Injection Molding Machine Chapter 5

V3.0

5-3

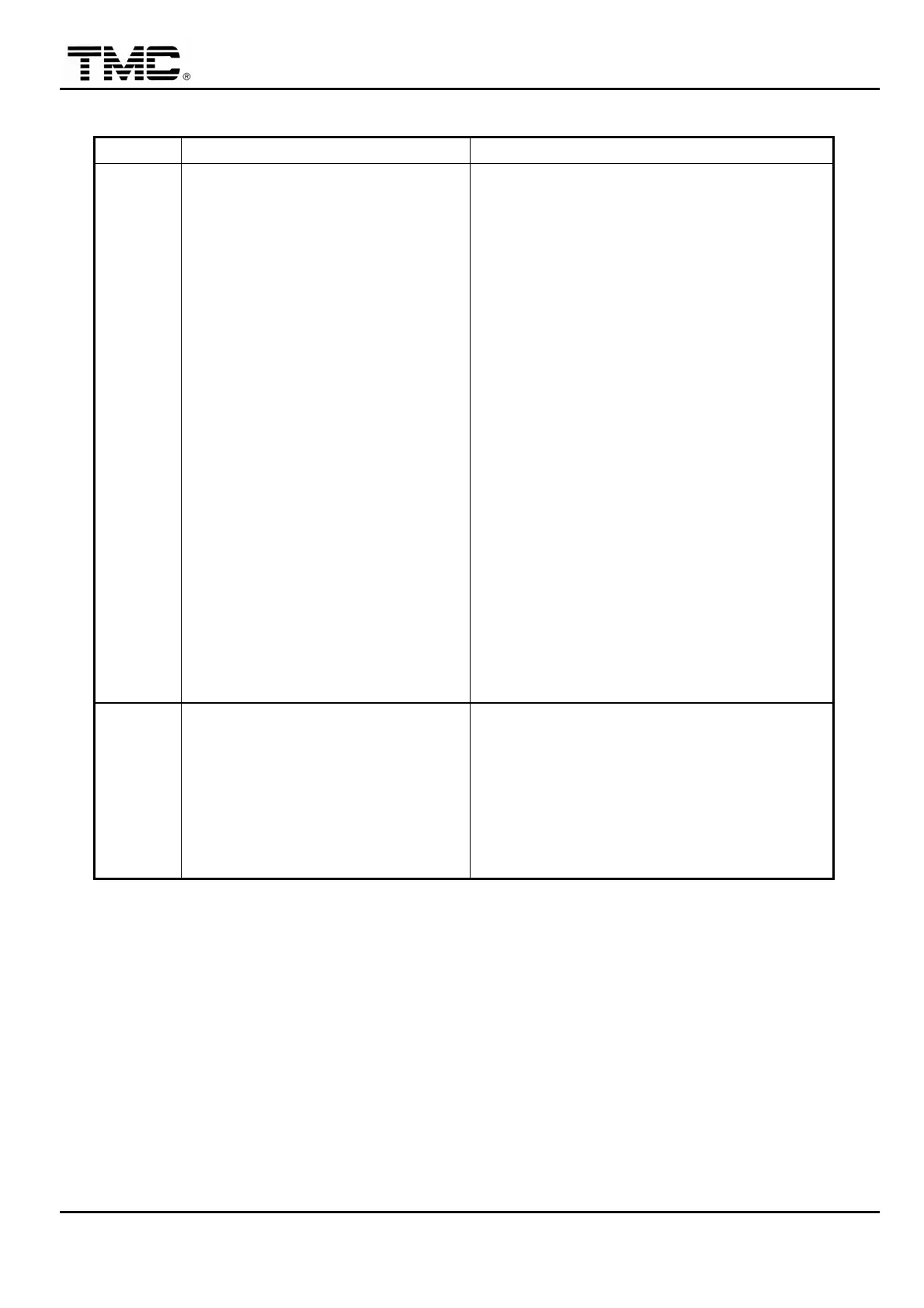

Item Possible Causes Solution

1.6

No injection

A Temperature condition not ready

B Carriage doesn’t advance to end

point

C I/O W (5A) fuse blown out

D Injection delay time is set too long

E During auto clamp close, carriage

in not reach to end position

F Suck back logic valve stuck and

failure

G Back pressure valve improperly

adjusted or failure

H Directional valve stuck

I Directional valve signal wire

failure

J Injection parameter not set

properly

K Material not melt

L Injection piston loose

M Nozzle blocked or screw tip

assembly damaged

N Check valve or screw worn out

O No material in the barrel

P Carbonized material in barrel.

A Check temperature setting page

B Adjust parameter setting

C Replace fuse

D Adjust parameter setting

E Check clamp close and carriage in operation

F Clean L17,C16,V17

G Clean and repair R6

H Clean direction valveV11,V17, manually

press SPOOL

I Repair signal wire261/0, 267/0

J Adjust injection parameter

K Adjust temperature parameter

L Repair injection cylinder

M Remove nozzle or screw and cleaning

N Replace with new part

O Check hopper, barrel feed throat

P Remove screw for cleaning

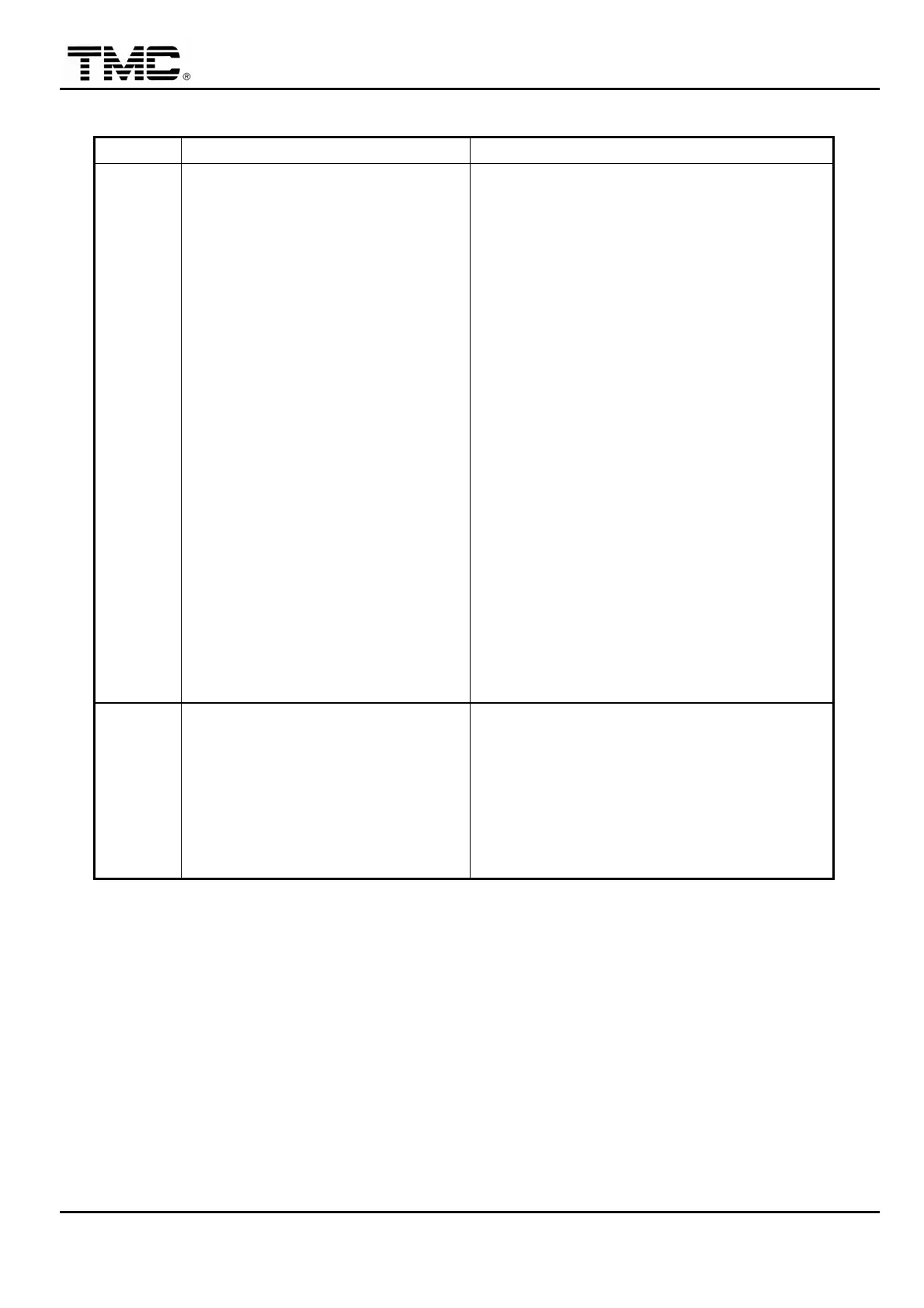

1.7

No suck back

A Temperature condition not ready

B Position, pressure, speed, time

are not set properly

C Directional valve stuck

D Directional signal wire failure

E Screw connecting semi-circle ring

loose

A Check temperature setting page

B Adjust parameter setting

C Clean L17, V17, V17-1, manually press

spool

D Repair signal wire 261/0, 267/0

E Repair locking semi-circle ring.

Loading...

Loading...