Injection Molding Machine Chapter 4

V3.0

4-30

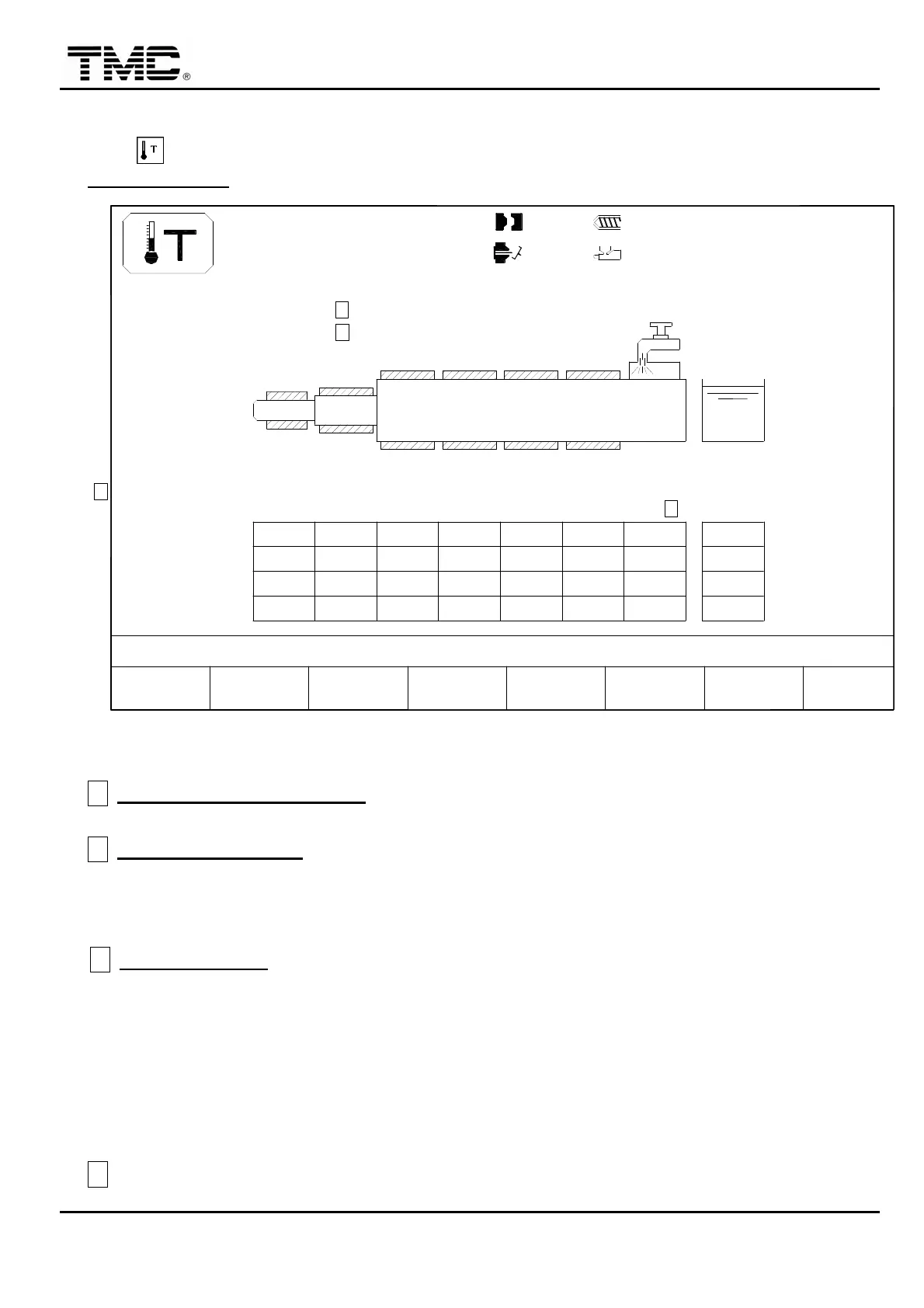

2.14 Temperature setting

Press hot key or use the direction key on the main screen to move the cursor to

TEMPERATURE

,

press ENTER to display this screen.

10h25m10s

20°C

PARAMETER

<80>

READY

03D05M07Y

POWER SWITCH

ON

F2F1 TEMP

MENU

01

HIGH ALARM

LOW ALARM

20

10

C

PRESET TEMP

ACTUAL TEMP

ALARM STATUS

ZONE NUMBER

210

210

OK

H1

ON

TEMP CONDITION

TEMP KEEPING %

3W

ON ON ON ON ON ON OFF

ALARMF3 F4 INJ.

PROFILE

20

10

20

10

20

10

F5 F6CHANGE

LOG LOG

20

10

20

10

20

10

TEMP

KEEP

F7 F8DIAGNO

-STIC

20

10

100.0mm

50.0mm

D

210

210

H2

OK

210 210

210 210

OK

H3

OK

H4

ON ON ON

210

210

H5

OK

210 42

210 45

OK

H6

OK

H7

ON OFF

DANGER/HEATER CUT OFF

COLD START T.min.

A

B

1.0mm

<10.0>

<400>

10.0

110.0mm

HYD.OIL

45

45

OK

OFF

0/ 0

0/ 0 0/ 0P1: P2:

0/ 0V1: V2:

ACTION STATUS

M:

Screen 4-17

A

DANGER HEATER CUT OFF

:

Usually set to maximum temperature +50

℃

.

B

COLD START T. min.

:

Each time the heater is on

,

after read temperature in every zones

reaches to the set temperature within 5

℃,

cold start protection timer starts counting

,

screw is only allowed for operation after completion of the timer.

C

ALARM STATUS

:

O.K.

Actual temperature is in the range of set temperature

+

(high

limit)

,-

(lower limit)

HI

Actual temperature exceeds set temperature

+

high limit

LO

Actual temperature is below set temperature

-

low limit

ABN

heating circuit disconnected

,

please check SSR

,

FUSE and

heater band

INV Thermocouple wire is connected inversely

DIS Thermocouple wire is disconnected

D

H7 is the temperature of water collar.

Loading...

Loading...