Injection Molding Machine Chapter 5

V3.0

5-1

Chapter 5: Trouble Shooting

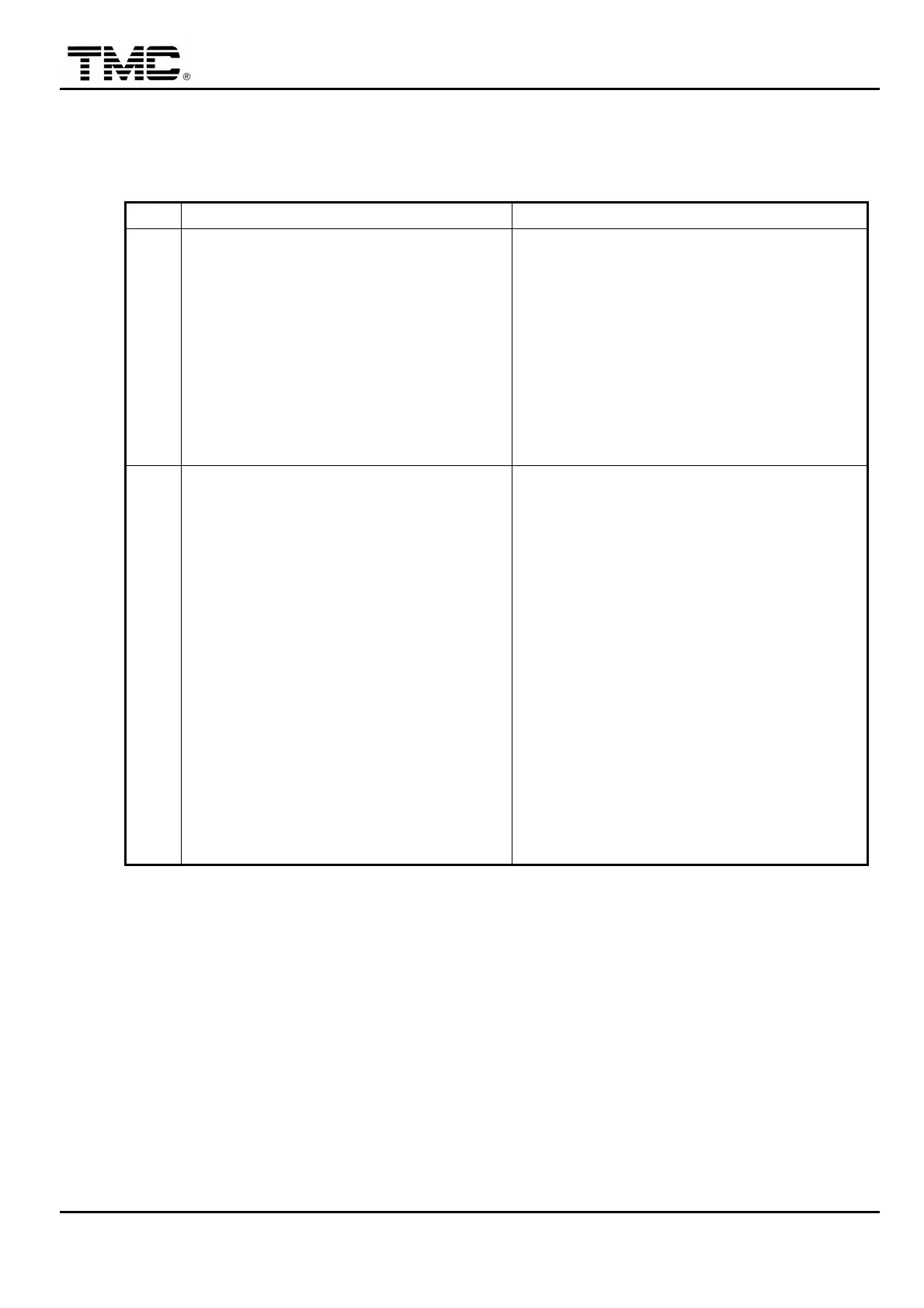

1. Mechanical Part

Item Possible Causes Solution

1.1 Motor can not be started

A Power not being turned on

B Front or rear emergency switch is

pressed.

C Over-load relay tripped.

D Poor signal transmission

E Fuse blown out

F I/O W (6A) fuse blown out

A Turn power on

B Rotate emergency stop button to release

lock

C Reset overload relay

D Turn on system self diagnosis function to

check whether or not various modules (PC

boards) are normal (O)

E Replace fuse

F Replace fuse

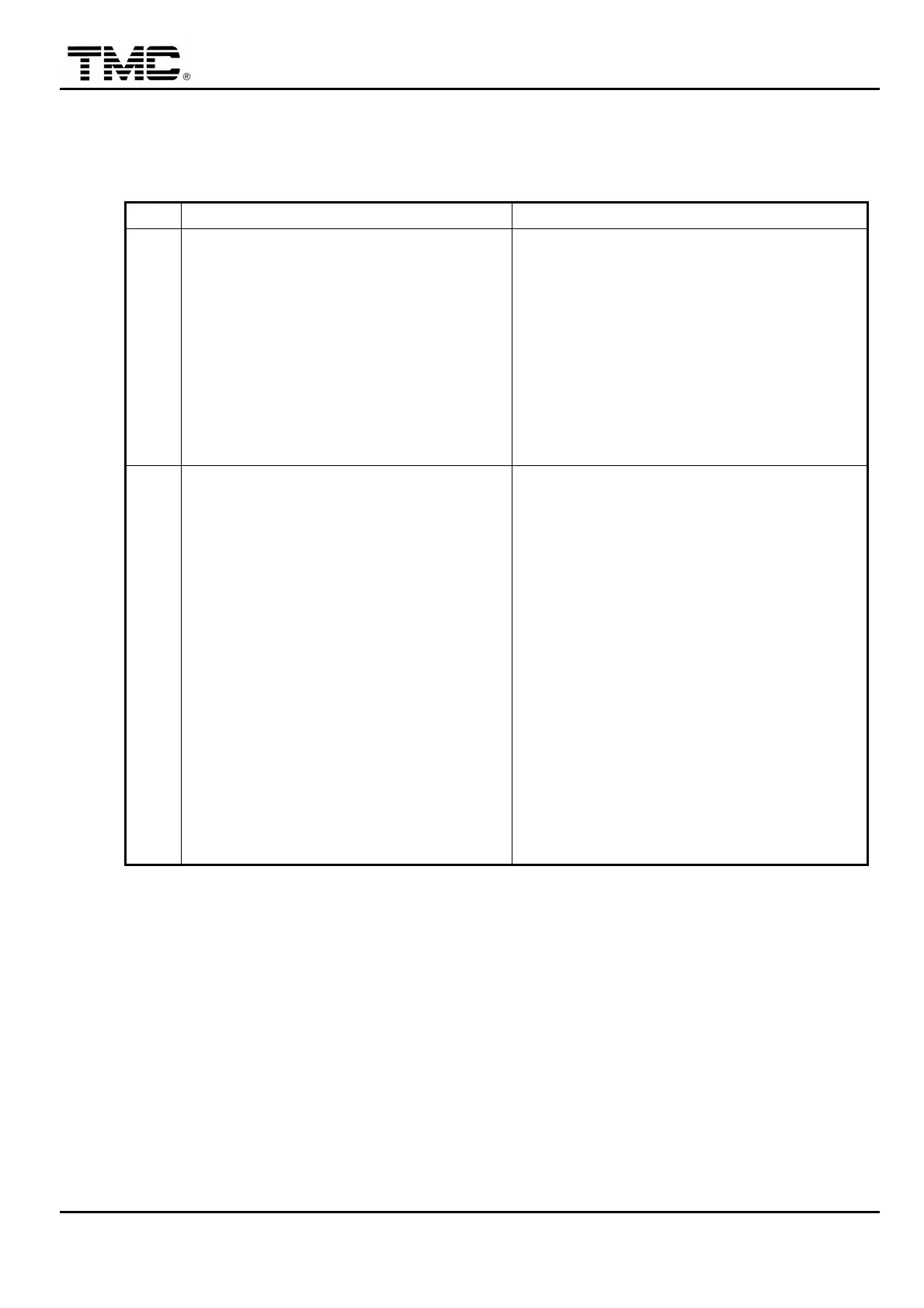

1.2

No clamp close

A Safety gate isn’t closed properly

B Robot enable clamp close signal isn’t

on

C I/O W (6A) fuse blown out

D In manual mode, core in not

completed

E Corepull operation not completed

F Ejector retract not completed

G Directional valve stuck

H Directional valve signal wire failure

I Decompression circuit failure

J Clamp close pressure too low

K Clamp close back pressure time too

short

A Check I/O 101, 103, 109, 110 must be

on

B Check robot circuit, I/O 222 must be on

C Replace fuse

D Manually operate corepull in until

operation is completed.

E Check corepull setting conditions

F Check ejector set position

G Clean direction valveV6, V7, manually

operate spool

H Repair signal line 156/0, 157/0 andV35

I check V10 or rotate F8 clockwise to

tighten it up

J Set clamp close pressure 60~80Bar

K Set clamp close back pressure time

0.2~0.5

Loading...

Loading...