Injection Molding Machine Chapter 7

7-2

V3.0

CAUTION

Center height of nozzle has been adjusted upon factory delivery, unless injection

base deflection is confirmed,it is better not to make any adjustment arbitrarily.

Machine Model 60E 90E 120E 150E 200E 250E 350E

Locating ring

φ100×φ150×15 depth φ150×φ200×15 depth

Machine Model 500E 750E 1000E

Locating ring

φ150×φ250×15 depth φ200×φ300×15 depth

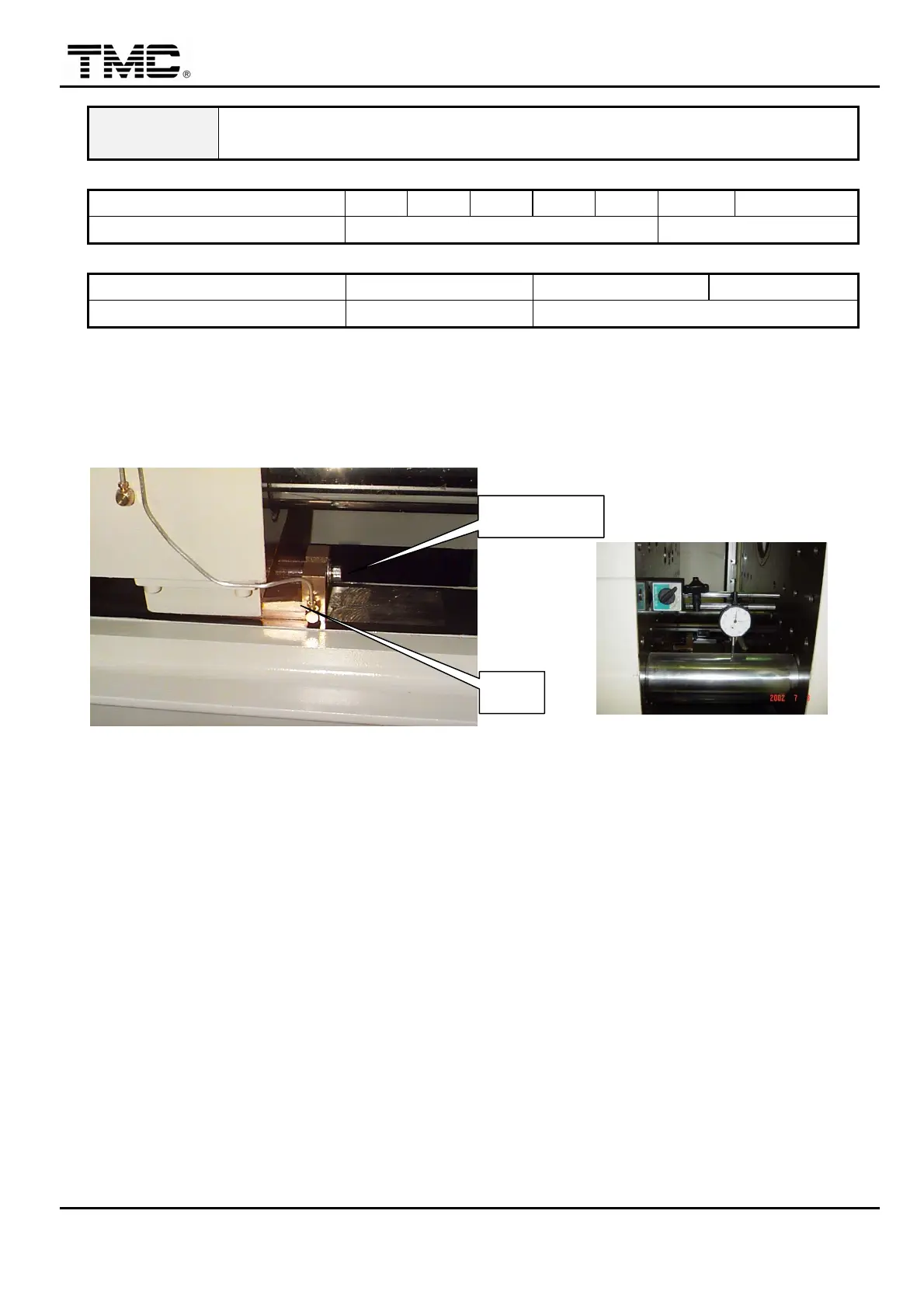

1.2 Adjustment of moving platen shoes

The purpose of this adjustment is to make the four tie bar holes,fixed platen and moving platen to be

on the same central line. Adjustment procedures are as follows:

A) Confirm that no mold is set between platens.

B) Loosen the nut that secures 1251,pull the shoe out.

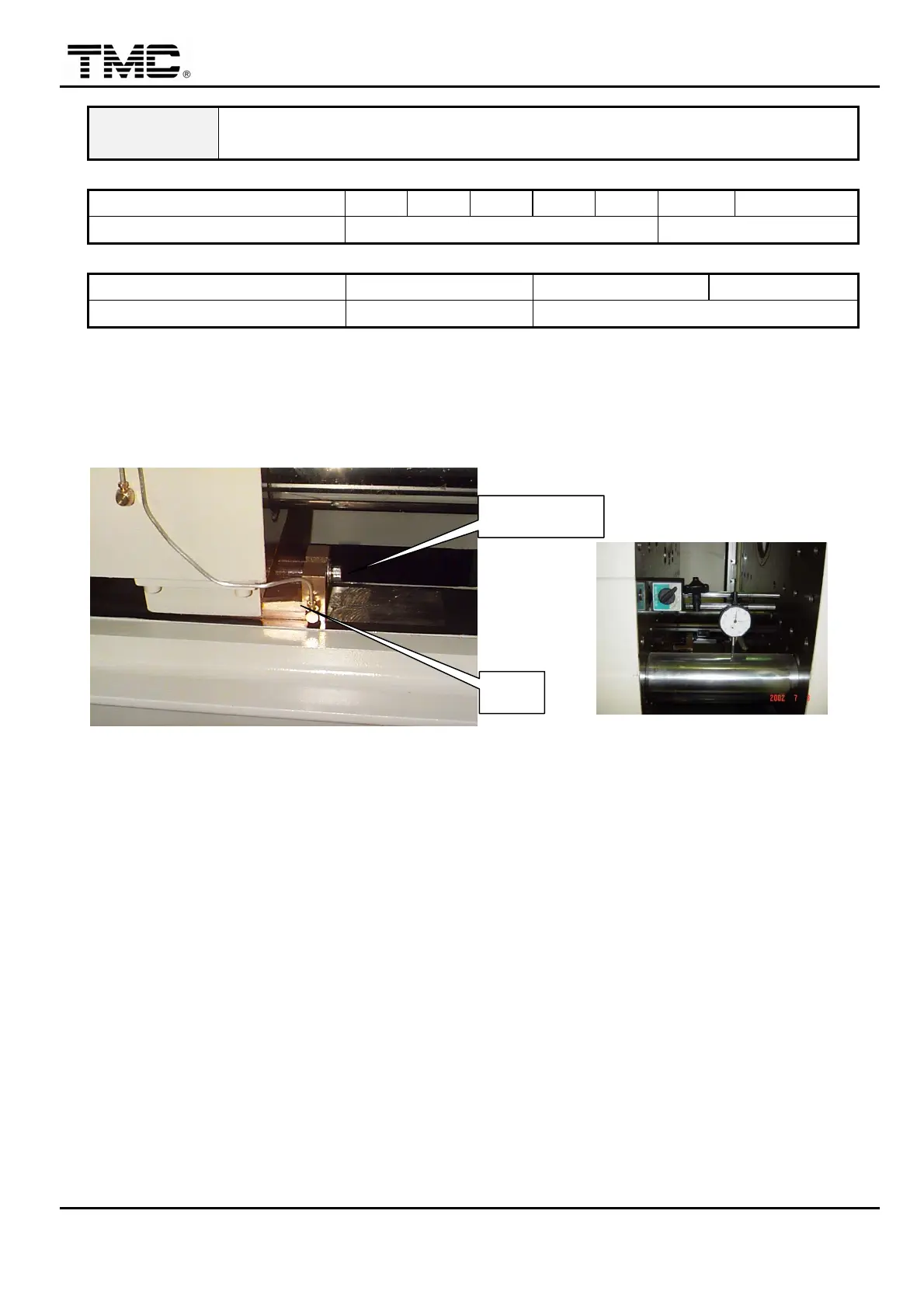

C) Mount a dial gauge on moving platen, measure the vertical displacement of tie bar.

D) Pushes the shoe into mating slant slot by hand.

E) Tighten up adjusting bolt and nut until dial gauge reads 0.02 more.

F) Apply sufficient grease.

G) Perform clamp open/close with maximum stroke for several times to confirm that height has been

properly adjusted.

Shoe

Fixing bolt

Loading...

Loading...