Injection Molding Machine Chapter 5

V3.0

5-4

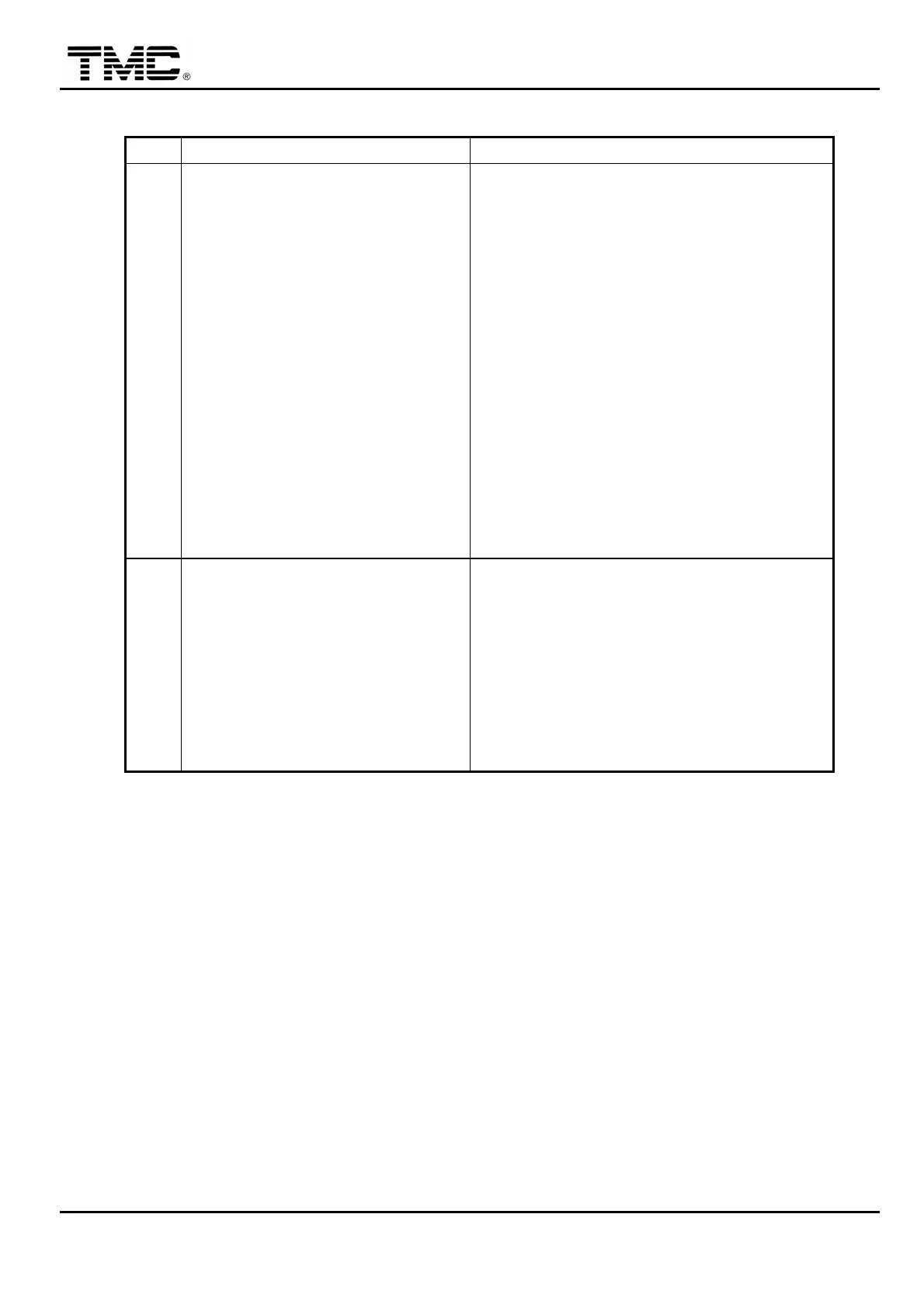

item Possible causes Solution

1.8

No charge

A Temperature condition not ready

B Charge position , pressure ,

speed, time are not set properly

C Barrel temperature insufficient

D Charging delay time is set too long

E Pre-suck back function is on.

F Charge back pressure too high

G No material in the barrel.

H Carbonized material in the barrel.

I Resin temperature too high or

gasified.

J Screw check valve worn out

K Directional valve stuck

L Directional valve signal wire

failure

M Hydraulic motor torque

insufficient

N Quill damaged

A Check temperature setting page

B Adjust parameter setting

C Check temperature control system

D Adjust parameter setting

E Revise function setting

F Lower down back pressure setting

G Check hopper, barrel feeding port

H Remove barrel for cleaning

I Clean barrel

J Replace screw tip assembly.

K Clean and repairV16, V16-1

L Repair signal wire 266/0

M Increase pressure or replace hydraulic motor

N Add grease, replace bearing, key, quill.

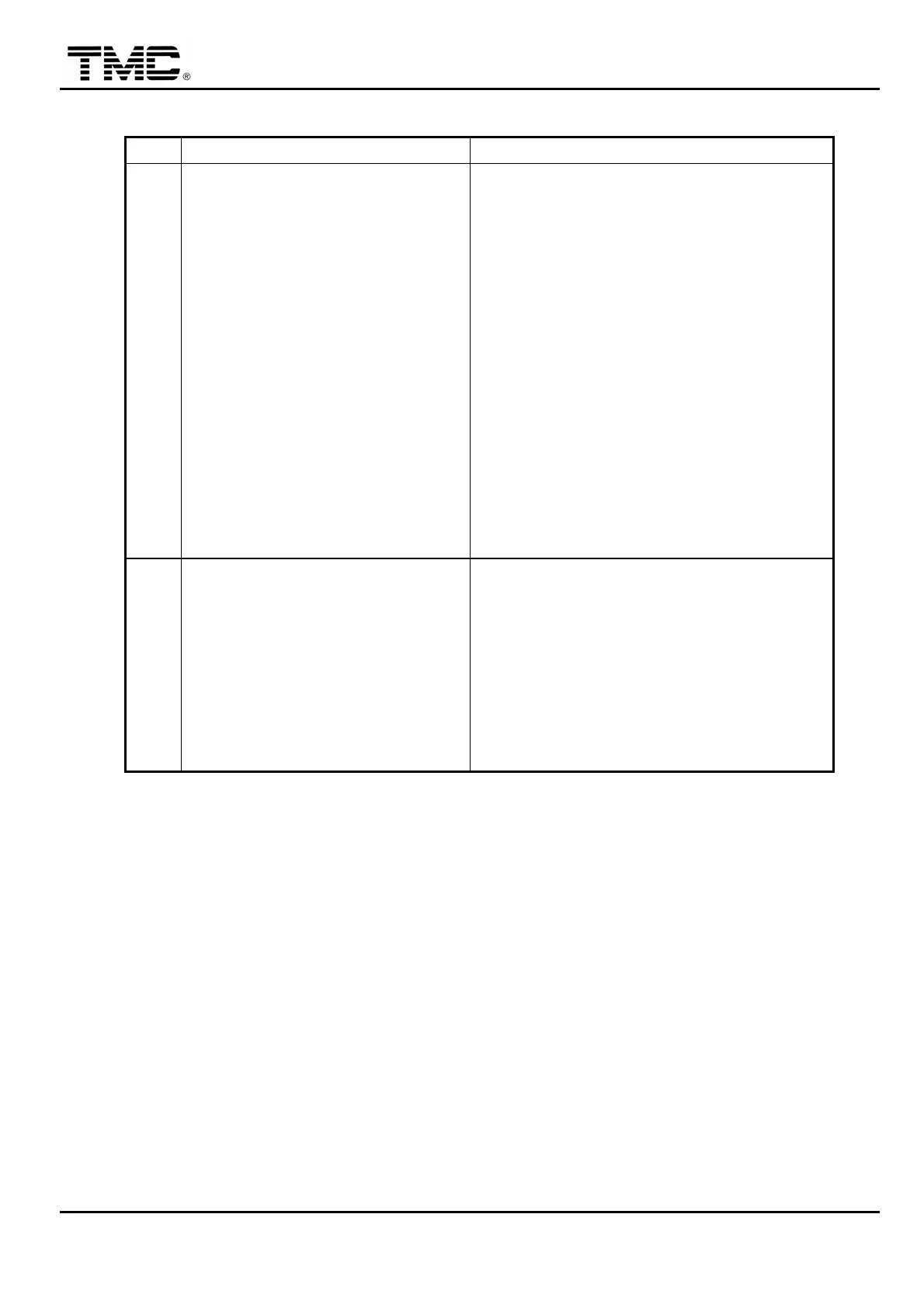

1.9

No carriage adv. / ret.

A Position, pressure, speed are not

set properly

B Directional valve stuck

C Directional valve signal wire

failure

A Adjust parameter setting

B Clean V21, V22, manually press spool

C Repair signal wire 271/0, 272/0

Loading...

Loading...