Injection Molding Machine Chapter 4

V3.0

4-20

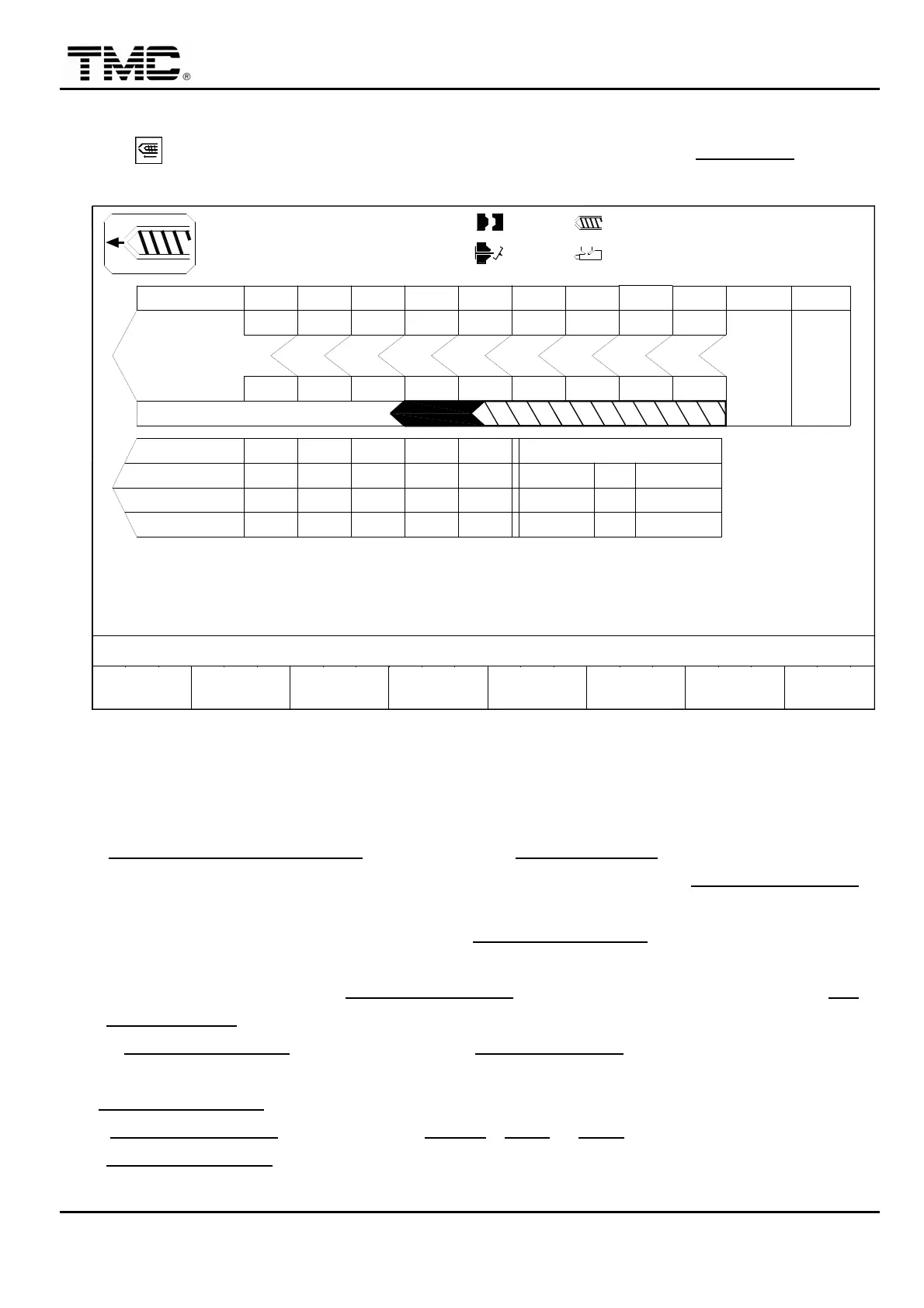

2.9 Injection setting

Press hot key or use the direction key to move the cursor to the INJECTION

,

press

ENTER to display this screen.

10h25m10s

20°C

CUSHION MONITOR:LOW

30

40

PARAMETER

INJ. MONITOR T.

0.50

03D05M07Y

INJ.

F2F1

MENU

04

INJ. DELAY T.

COOLING T.

5

HOLD P.

V %

TIMEsec

P bar

40

10

PT mm

P bar

10.0

INJ.V

V %

9

3W

< 8.0>

INJ. PRESS ACTUAL

000

,HIGH

< 9.0>

INJ. SPEED ACTUAL

INJ. START PT.

INJ. END PT

MOLD

SUPPORT

F3 F4

AUTO INJ.

PURGE PROFILE

< 0.0> 000.0

< 4.0> 000.0

F5 F6

CHANGE

LOG

PROD.

MANAG.

F7 F8

FUNCTION

000.0

000

000.0

100.0mm

100.0mm

10

P/V TRANS. POINT

< 10.0>

<1.0>

< 000>

140

50.0

432

10

60

0.50

50

0.50

10

70

0.50

10

100.0sec

140

20.0 30.0

40.0

140 140

1

PT mm

TIME

P bar

140

10

0.50

OFF

OFF

ON

70.0

140

60.0

140

140

80.0

78

50 60 70

6

1.0mm

9080

54

100

32

110.0mm

9.9

0.6

000

105.0

100.0

140

+10.0

0/ 0

0/ 0

SUCK.B

0/ 0

CH.END

1

15

P1: P2:

0/ 0V1: V2:

ACTION STATUS

M.:

Screen 4-12

2.9.1 Three major stage of injection V / P

V Injection speed control

1. INJ. SPEED < > SECTION

can be set on the INJECTION PAR. screen.

2. It is recommended to set low speed to 10~20%. 3.0~10.0 mm before P/V TRANS. POINT

position.

3. It is recommended that the pressure before P/V TRANS. POINT should be the reading of

actual maximum injection pressure plus 10 bars.

4. All pumps are active before P/V TRANS. POINT while only small pump is active after P/V

TRANS. POINT thus reduces energy consumption.

5. If P/V TRANS. POINT is not reached before INJ. MONITOR T. times up

,

alarm is fired.

/ P/V TRANS. POINT

1. P/V TRANS. POINT

: One or more of PT mm

,

TIME

or P bar must be selected to control

P/V TRANS. POINT

,

any one condition is made

,

injection filling process will be switched to

holding process.

Loading...

Loading...