Injection Molding Machine Chapter 5

V3.0

5-2

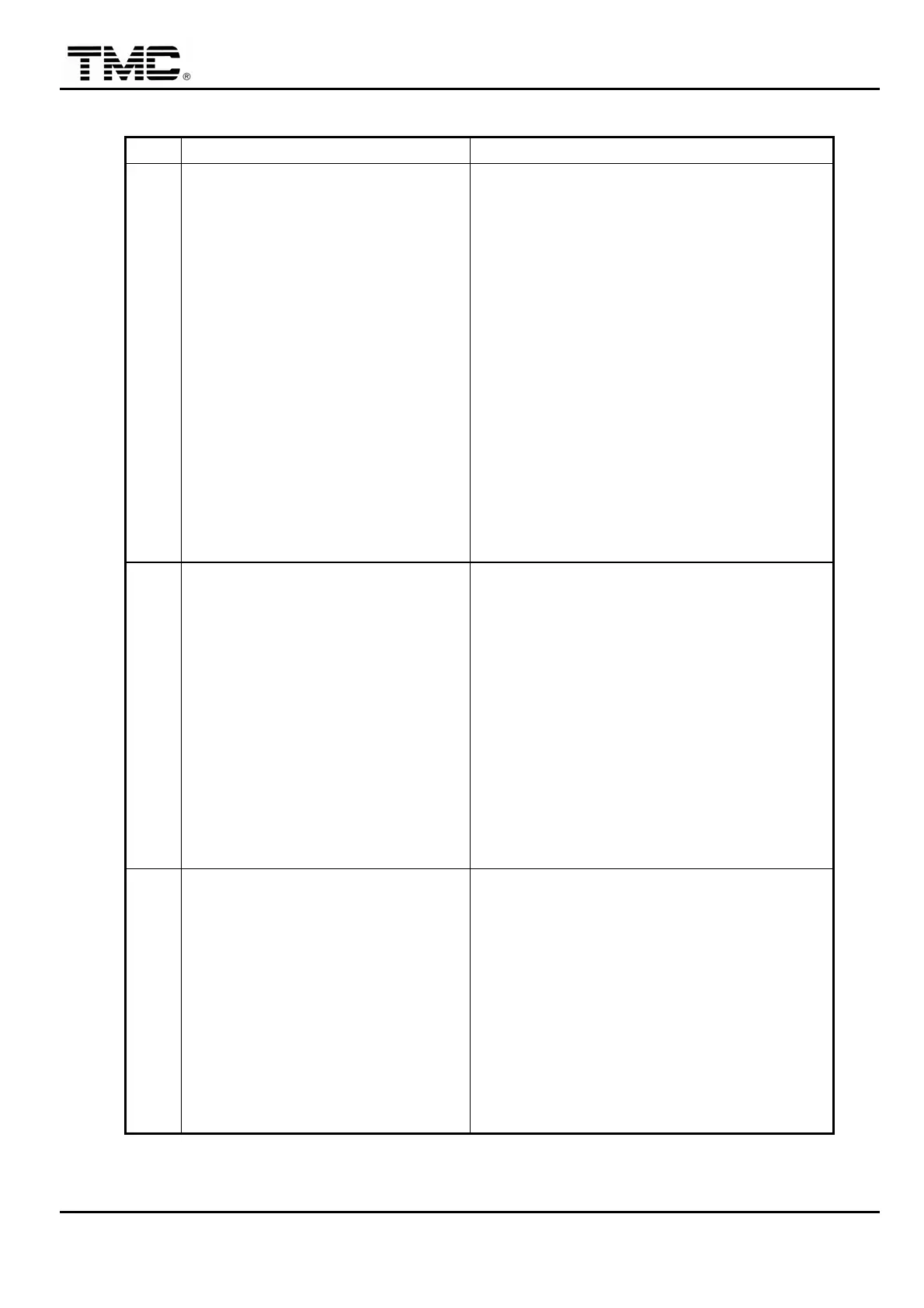

Item Possible Causes Solution

1.3

No clamp open

A Clamp open stop position

improper

B In manual mode, corepull out

not completed

C Corepull operation not completed

D Decompression circuit failure

E Clamp locked time too long

F Directional valve stuck

G Directional valve signal wire

failure

H Mold stuck, can not be opened

I Speed setting too small

J Pressure is insufficient

A Set clamp open stop position

B Manually operates corepull out until

operation is completed.

C Check corepull setting condition

D CheckV8, F8 or set fast speed to slow

speed position to 0

E Contact maintenance department of TMC

agent.

F Clean direction valve V8, V9, V10

G Repair signal wire156/0, 157/0 andV35

H Repair mold

I Increase speed setting

J Increase pressure setting

1.4

Ejector advance failure

A Clamp not fully opened

B Eject pressure, speed not being

set properly

C Eject has reached to set position

D Mold stuck, ejector plate can not

move advance

E Directional valve stuck

F Directional valve signal wire

failure

G Ejector plate hole position not

conform to the mold

A Open clamp again or adjust clamp open

stop position

B Adjust set value

C Adjust set value

D Repair mold

E Clean direction valve V26, manually press

SPOOL

F Repair signal wire 176/0

G Confirm ejector hole position of the mold.

1.5

Ejector retract failure

A Ejector pressure, speed are not

set properly

B Ejector retract has reached set

position

C Mold stuck, ejector pin can not

be pulled back

D Direction valve stuck

E Direction valve signal wire failure

A Adjust set value

B Adjust set value

C Repair mold

D Clean direction valve V27, manually press

spool

E Repair signal wire 177/0

Loading...

Loading...