Injection Molding Machine Chapter 5

V3.0

5-6

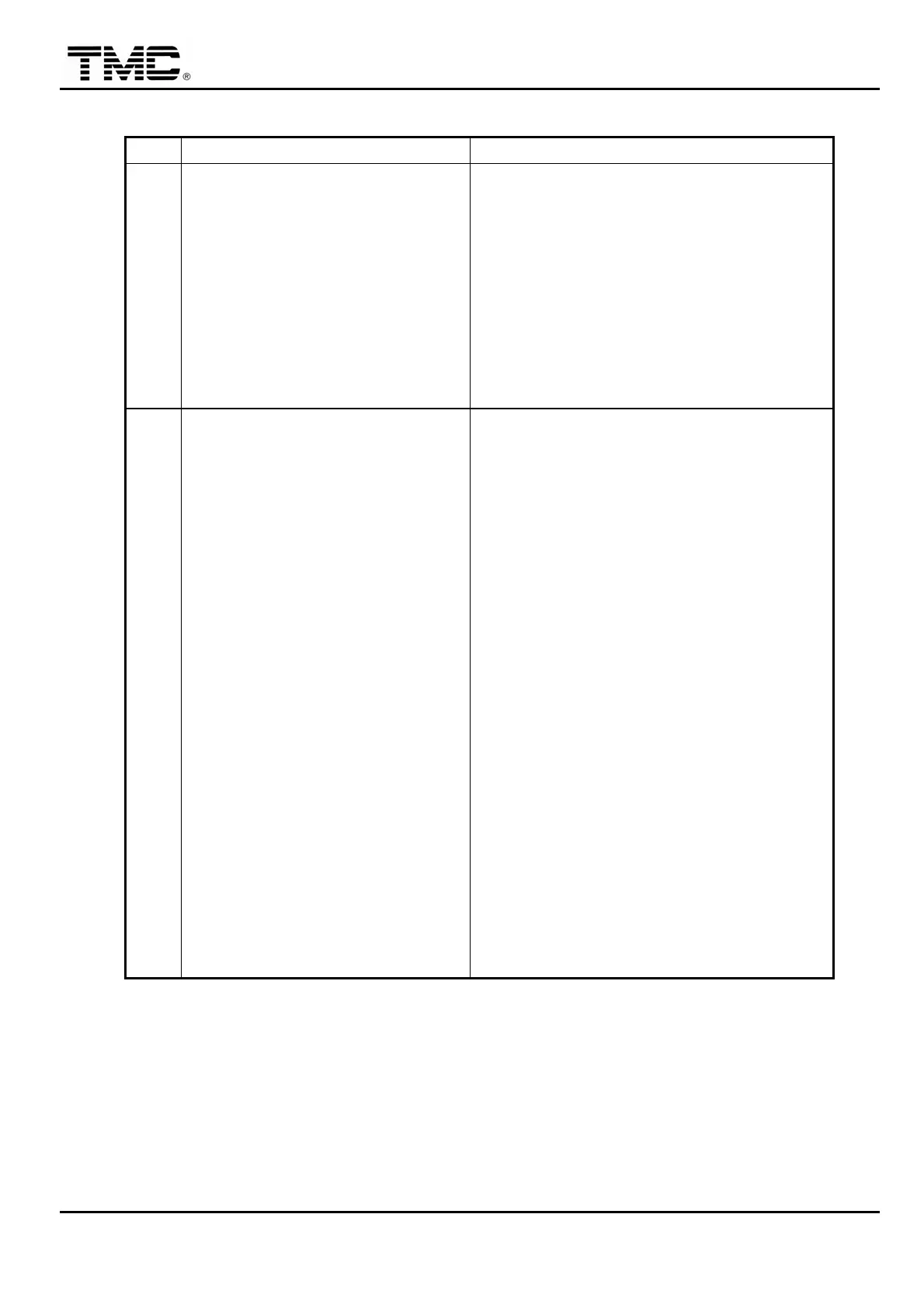

Item Possible Causes Solution

1.12

Corepull failure

A Clamp open and close not in

position

B Mold stuck

C Hydraulic piping not conform to

actuation sequence

D Actuation conditions are not

satisfied.

E Improper setting of corepull

position, pressure, speed.

F Directional valve stuck

G Directional valve circuit failure

A Correct clamp open, close and corepull

position

B Check and repair mold

C Check and repair pipeline and operation

sequence

D Perform clamp open/close operation first

E Correct setting value

F Clean V31, V32 manually press spool

G Check and repair signal wires 181/0, 182/0

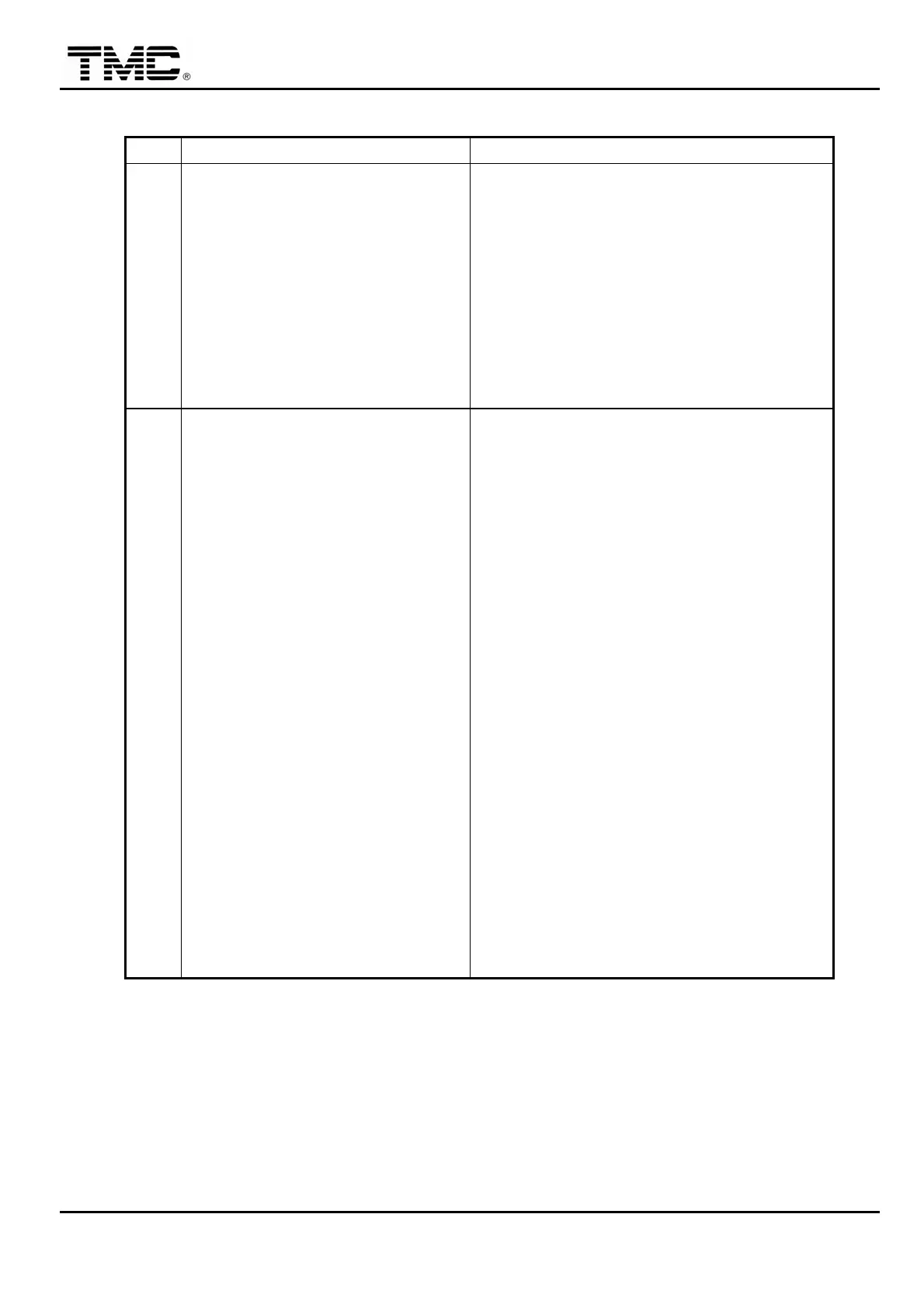

1.13

Temperature control abnormal

A Heater switch is not turned on

B Cold starting protection time in

action

C Temperature doesn’t reach the

range of setting value within –5

degree when starting machine first

time.

D Heater band failure

E Heater contactor M4 damaged

F Temperature in control box

indicates –17 degrees

G Temperature unstable

H Temperature board TMP LED light

not flicker

I Temperature keeping function is

on

J “LO” temperature too low

K “HI” temperature too high

L “ABN” heating circuit failure

M “DIS” thermocouple broken

N “INV” thermocouple polarity

wrongly connected.

A Turn heater switch on

B Wait for completion of time

C Wait for temperature rising or correct setting

value

D Check and repair heater band

E Check and replace contactor

F Poor connection of +20, C in signal transfer

board

G Check thermocouple wire or replace TMP

temperature board

H Check the power of switching power supply

+5VDC

I Turn off temperature keeping function

J Adjust and set temperature upper and lower

limits

K Adjust and set temperature upper and lower

limits

L Check SSR, fuse, terminal, circuit,

heater band, etc.

M Check or replace thermocouple

N Exchange thermocouple wire + , -

connection

Loading...

Loading...