FIGURE

41

~~mrnrnm

4040·

16

4040·17 4040·18 4040-19 4040-20

mrn~~mrn

FIGURE

.!.t,

FIGURE

43

SANDING

Arm

Saw rotates slower than a router shaper. You must compensate

for this by feeding the work

in

slower. Feed the material

by

hand to

cut

your

desired pattern.

If

you require more than a

l/S"

deep pattern,

repeat the operation as many times as necessary to reach your desired

depth. See

ACCESSORIES

section under

ROUTERS

AND DOVE-

TAIL BITS and under

ADAPTORS

for description and prices

of

necessary accessories.

DISC

SANDING

(FIGURE

44)

'Co

Mount

one

of

the Toolkraft sanding discs No. XM-834, XM-836,

or

XM-837 on the saw

arbor

to convert

your

machine to a disc sander.

See

ACCESSORIES

under

SANDING

DISCS

AND

DRUMS

for

price

and

description

of

discs. Set the rotating

arm

in

the 0° position.

Make a work

support

table

and

fasten

it

to the table top. Feed the

work into the right hand side

of

the disc as shown

in

Fig. 44.

The

guard may be left off for disc sanding work.

GRINDING:

(FIGURE

45)

To

convert

your

Radial

Arm

Saw to a grinder simply attach Tool-

kraft grinding wheel XM-1076 to the saw

arbor

shaft. See ACCES-

SORIES

under

GRINDING

WHEELS

for prices. Locate the rotating

arm

at

the 0° position

and

slide carriage

to

the reat

of

rotating arm

track. Make a tool rest as shown in Fig.

45

from any scrap lumber

approximately 4" wide

x I" thick x 6" long. Remove the fence and

insert the tool rest between the first and second table sections so that

the 0° cutoff groove

is

in the center

of

the tool rest. Raise

or

lower the

cutting head with the elevating

crank

handle until the center

of

the

wheel

is

even with the

top

of

the tool rest. Install the guard and lock

it in position to give

you

your

desired opening. Neyer grind without

the guard.

ROUTING

4040.26

4040·28

4040-29

4040-25

4040-22

4040·21

FIGURE

42

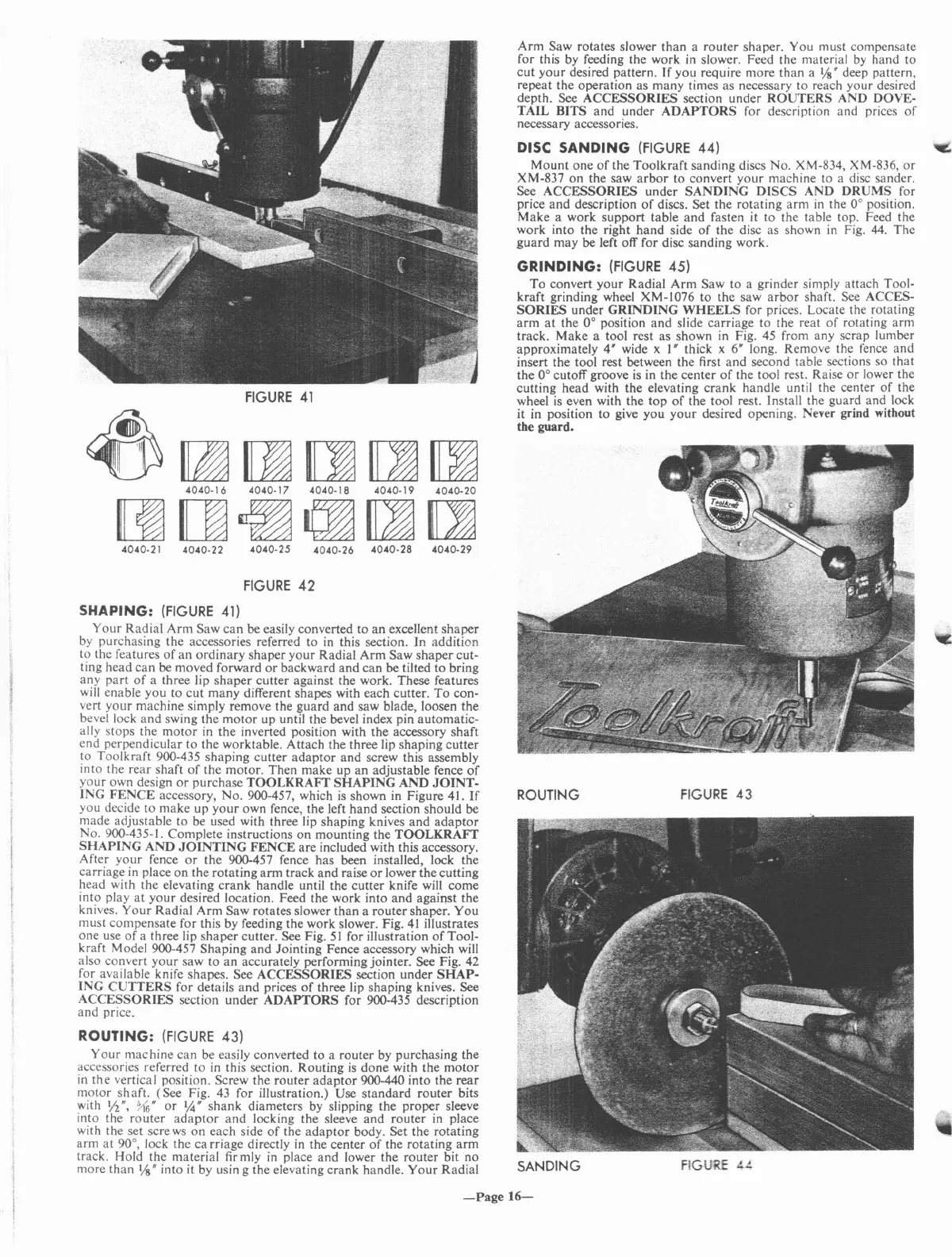

SHAPING:

(FIGURE

41)

Your

Radial

Arm

Saw

can

be easily converted to

an

excellent

shaper

by purchasing the accessories referred to in this section. In addition

to the features

of

an

ordinary

shaper

your

Radial

Arm

Saw

shaper

cut-

ting head can be moved forward

or

backward

and

can

be tilted to bring

any

part

of

a three lip

shaper

cutter against the work. These features

will enable you to cut many different shapes with each cutter.

To

con-

vert

your

machine simply remove the guard and saw blade, loosen the

bevel lock and swing the

motor

up until the bevel index pin automatic-

ally stops the

motor

in the inverted position with the accessory shaft

end perpendicular to the worktable. Attach the three lip shaping

cutter

to Toolkraft 900-435 shaping cutter

adaptor

and screw this assembly

into the rear shaft

of

the motor. Then make up an adjustable fence

of

your

own design

or

purchase

TOOLKRAFf

SHAPING

AND

JOINT-

ING

FENCE

accessory, No. 900-457, which

is

shown in Figure 41.

If

you decide to make

up

your

own fence, the left hand section should be

made adjustable to be used with three lip shaping knives and

adaptor

No. 900-435-1. Complete instructions

on

mounting the

TOOLKRAFf

SHAPING

AND

JOINTING

FENCE

are included with this accessory.

After

your

fence

or

the 900-457 fence has been installed, lock the

carriage in place on the rotating

arm

track and raise

or

lower the cutting

head with the elevating

crank

handle until the cutter knife will come

into play

at

your

desired location. Feed the work into and against the

knives.

Your

Radial

Arm

Saw rotates slower

than

a router shapero You

must compensate for this by feeding the work slower. Fig.

41

illustrates

one use

of

a three lip

shaper

cutter. See Fig.

51

for illustration

of

Tool-

kraft Model 900-457 Shaping and Jointing Fence accessory which will

also convert

your

saw to an aceurately performing jointer. See Fig. 42

for available knife shapes. See

ACCESSORIES

section under

SHAP-

ING

CUTTERS

for details

and

prices

of

three lip shaping knives. See

ACCESSORIES

section

under

ADAPTORS

for 900-435 description

and price.

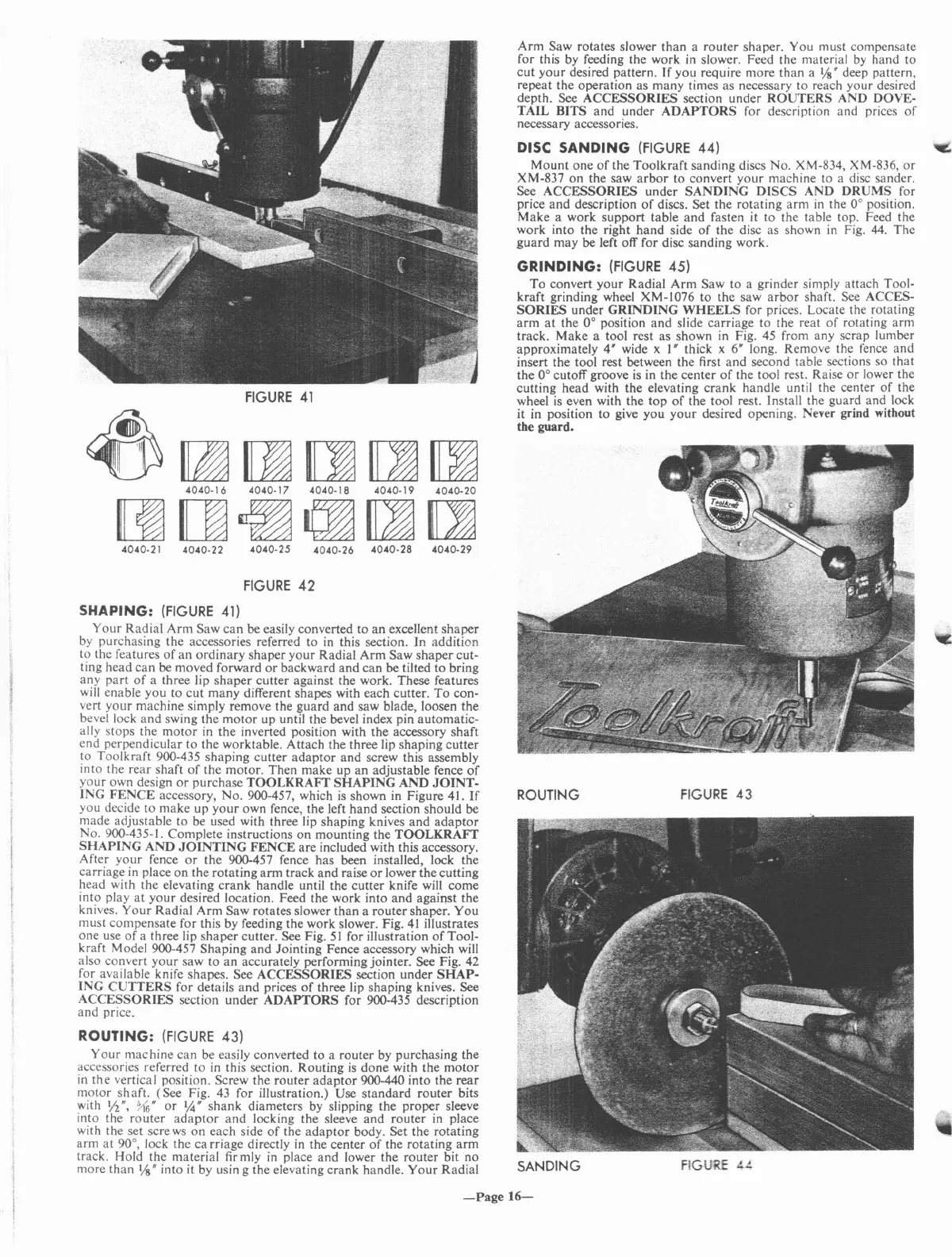

ROUTING:

(FIGURE

43)

Your

machine can be easily converted to a router by purchasing the

accessories referred to

in

this section. Routing

is

done

with the

motor

in

the

vertical position. Screw the router

adaptor

900-440 into the

rear

motor shaft. (See Fig.

43

for illustration.) Use

standard

router bits

with

1;2",

~6"

or

%"

shank

diameters by slipping the proper sleeve

into the router

adaptor

and

locking the sleeve

and

router in place

with the set sere

ws

on each side

of

the

adaptor

body. Set the rotating

arm

at

90°, lock the

ca

rriage directly

in

the center

of

the rotating

arm

track. Hold the material firmly

in

place

and

lower the router bit no

more than

Vs"

into it by usin g the elevating crank handle.

Your

Radial

-Page

16-

Loading...

Loading...