Injection Molding Machine Chapter 4

V3.0

4-9

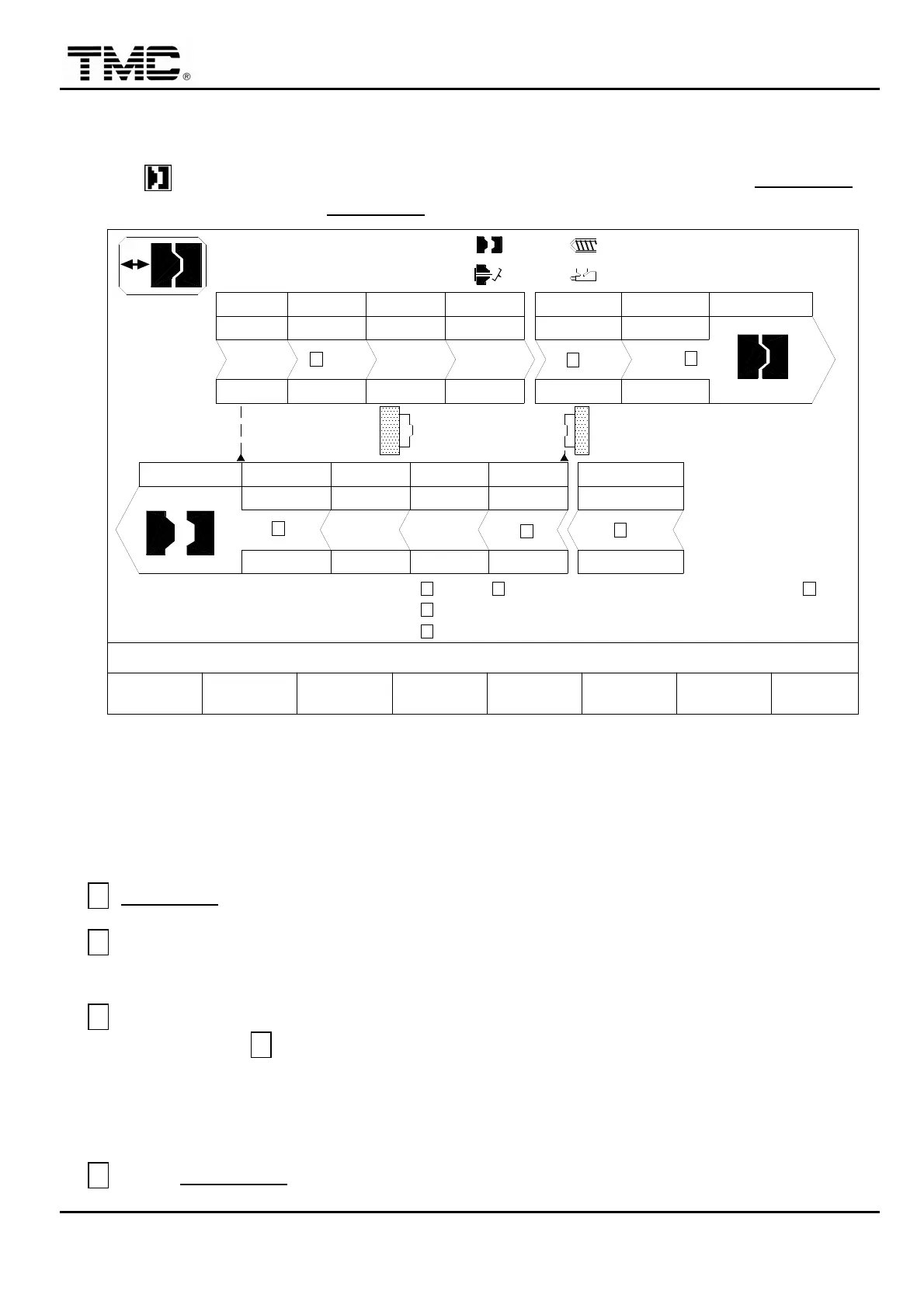

2.3

Clamp open/close setting

Press hot key or use directional key in the main menu to move the cursor to CLAMPING

and press ENTER to display CLAMPING screen.

V %

PT mm

P Bar

DECOMPRESS

LOW P/V LOCK CLOSE END

PT mm

P Bar

V %

V1: 0/ 0 0/ 0V2:

0/ 0P1: 0/ 0 P2:100.0mm

100.0mm

210.0mm

0.5mm

M:

03D05M07Y

10h25m10s

20°C3W

MOLD PROTECTION T.

CLOSE MONITOR T.

OPEN MONITOR T.

< 1.0> 0.0

< 5.0> 0.0

< 5.0> 0.0

< 1.0> 0.0

< 20.0> 0.0

ROBOT SIGNAL PT. / T.

CYCLE T.

INTERVAL T.

14020

220 40.0

1020

0

50.0

10 100

5.0

100

10

PARAMETER

CLAMP

F2F1 F3 F4 F5 F6 F7 F8

MOLD ADJ. LOG SUPPORT TENANCEMENU

01

I/O

<220.0/ 5.0> OFF

OPEN END

120.0

50

90

4'S3'S2'S1'S

180.0

50

4'S3'S2'S1'S

100

100

50

CHANGE MOLD EXTERN MAIN-

A

B

C

D

E

F

G

H

I

KJ

ACTION STATUS

Screen 4-6

V %

:

Speed setting in percentage

,

0%~100%.

PT mm

:

Position setting

,

uses the

※

on the panel to input decimal point.

P bar

:

Pressure setting.

A

OPEN END

:

Clamp open end position.

B

If the contact force of male and female mold halves is too strong

,

increase switching

position set value of rapid to low speed for earlier speed slow down.

C

Setting of clamp close low pressure to high pressure position

:

first of all

,

set this position

to be same as

D,

do manual clamp close

,

when mold travels to the male and female

mold touch position

,

check the present value of clamp position on the upper portion of the

screen. Take this value and add 3.0~5.0 as set value in toggle model

,

for fully hydraulic

type

,

add

0.1 to be the low pressure to high pressure switching position setting.

D

Clamp CLOSE END position

:

Toggle type is set at 5.0

:

Fully hydraulic type is set at 0.0

,

Loading...

Loading...