6

SERVICE HINTS

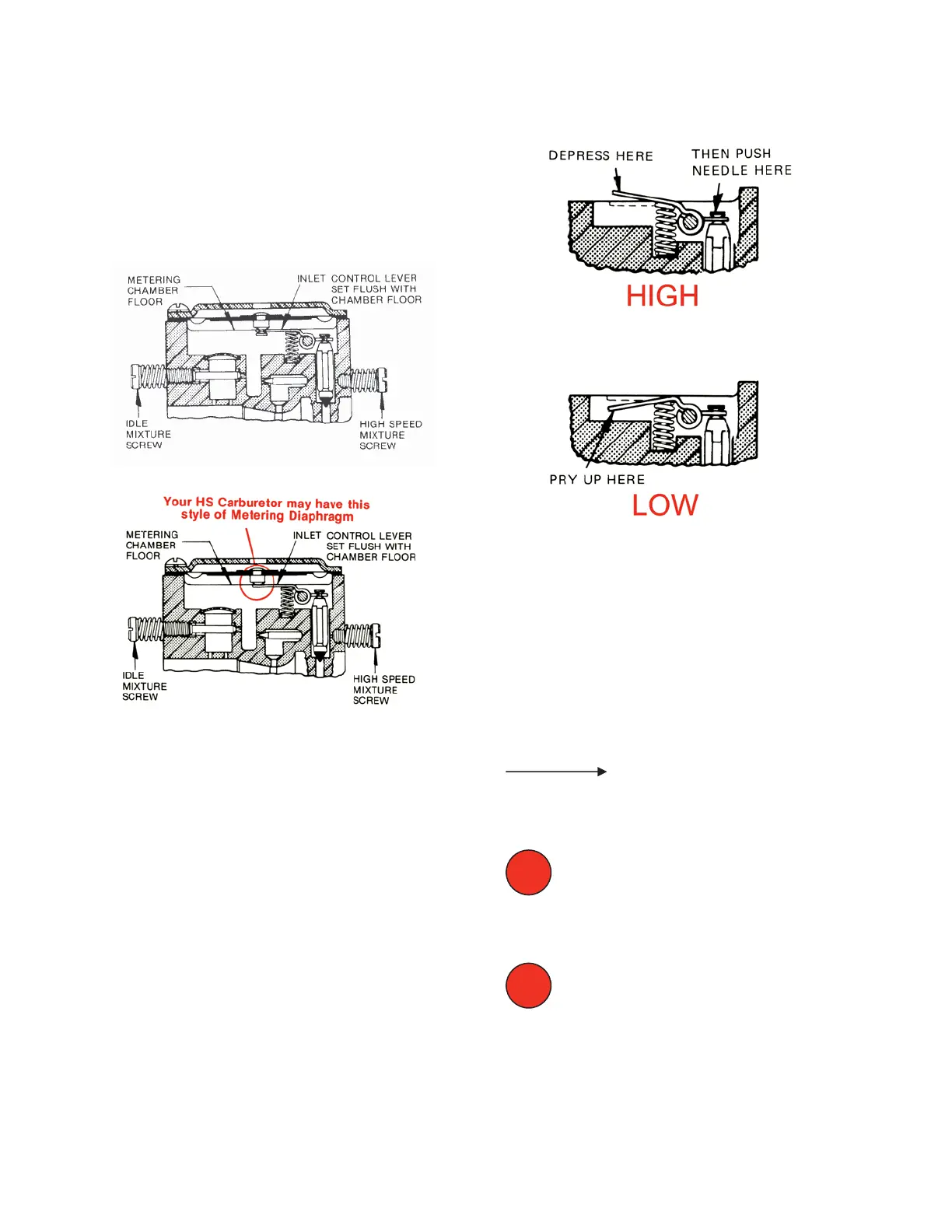

Be certain both diaphragms are installed correctly -

the

pump diaphragm next to the metering body, then the

gasket – the main diaphragm gasket, then the main

diaphragm. Evenly tighten all screws to insure

complete

seal.

When reassembling the inlet control lever and spring,

care should be taken to see that the spring rests in

the well of the metering body and locates on the

dimple of the inlet control lever (as illustrated above).

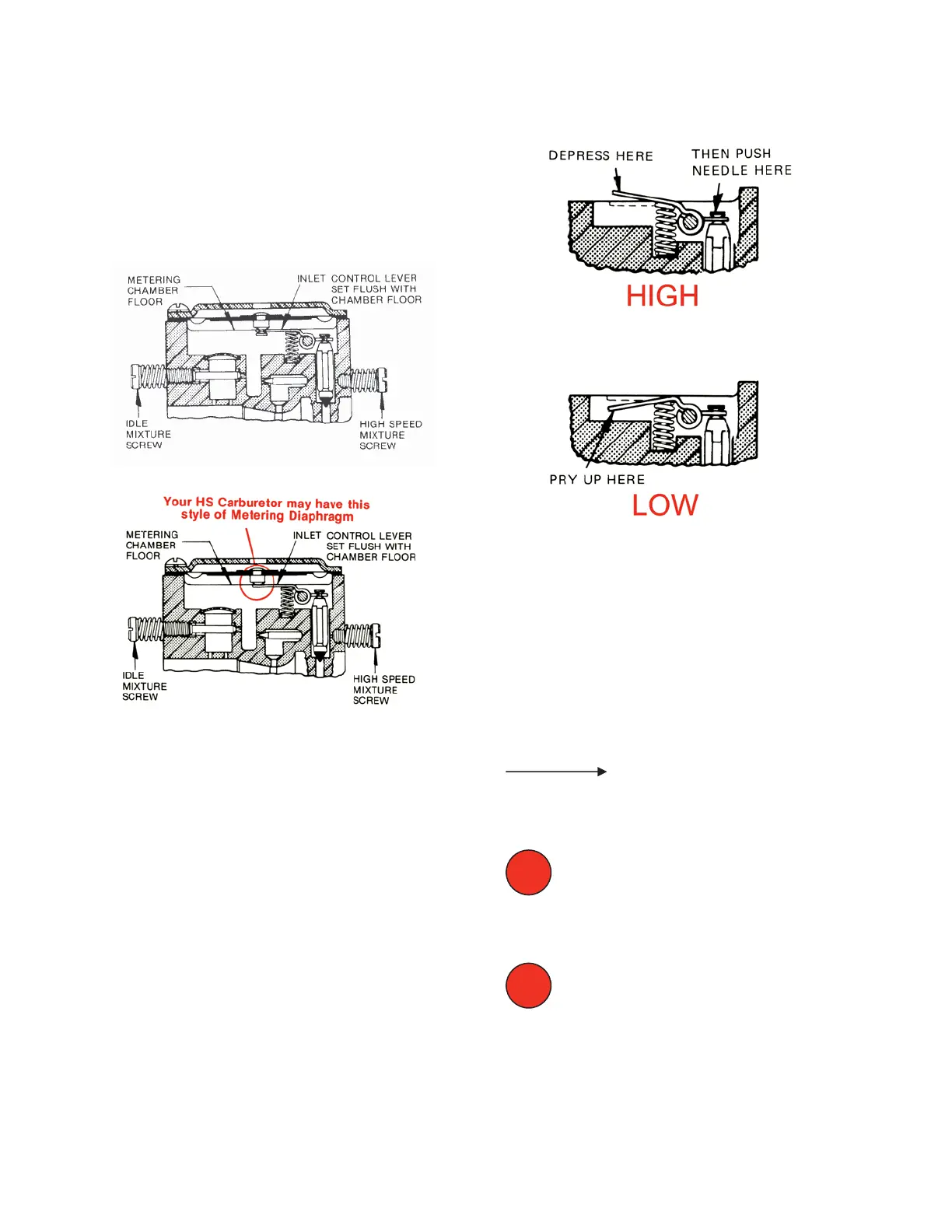

CAUTION: Do not stretch spring. Inlet control lever is

properly set when flush with the floor of the

diaphragm chamber. If diaphragm end of control

lever is low, pry up. If lever is high, depress

diaphragm end and push on needle for proper

adjustment. (See illustration). On some models the

inlet control lever is hooked to both the inlet needle at

one end and the metering diaphragm at the other. On

other models the inlet lever is hooked to the inlet

needle while the opposite end of the lever merely

rests against the metering diaphragm. Special care is

required when reassembling these parts to insure

proper operation.

CAUTION:

Under extreme conditions of

clogged idle fuel channel and discharge ports, it may

be necessary to remove the channel welch plug. If

so, it must be done very carefully in the following

manner:

Drill a 1/8 “ diameter hole through the

11/32” diameter welch plug. This hole

should just break through the welch plug.

Deeper drilling will seriously damage the

body casting and render the carburetor

non-serviceable.

Carefully pry out the welch plug and

clean discharge ports and cross

channels. To reinstall, place welch

plug in well, convex side up, and flatten

with a flat end tool slightly larger than

the welch plug. Nozzle welch plug can

be removed in the same manner by

using a 1/16” drill.

SERVICE DATA

2

1

Loading...

Loading...