This document is a manual for the Thunder Tiger PRO Series model aircraft engines. It covers various aspects from introduction and specifications to installation, operation, maintenance, and troubleshooting.

Function Description:

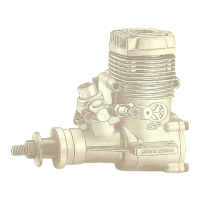

The Thunder Tiger PRO Series engines are miniature internal combustion engines designed for model aircraft. They are powerful, precision-made engines intended for both beginners and experienced flyers. These engines provide the thrust necessary to power remote-controlled airplanes.

Important Technical Specifications:

The manual provides a detailed specifications chart for several PRO Series engine models, including:

- PRO-36 (No.9130): Displacement 5.98 cc (0.365 cu.in), Bore 20.8 mm (0.819 in), Stroke 17.6 mm (0.693 in), Crankshaft Thread UNF 1/4-28, Practical RPM 2,000-17,000, Output 1.1 BHP/16,000 RPM, Weight (w/muffler) 313.6 g (11.06 oz). Recommended propellers for break-in/normal use are 10x5/10x6.

- PRO-40 (No.9140): Displacement 6.52 cc (0.398 cu.in), Bore 20.9 mm (0.823 in), Stroke 19.0 mm (0.748 in), Crankshaft Thread UNF 1/4-28, Practical RPM 2,000-17,000, Output 1.30 BHP/16,000 RPM, Weight (w/muffler) 454.5 g (16.03 oz). Recommended propellers for break-in/normal use are 10x6/10x6.

- PRO-46 (No.9141): Displacement 7.47 cc (0.456 cu.in), Bore 21.8 mm (0.858 in), Stroke 20.0 mm (0.787 in), Crankshaft Thread UNF 1/4-28, Practical RPM 2,000-17,000, Output 1.60 BHP/16,000 RPM, Weight (w/muffler) 448.5 g (15.82 oz). Recommended propellers for break-in/normal use are 10x6/10x7.

- PRO-61 (No.9160): Displacement 9.98 cc (0.609 cu.in), Bore 23.5 mm (0.925 in), Stroke 23.0 mm (0.906 in), Crankshaft Thread UNF 5/16-24, Practical RPM 2,000-17,000, Output 1.85 BHP/16,000 RPM, Weight (w/muffler) 758.4 g (26.75 oz). Recommended propellers for break-in/normal use are 11x6/11x7.

- PRO-91 (No.9190): Displacement 14.96 cc (0.913 cu.in), Bore 28.0 mm (1.102 in), Stroke 24.3 mm (0.957 in), Crankshaft Thread UNF 5/16-24, Practical RPM 2,000-16,000, Output 2.75 BHP/15,000 RPM, Weight (wo/muffler) 562.0 g (19.83 oz). Recommended propellers for break-in/normal use are 13x8/13x9.

- PRO-120 (No.9195): Displacement 20.76 cc (1.267 cu.in), Bore 31.0 mm (1.220 in), Stroke 27.5 mm (1.083 in), Crankshaft Thread UNF 5/16-24, Practical RPM 1,800-15,000, Output 3.2 BHP/14,000 RPM, Weight (w/muffler) 975.0 g (34.49 oz). Recommended propellers for break-in/normal use are 14x8/15x8.

- PRO-120RP (No.9196): Displacement 20.76 cc (1.267 cu.in), Bore 31.0 mm (1.220 in), Stroke 27.5 mm (1.083 in), Crankshaft Thread UNF 5/16-24, Practical RPM 1,800-15,000, Output 3.5 BHP/14,000 RPM, Weight (wo/muffler) 780 g (27.51 oz). Recommended propellers for break-in/normal use are 14x10/16x8.

All PRO series engines feature dual ball bearings, Schnuerle porting, a special ABN (Aluminum Piston, Brass Cylinder with Nickel Coating) type piston and cylinder sleeve, and automatic mixture control carburetors with a safe angular needle valve.

Usage Features:

- Installation: Engines can be mounted on rigid hardwood rails or metal/glass-filled nylon radial mounts. High-quality mounting hardware is essential. Flexible motor mounts can be used, but may slightly reduce performance.

- Radio Set-Up: Throttle servo linkage should be set to provide appropriate throttle arm action based on transmitter input (barrel open, open slightly, barrel closed).

- Fuel Tank: Position the fuel tank as close to the engine as possible, with its centerline level with the carburetor spray bar/needle valve assembly. The fuel tank system must be sealed to prevent fuel or air leakage. Wrapping the tank in foam rubber is recommended to reduce fuel foaming from vibration.

- Muffler/Silencer: Secure the muffler firmly with supplied bolts and lock washers. The rear half can be rotated to direct exhaust residue away. Regular checking and tightening of muffler bolts are advised.

- Fuel and Pressure Lines: Use a knife or razor blade to cut silicone tubing for fuel and pressure lines. Connect the fuel tank fill line to the carburetor and the vent line to the muffler's pressure fitting.

- Glow Plug: Use a 4-way wrench to install the glow plug with a washer between the cylinder head and plug to prevent gas leakage. Do not overtighten. Thunder Tiger .10-.61 size engines perform best with a "hot" long-type plug (e.g., K&B or O.S. No. 8).

- Propeller: Fix the propeller and spinner firmly. Turn the propeller clockwise until resistance is felt at TDC, then set blades at 2 and 8 o'clock positions, and tighten the nut with a 4-way wrench. Propeller balance is critical; an unbalanced propeller can cause significant damage. Wood propellers are preferred over some nylon types due to strength.

- Break-In/Run-In Procedures: A prolonged break-in period is not necessary due to the ABN construction. After one tank on the ground, the engine can be flown. Bench-running on a test stand is an option, but never use a vise.

- Fuel Selection: A fuel containing 20% castor/synthetic blend with no more than 10% nitromethane is recommended for break-in. Avoid fuels with only synthetic lubricants during initial break-in. For general use, 25% lubricant and 75% methanol is recommended. For more power, 5%-15% nitromethane and 20% lubricant can be used. If using only synthetic lubricant, a slightly richer needle valve setting is advised to extend engine life. Never use fuel with less than 20% lubricant.

- Starting:

- Pre-Adjust Needle Valve: Close the needle valve clockwise until resistance is felt, then open it 2 to 2.5 turns counter-clockwise as a starting point.

- Choking/Priming: Open the throttle to 1/2-3/4. Cover the carburetor opening with a finger (without glow plug battery connected) and rotate the propeller 2-3 turns until fuel flows into the carburetor. More fuel is needed for the first start or when cold.

- Heating the Glow Plug: Connect a glo-starter or 1.5V ignition battery to heat the glow plug. The platinum alloy coil keeps the engine running after the external power is removed.

- Flipping Propeller: Open the throttle 1/4 to 1/2. Flip the propeller with a "chicken-stick" or use an electric starter. The engine should fire after a few flips. Always have a helper hold the aircraft.

- Fine-Tuning:

- Needle Valve Adjustment (Break-In): After starting, advance throttle to full open. Lean (clockwise) the needle valve gradually until RPM increases. Remove the glo-starter. If the engine stops, lean slightly more and restart.

- Needle Valve Adjustment (After Break-In): With the airplane held, advance throttle to full open. Slowly lean the needle setting until RPM slows, then richen to achieve maximum RPM. Richen slightly further until a slight RPM decrease is heard.

- Idle Mixture Adjustment: Located inside the throttle barrel. To determine if the idle mixture is too rich or lean:

- Method A: Close throttle to lowest running position. Disconnect fuel tubing. If engine speeds up before quitting, it's too rich. If it slows and quits, it's too lean.

- Method B: Close throttle below stable idle. If engine hesitates before speeding up, it's too rich (lots of smoke). If it stops abruptly when throttle is opened, it's too lean.

- Adjust by turning the idle mixture adjustment screw about 30° clockwise for rich, or 30° counter-clockwise for lean. Never adjust more than 30° at a time or more than one full turn total.

- Stopping: Cut off fuel supply by pinching the fuel line or disconnecting it. Alternatively, use the radio control system by moving the throttle trim lever below the idle position.

Maintenance Features:

- Post-Flight Care: Model fuel contains alcohol, which attracts moisture and can cause corrosion. After each flying session, run all fuel out by disconnecting the fuel line from the carburetor. If storing the engine for a while, put 4-5 drops of after-run oil (e.g., Marvel Mystery Oil, Prather, Pacer) into the carburetor and glow plug hole. Wrap the engine in a soft cloth and store in a sealed plastic bag.

- Cleaning: Keep the outside of the engine clean. Use clean, fresh fuel and ensure the fuel can, pump, and fueling system are free from dirt particles. Install a fresh fuel filter between the fuel tank and carburetor, and between the fuel pump and filling line.

- Disassembly: Avoid unnecessary disassembly as it can upset precision fits. If complete cleaning is needed (e.g., after a crash), only remove the carb (do not disassemble), muffler, backplate, and cylinder head. Flush with fresh fuel and reassemble. Apply after-run oil. Further disassembly may void the warranty.

- Overheating Prevention: Excessive heat reduces engine life. Lubricants remove heat as exhaust vapor. Periodically remove the muffler and visually inspect the exhaust port and piston. A very dark stain on the piston indicates overheating, possibly due to a lean needle setting or lack of airflow.

- Cowling Airflow: For enclosed cowlings, ensure proper airflow. A general rule is to have twice the exit area as the inlet area (e.g., 4 sq. in. inlet needs 8 sq. in. exit). This is especially critical with synthetic lubricant fuels.

Warranty:

The engine comes with a 3-year warranty to the original purchaser, covering defects in materials and workmanship, provided it is returned with proof of purchase. Crash damage, improper use, customer disassembly, use of improper fuel or accessories (propellers, glow plugs), or use outside its intended purpose will void the warranty.

Service Procedures:

For service, do not return the engine to the place of purchase. Remove the engine from the model. Enclose a complete written explanation of the problem, proof of purchase, name, address, and daytime telephone number. For non-warranty repairs, charges will be billed C.O.D., with estimates available upon request. U.S. and Canadian customers should send their engine via insured mail or UPS to ACE HOBBY DISTRIBUTORS, INC. at 26021 Commercentre Dr., Lake Forest, CA 92630-8853, U.S.A. International customers should contact their authorized Thunder Tiger agent.