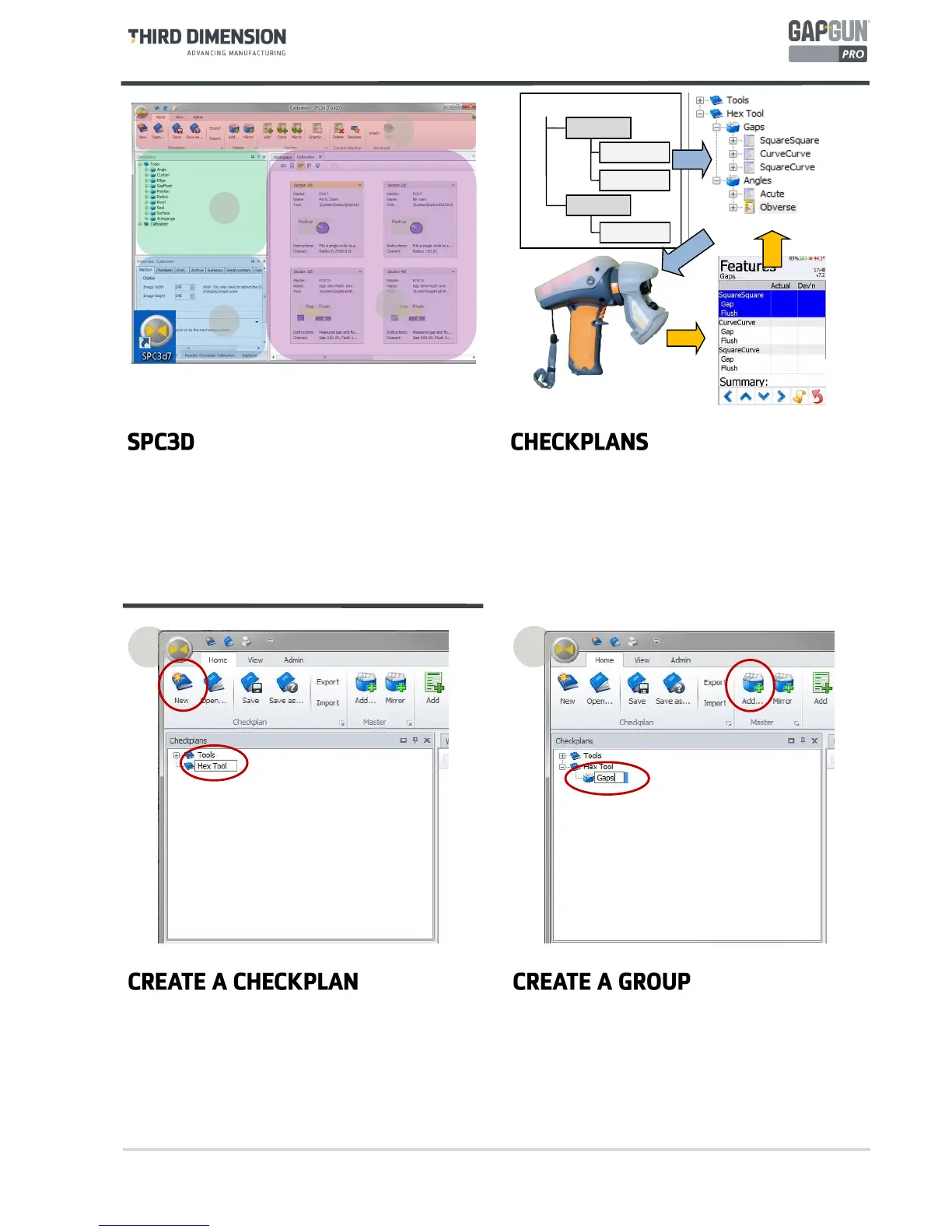

The SPC3D PC application is used to configure

Checkplans, collect measurements and configure

Features.

A. Context-sensitive command ribbon.

B. Checkplan tree view.

C. Tabbed Properties, Results and GapGuns windows.

D. Tabbed Workspace, Checkplan and Live display.

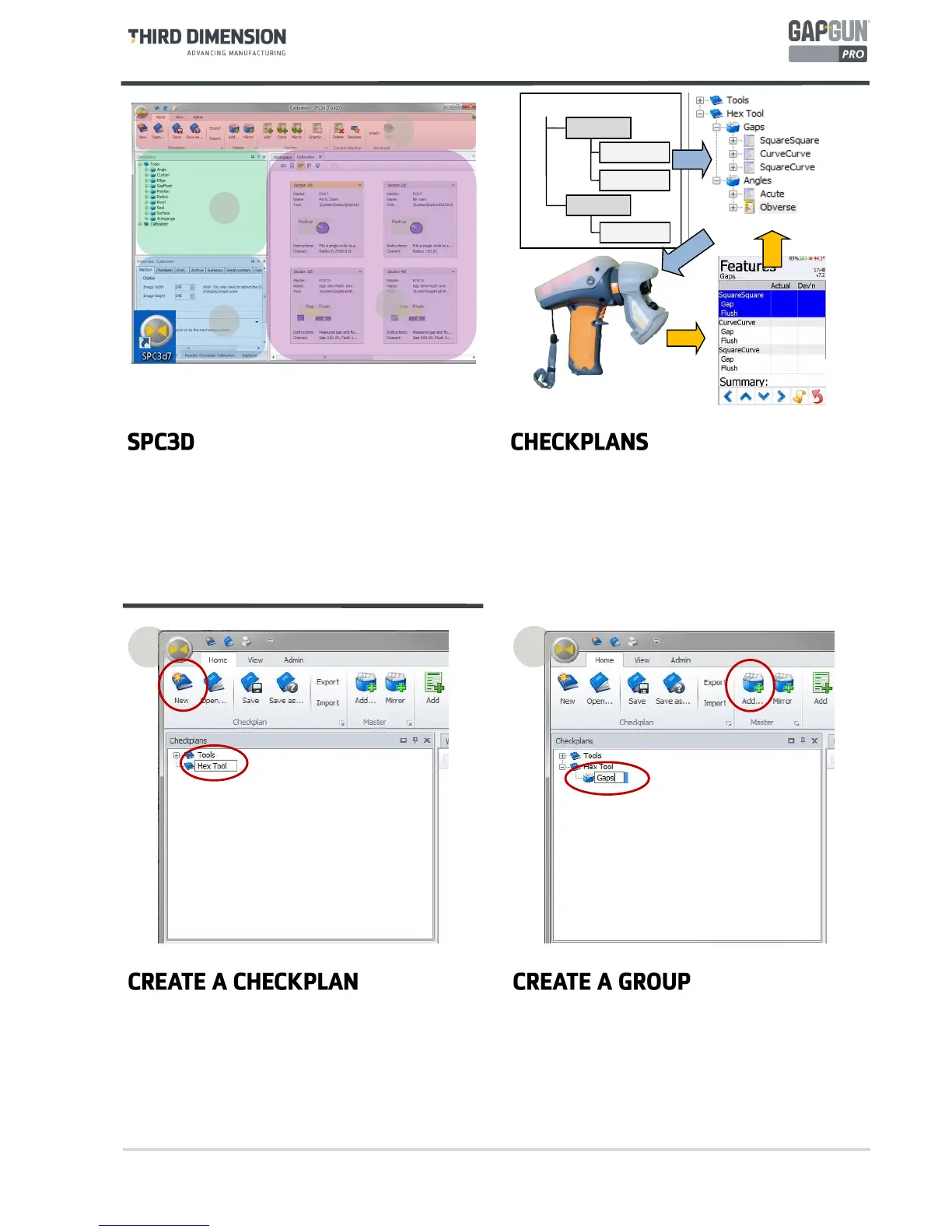

The GapGun uses a Checkplan to describe what

Features are to be measured and in what order.

Features can be put into Groups so that related

measurements can kept together.

The first step is to create a new Checkplan and give it a

descriptive name ‘Hex’.

A Checkplan can have one or more Groups, for example

grouping Features on one part of the object. A Group

can be copied to create repeating sets of Features or

mirrored to create a Group for the opposite side of the

object.

Add a Group to the Checkplan and give it a descriptive

name ‘Gaps’.

1

2

SPC3D is used to define the checkplan and configure the

features that are to be measured. These are combined

into a Works Order which is downloaded to the GapGun

to tell the operator what to measure and where to

measure each feature.

The measured results are then returned to SPC3D to be

stored and formatted for further processing.

Checkplan

Feature 1

Feature 2

Feature 3

Group 1

Group 2

Loading...

Loading...