Injection Molding Machine Chapter 5

V3.0

5-15

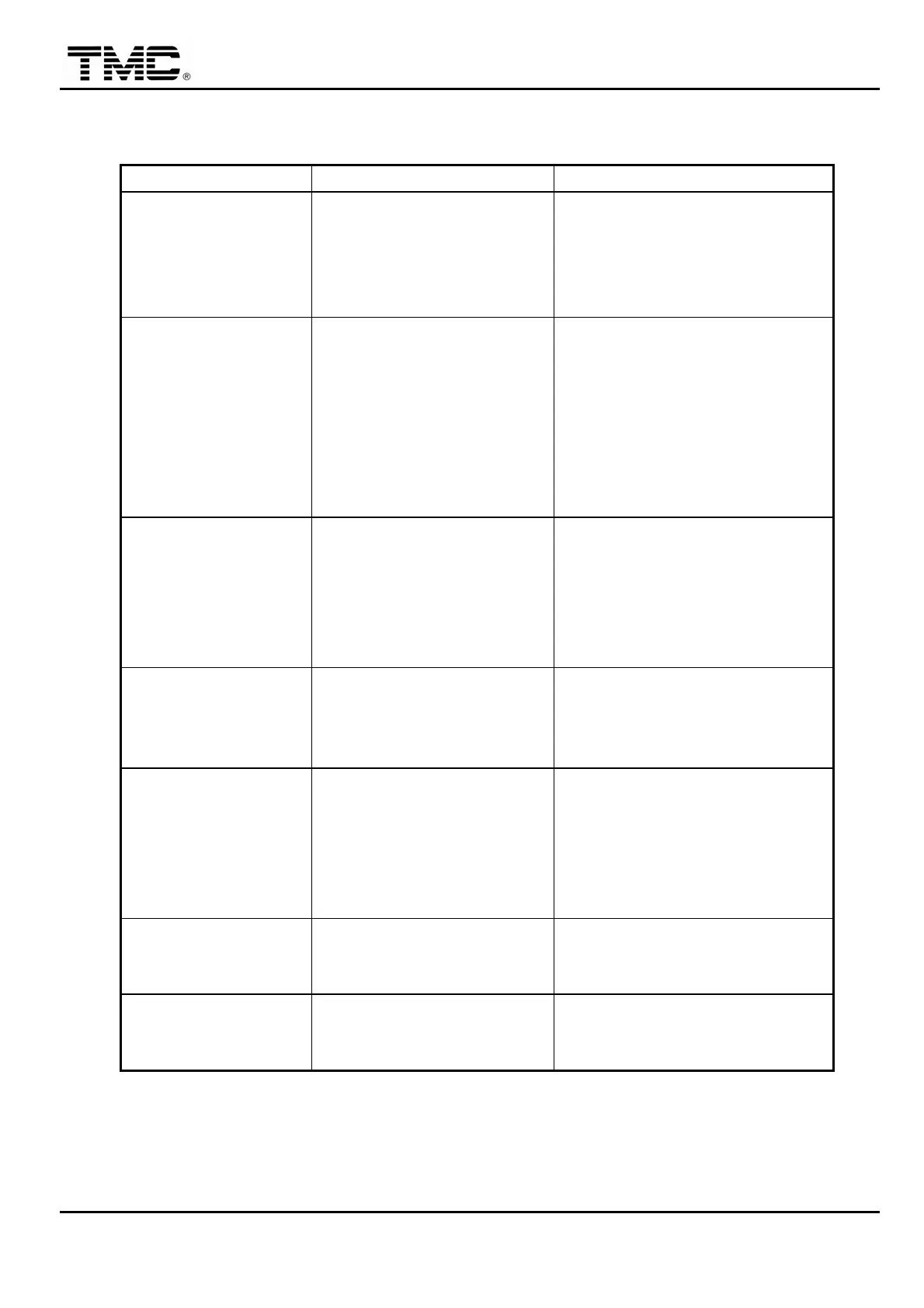

3. Hydraulic part

Symptom Possible causes Solution

3.1 Pump noisy A Sucking side air leakage

B Coupling damaged

C Motor damaged

D Pump damaged

A Check O ring or packing on

filter suction line

B Check rubber gasket of coupling

C Check motor

D Check pump

3.2 No system pressure A PV board damaged or

improper adjustment

B PV fuse burnt out or no

power

C Loose wiring of proportion

valve

D Proportion valve

seizure/damage

A Adjust PV board or replace

B Check or replace fuse (2A),

Replace transformer PT2

C Check proportion valve

connecting wire

D Clean/replace proportion valve

3.3 Pressure unstable

A Air is in proportion valve

B Suction pipe air leakage

C Oil viscosity too low or too

high

D Oil contaminated

/deteriorated

A Expel air in proportion valve

B Check according to 3.1 above

C adjust oil temperature(20-50℃)

D change hydraulic oil

3.4 Vibration during

operation

A Air in system line

B lubrication not enough

C Hyd. cylinder damaged

A Expel air in cylinder or system

line

B more lubrication

C. Check hydraulic cylinder

3.5 Machine

inoperative

A Pressure insufficient

B Flow insufficient

C Directional valve no signal

D Directional valve seized

E Hyd. cylinder leakage

F Back pressure too high

A Increase pressure

B Increase flow

C Check signal wire & terminal

D Clean direction valve

E Replace piston oil seal

F Decrease back pressure

3.6 Hydraulic system

oil leakage

A Oil pipeline connector

loosened

B Hyd. hose aged

A Tighten the bolt or nut

B Replace hydraulic hose

3.7 Cylinder leakage A Bolt loosened

B Cylinder oil seal

damaged/aged

A Tighten nuts

B Replace cylinder oil seal

Loading...

Loading...