RIGHT HAND MITERING

FIGURE

30

FIGURE

29

FIGURE

31

CROSSCUTIING

RIPPING

7

0.

It

is

important that the bearings be

in

line from front to back on

the track ·arm.

To

check this, apply some light grease to the tracks

of

the rotating arm. Wipe the grease down to a thin film. Then pull

the carriage to the front stop

of

the track and push it back to observe

the tracks left

in

the grease. There should be only one mark, the

width

of

the bearing face. If the bearings are

not

moving in the

same line, you must make further adjustments. If the front bearings

are higher than the rear, tighten the rear hex screw. If the front

bearing

is

lower, you' must tighten the front hex bolt. This adjust-

ment

is

important

in

keeping your saw

SQuare

for ripping operations.

The

felt

track wipers on each side

of

the right

and

left hand dust

covers

will

wear and should be adjusted occasionally so

that

sawdust

won't pile up on the track

and

cause a bind

in

the crosscut travel.

I.

Loosen the screws

in

the metal backing plates.

2.

Slide each felt wiper down until it fits snugly against the track

and

tighten the screws.

TO

ADJUST

FELT

TRACK

WIPERS:

OPERATIONS

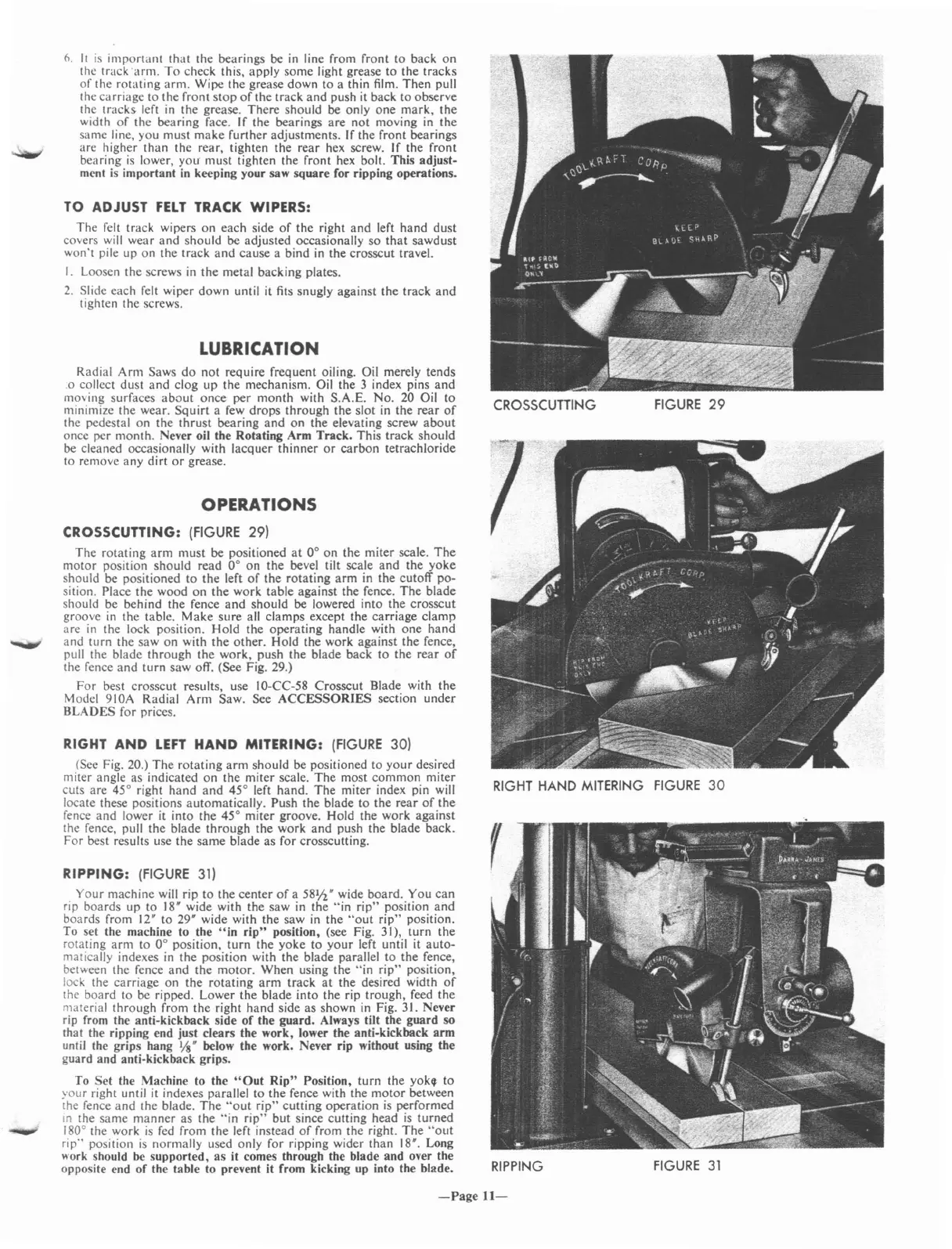

CROSSCUTTING:

(FIGURE

29)

The rotating

arm

must be positioned

at

0° on the miter scale.

The

motor position should read 0° on the bevel tilt scale and the yoke

should be positioned to the left

of

the rotating arm

in

the cutoff po-

sition. Place the wood on the work table against the fence.

The

blade

should be behind the fence and should be lowered into the crosscut

groove

in

the table. Make sure all clamps except the carriage clamp

are

in

the lock position. Hold the operating handle with one hand

and turn the saw on with the other. Hold the work against the fence,

pull the blade through the work, push the blade back to the rear

of

the fence and turn saw off. (See Fig. 29.)

For

best crosscut results, use IO-CC-58 Crosscut Blade with the

Model 910A Radial

Arm

Saw. See

ACCESSORIES

section under

BLADES for prices.

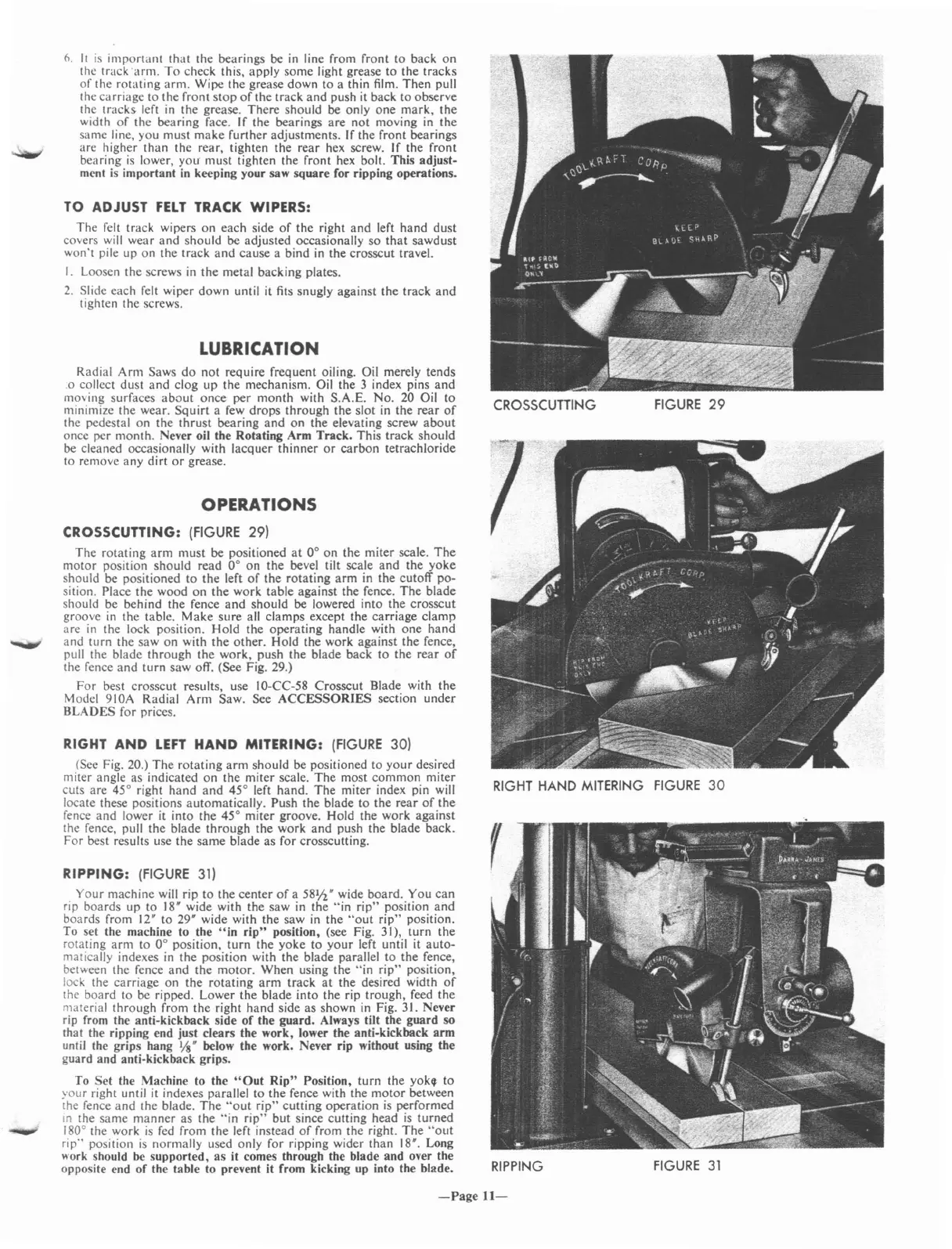

RIGHT

AND

LEFT

HAND

MITERING:

(FIGURE

30)

(See Fig. 20.)

The

rotating

arm

should be positioned to

your

desired

miter angle as indicated on the miter scale.

The

most common miter

cuts are 45° right hand

and

45° left hand.

The

miter index pin will

locate these positions automatically. Push the blade to the rear

of

the

fence and lower it into the 45° miter groove. Hold the work against

the fence, pull the blade through the work and push the blade back.

For best results use the same blade as for crosscutting.

Radial Arm Saws

do

not

require frequent oiling. Oil merely tends

.0

collect dust and clog up the mechanism. Oil the 3 index pins

and

moving surfaces

about

once per month with S.A.E. No. 20 Oil to

minimize the wear. Squirt a

few

drops through the slot

in

the rear

of

the pedestal on the thrust bearing

and

on the elevating screw

about

once per month. Never oil the Rotating Arm Track. This track should

be cleaned occasionally with lacquer thinner

or

carbon

tetrachloride

to remove any dirt

or

grease.

LUBRICATION

RIPPING:

(FIGURE

31)

Your machine

will

rip to the center

of

a 58

1

11."

wide board. You can

rip boards up to

18"

wide with the saw in the

"in

rip"

position

and

boards from

12"

to 29" wide with the saw

in

the

"out

rip"

position.

To set the machine to the

"in

rip"

position, (see Fig. 31), turn the

rotating arm to 0° position, turn the yoke to

your

left until it auto-

matically indexes

in

the position with the blade parallel to the fence,

between the fence and the motor. When using the

"in

rip"

position,

lock the carriage on the rotating

arm

track

at

the desired width

of

the board to be ripped. Lower the blade into the rip trough, feed the

material through from the right hand side as shown

in

Fig. 31. Never

rip from the anti-kickback side

of

the guard. Always tilt the guard so

that the ripping end just clears the work, lower the anti-kickback arm

until the grips hang

Ys"

below the work. Never rip without using the

guard and anti-kickback grips.

To Set the Machine to the

"Out

Rip"

Position, turn the yoklt to

your right until

it

indexes parallel to the fence with the motor between

the fence and the blade.

The

"out

rip"

cutting operation

is

performed

In

the same

manner

as the

"in

rip"

but since cutting head

is

turned

180°

the work

is

fed

from the left instead

of

from the right.

The

"out

rip"

position

is

normally used only for ripping wider than

18",

Long

work should

be

supported, as it comes through the blade and over the

opposite end

of

the table to prevent it from kicking up into the blade.

-Page

11-

Loading...

Loading...