space (1mm), then the working space should be adjusted over again, and if

abrasion of friction disc near to the aluminum core, the brake disc should be

replace in time, otherwise, the brake device can be damaged.

c) Gearing: cleaned and grease lubricated (i.e.no.1) every year.

d) Bearing: cleaned and grease lubricated (i.e.no.1) every year.

e) Hooks: to be checked periodically for the deformation and abrasion measurement,

if t

he wear or deformation measures up 10% of the standard sizes (ref to illustrated

figure), please change the hooks.

f) Hooks: to be checked periodically for the deformation and abrasion measurement,

if t

he wear or deformation measures up 10% of the standard sizes (ref to illustrated

figure), please change the hooks

3) Repairing warning

Once the hoist damaged or can not be operated normally, shall consult with local supplier

or

the designated maintenance, users are not allowed to open or repair the hoist by

themselves.

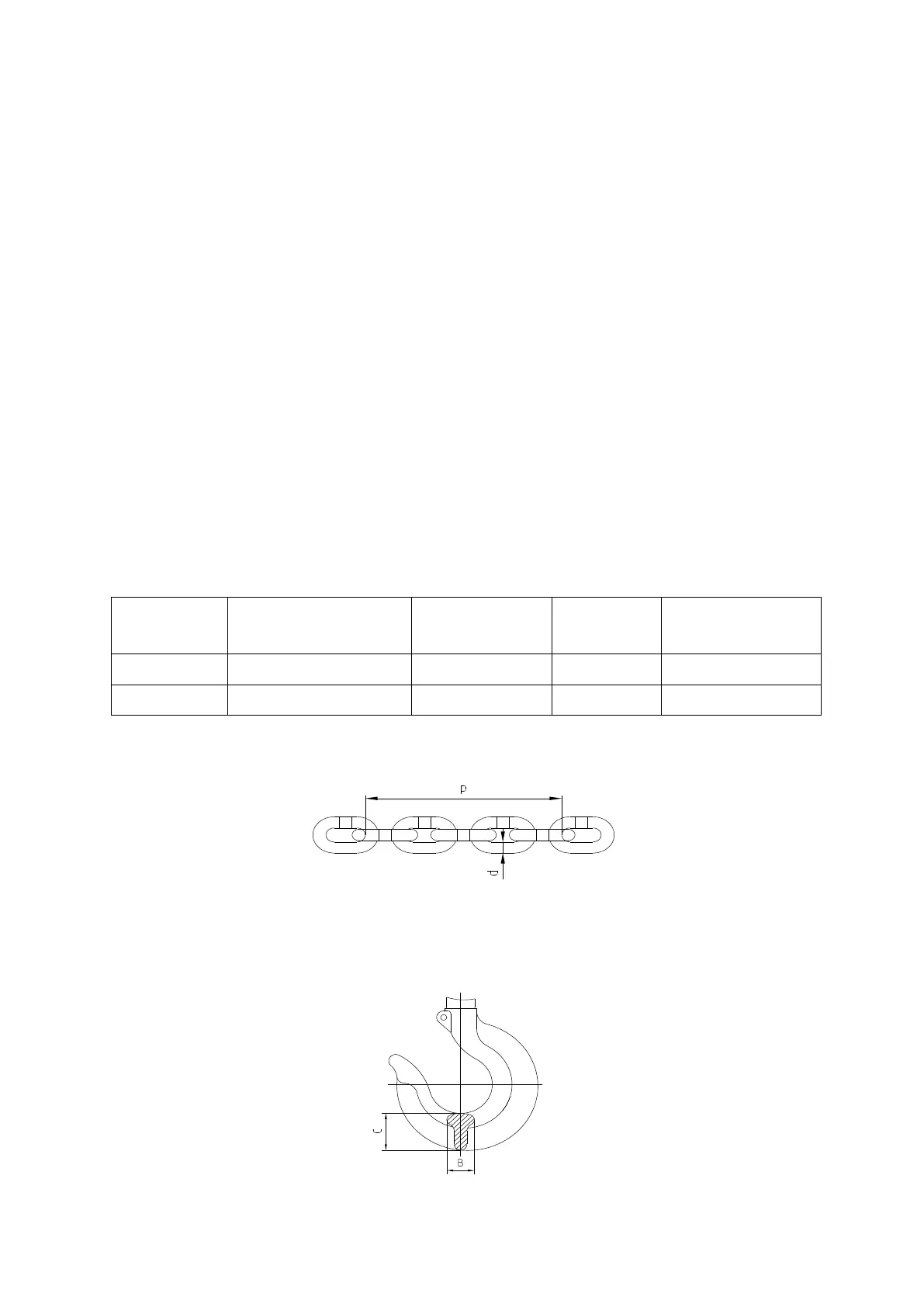

4) Illustration figure for chain inspection

If chain is abraded over the limit value, which must be replaced with a new one.

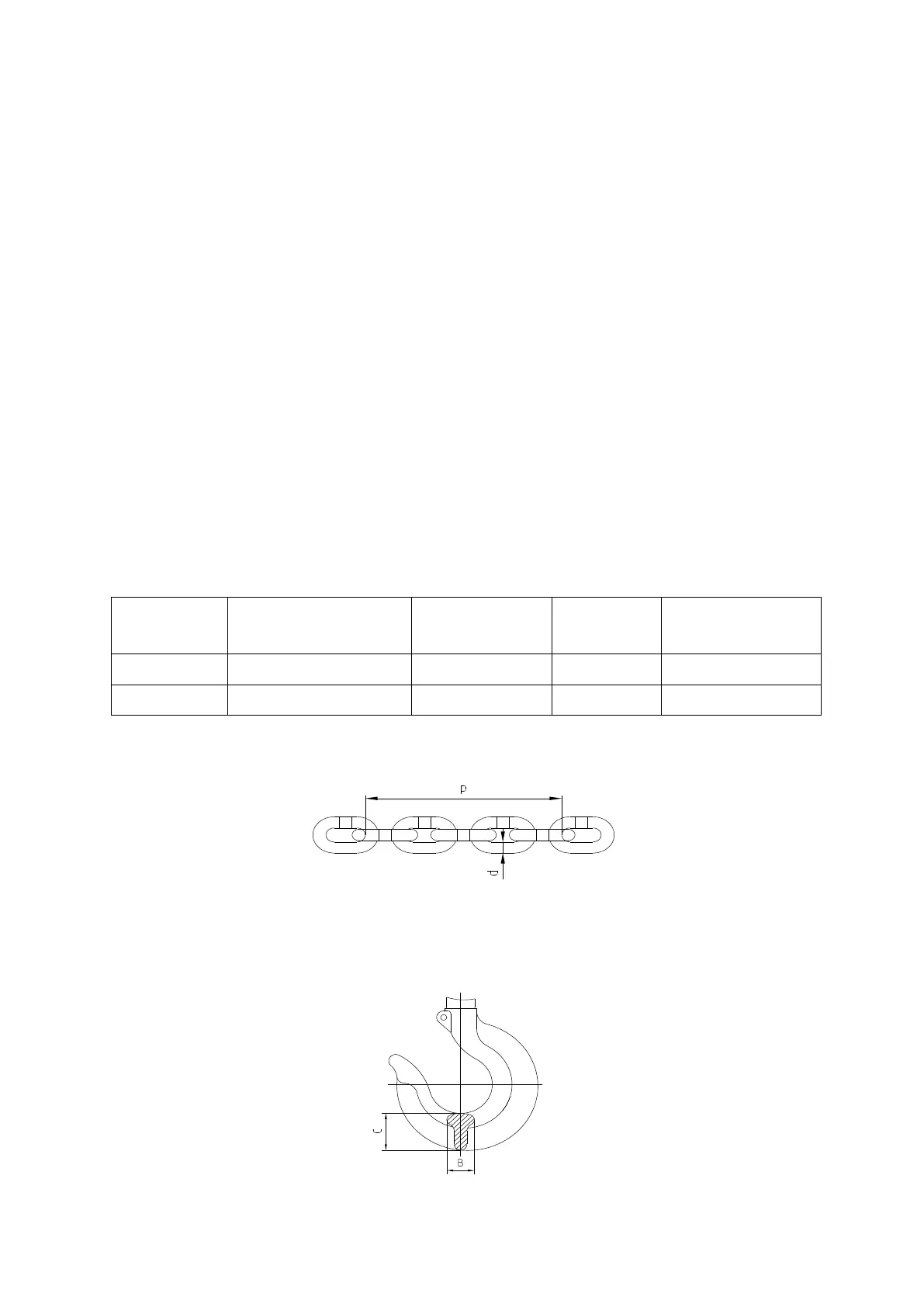

5) Illustration figure for hook inspection

If the size

o

ne.

“b” and “c” is smaller than the 90% of the standard size, please replace with new

Dia. of chain

(d)

Wearing Limit value

(d)

Measure links

standard

value

(p)

Wearing Limit

value (p)

5mm

4.5mm

5

75.5mm

77.8mm

7.1mm

6.4mm

5

106mm

109.2mm

4

B (mm) C (mm)

capacity (t)

Normal Size Abnormal Size Normal Size Abnormal Size

0.5 19 17 26 23.4

1 19.5 17.5 27 24.3

2 22 19.8 32 28.8

3 24 21.6 35 31.5

8 Malfunctions and settlement

NO. Malfunctions Causes Settlements

Wires unconnected or

loose result power off

Check and fasten all the

wire connection points.

1

The hoist refuse to

operate under switch on

Electrical parts damaged Replace the damaged part

2

Hoist refuse to

operate, and the

braking parts has

wuwu bee noise.

Voltage is too low.

Operate under rated

vol

tage.

Dust or oil on brake disc Clean the disc

3

After switch off, the

load

drop while

braked

Severe abrasion of disc Replace the disc

4

Hoist still operate

while t

he control

button released

The conductor damaged Replace conductor

The chain no lubricated

properly

Lubricate chain by oil or

grease

5

Chain run with

str

ange noise

The chain or sprocket

whe

el worn

Change with new ones.

The earth connection is

not ok

Ensure good earth

connection

High humidity in the air Improve the environment

6

Leakage of

elec

tricity

Dust on the electrical

parts

Keep the parts clear to dust

5

.

Loading...

Loading...