Injection Molding Machine Chapter 5

V3.0

5-8

2.2

Warning contents and maintenance message indicated

M:Manual operation S:Semi-auto operation A:Auto operation

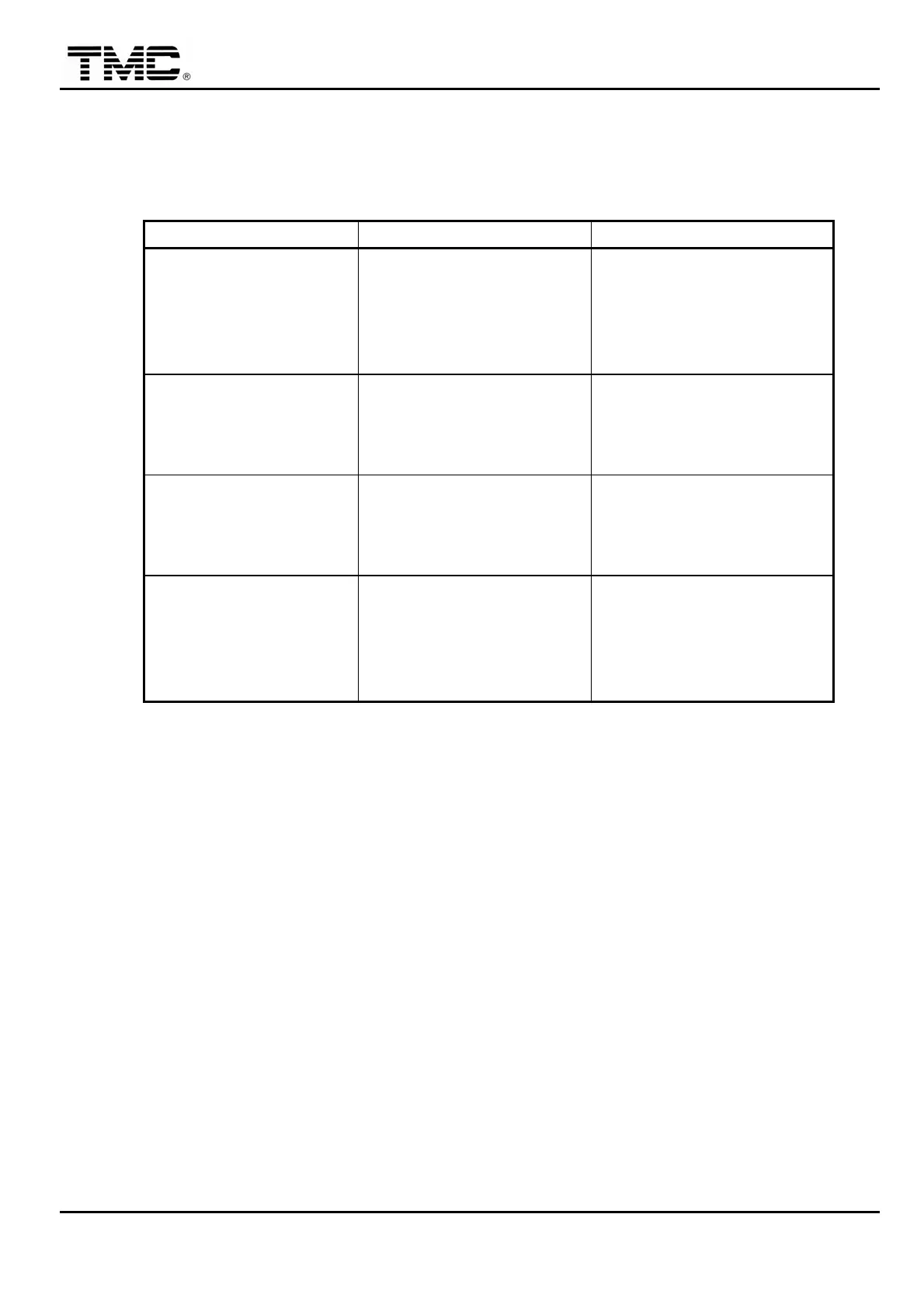

Alarm Massage Cause of Alarm Reset of Alarm

01. Mold protection

Please check mold

and mold protection

time

S/A:T/C 324 mold clam

protection time over

1. Open safety gate

2. Adjust T/C 324 set value

3. Adjust mold clamp low

pressure to high pressure

position set value

02. Lubrication oil

shortage

Please check lub. oil

& input no. 213 ,214

1. M/S/A: I/O 213 ON,

IO214 OFF

2. T/C 361- I/O 214 OFF

when lubrication over

1. Open safety gate

2. Check lubrication oil level

3. Check lubrication piping

and pressure switch

04. Cycle time over

Please check full

cycle status

S/A: T/C 321 exceeded 1. Open safety gate

2. Adjust T/C 321set value

3. Check actual operation

status of machine

05. Injection time over

Please check

injection settings

S/A: T/C 385-injection

monitor time over

1. Open safety gate

2. Adjust T/C 384 set value or

P/V TRANS. POINT

3. Check mold and nozzle for

blockage

Loading...

Loading...