3

TX, 100, 200 SERIES INSTALLATION

CANOPY ASSEMBLY

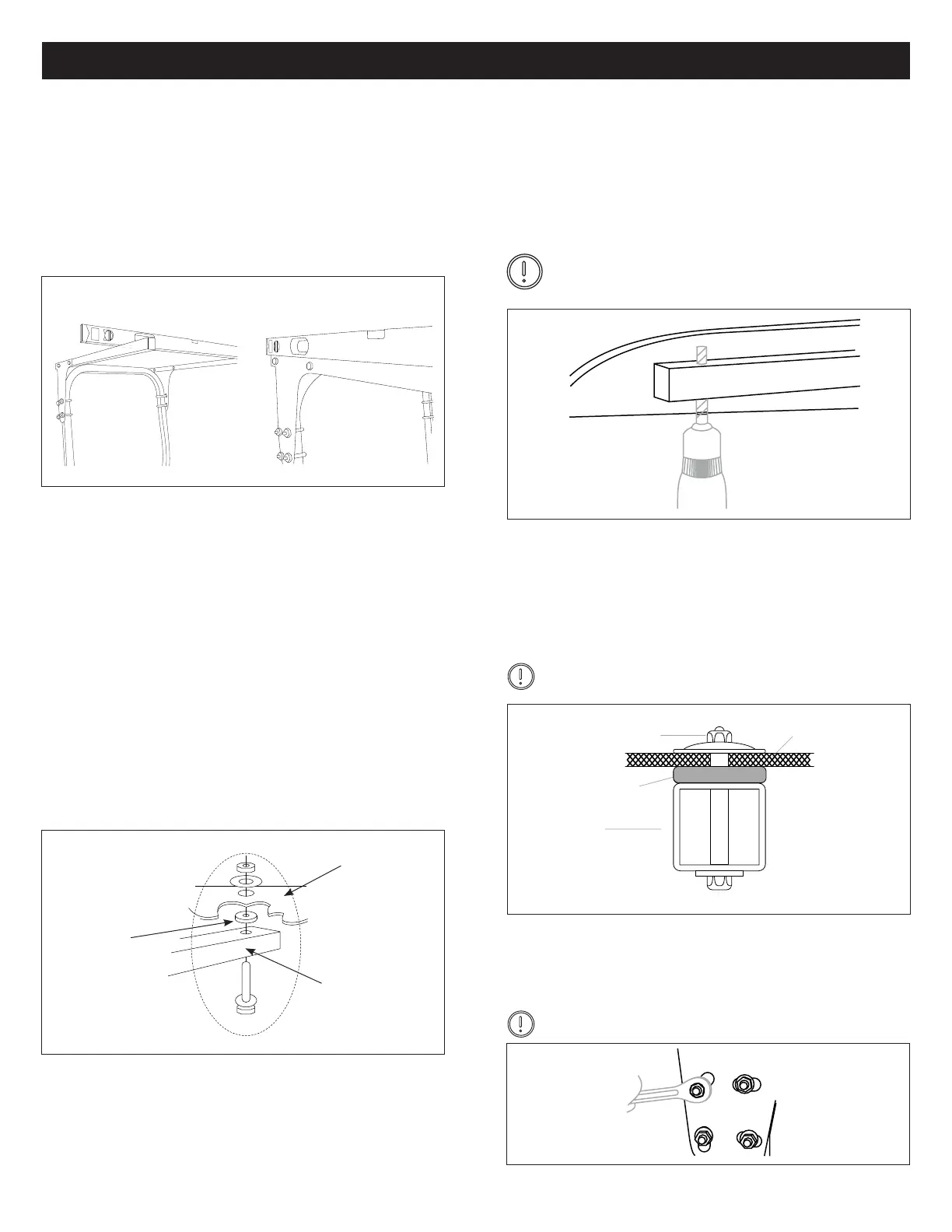

Level the Brackets1.

The bracket assembly should be mounted level.

(See Figure 1)

Figure 1

Once level - Securely tighten the (8) eight ½” ange nut (B).

• Even with the top of the roll bar

• Side to side in front and rear

• Parallel to tractor frame

Figure 3

Place sunshade onto mounting brackets. Proper

placement should be:

• Fore-Aft positioning: The inside rear of the canopy

should sit within 2-3” of the end of the mounting

tubes.

• Left-Right: The canopy rest on the at mounting

pads integrated into the canopy design, and be equal

distance from the mounting tube.

Center the Canopy2.

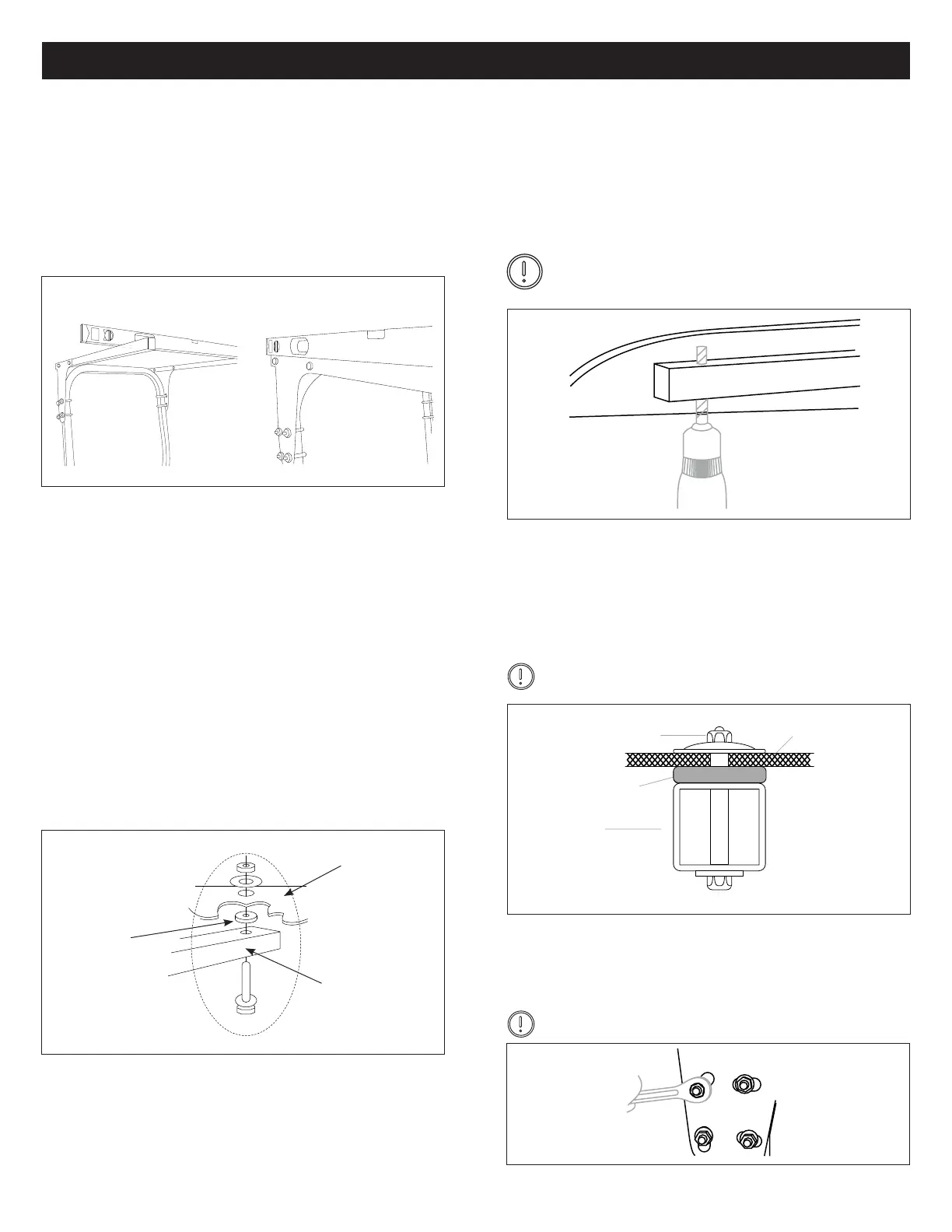

Place rubber isolation pads on top of canopy support

tube, in alignment with mounting holes in tubes. (See

Figure 2)

Figure 2

Figure 5

Fiberglass

Canopy

Rubber

Isolation Pad

Steel Tube

Add Isolation Pads

Drill and Mount

3.

4.

Tighten Brackets6.

• Starting in either rear corner using the 3/8” hole in the

mounting bracket as a guide, drill from the bottom of

the canopy upward.

• Insert and assembly canopy mounting hardware

• Repeat for remaining three corners.

Before drilling and carefully centering canopy,

visually inspect all four mounting points to assure

proper location on mounting pads. (See Figure 3)

Figure 4

Tighten Mounting Hardware5.

NYLOCK NUT

RUBBER

ISOLATOR

PAD

SIDE RAIL

CANOPY

Tighten the canopy mounting hardware

DO NOT OVER-TIGHTEN!

The mounts are designed to allow the canopy to “oat” in

rubber. Tighten to a slight “bulge” in the 1/2” rubber isola-

tor pad (G). (See Figure 4)

Tighten the mounting bracket assembly and you’re done!

(See Figure 5)

DO NOT OVER-TIGHTEN!

Loading...

Loading...