Injection Molding Machine Chapter 4

V3.0

4-11

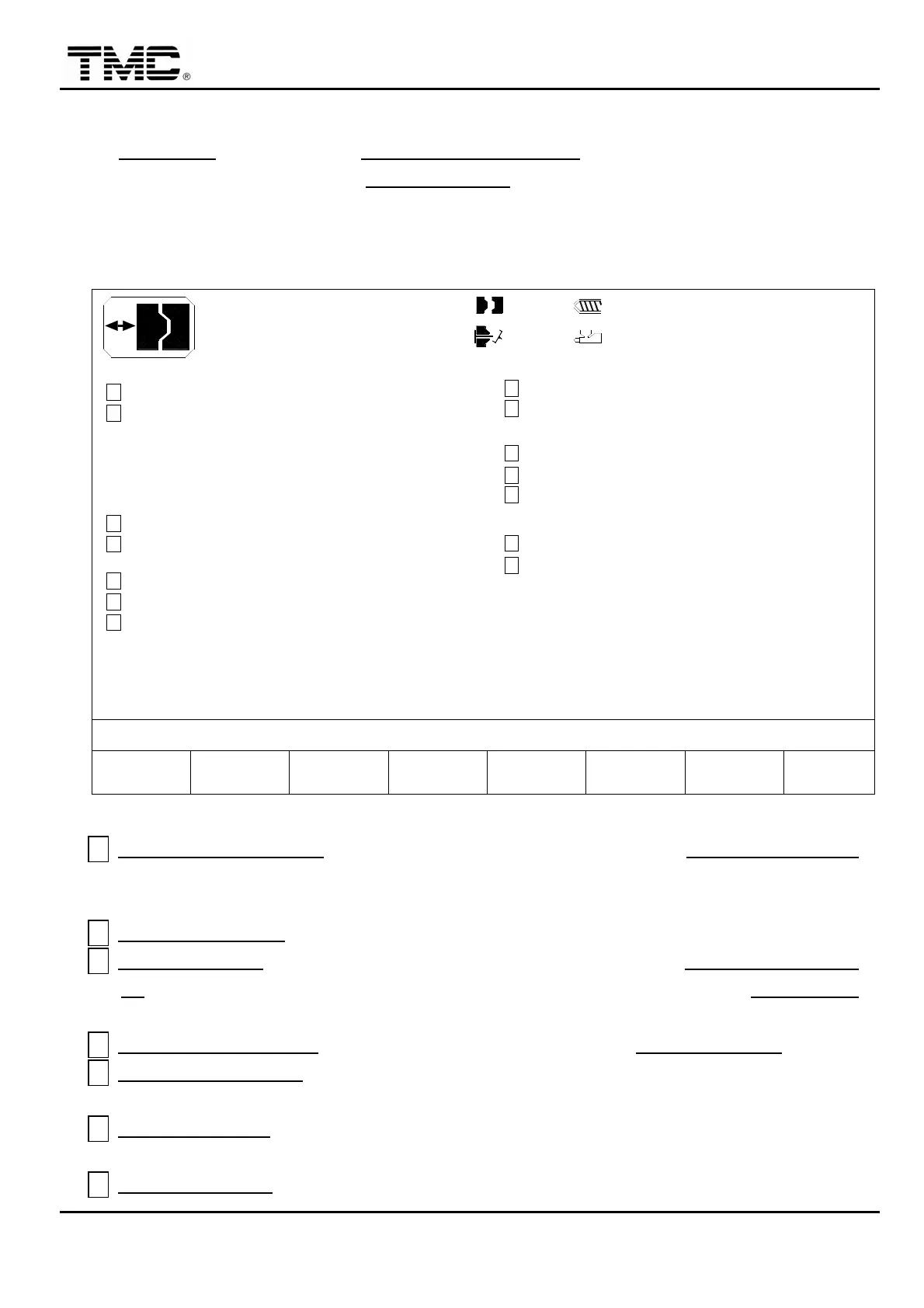

2.4 Clamping parameters

On CLAMPING screen press F2 CLAMPING PARAMETER

,

or use the directional key in the

main menu to move the cursor to CLAMPING REF.

,

press ENTER if the massage area show

[Lock mode key in password…02]

,

after the correct password is input

,

press ENTER twice to

access to this screen. (Press ENTER the first time is to confirm the password while press

ENTER the second time is to display the screen.)

V1: 0/ 0 0/ 0V2:

0/ 0P1: 0/ 0 P2:100.0mm

100.0mm210.0mm

0.5mm

ACTION STATUS

M:

03D05M07Y

10h25m10s

20°C3W

CLAMP DECOMPRESS

RE-CLOSE COUNT

OFF

< 0 > 0

F2F1 F3 F4 F5 F6 F7 F8

MOLD ADJ. LOG SUPPORT TENANCEMENU

20

I/O

EJECT ON FLY PT.

< 20.0> 0.0

LUBRICATION T.

< 100 > 10

LUB. COUNT

<200.0>

CLAMP PRESS SLOPE

OFF

OFF

CLAMP SPEED SLOPE

INJ. COMPRESS

OFF

< 45.0>

MOLD COMPRESS PT.

OFF

INTERVAL T. COUNT

OFF

CHARGE ON FLY

CLOSE RELEASE

OFF

OPEN

CLOSE

< 2 >

< 2 >

SECTION

SECTION

RAMP

DECOMPRESS PT.

< 50.0>

< 300 > 0

HR

mm

mm

P/V CHANGE MOLD EXTERN MAIN-

E

H

G

B

A

D

C

F

I

J

K

M

L

N

GREASE LUB. T. *1hr

Screen 4-7

A CLAMP DECOMPRESS:After screw charge,the mold open to DECOMPRESS PT.

position and stop waiting for the completion of cooling,then open again to open end

position.

B DECOMPRESS PT.

:Clamp pre opening position for clamp decompression function.

C INJ. COMPRESS:When this function is on,mold close will stop at MOLD COMPRESS

PT.,then injection starts,after injection process is finished,mold close to CLOSE END

position. This can achieve single stage injection compression.

D MOLD COMPRESS PT.:Mold close midway stop position for INJ. COMPRESS function.

E INTERVAL T. COUNT:Disable interval timer when set on,usually used in mold setup

mode.

F CHARGE ON FLY:Option feature. When set on,mold can be opened while charge is still

in progress.

G CLOSE RELEASE

:When set on,performing sensitive mold protection function by

Loading...

Loading...