GRINDING

FIGURE

45

SURFACE

SANDING

FIGURE

46

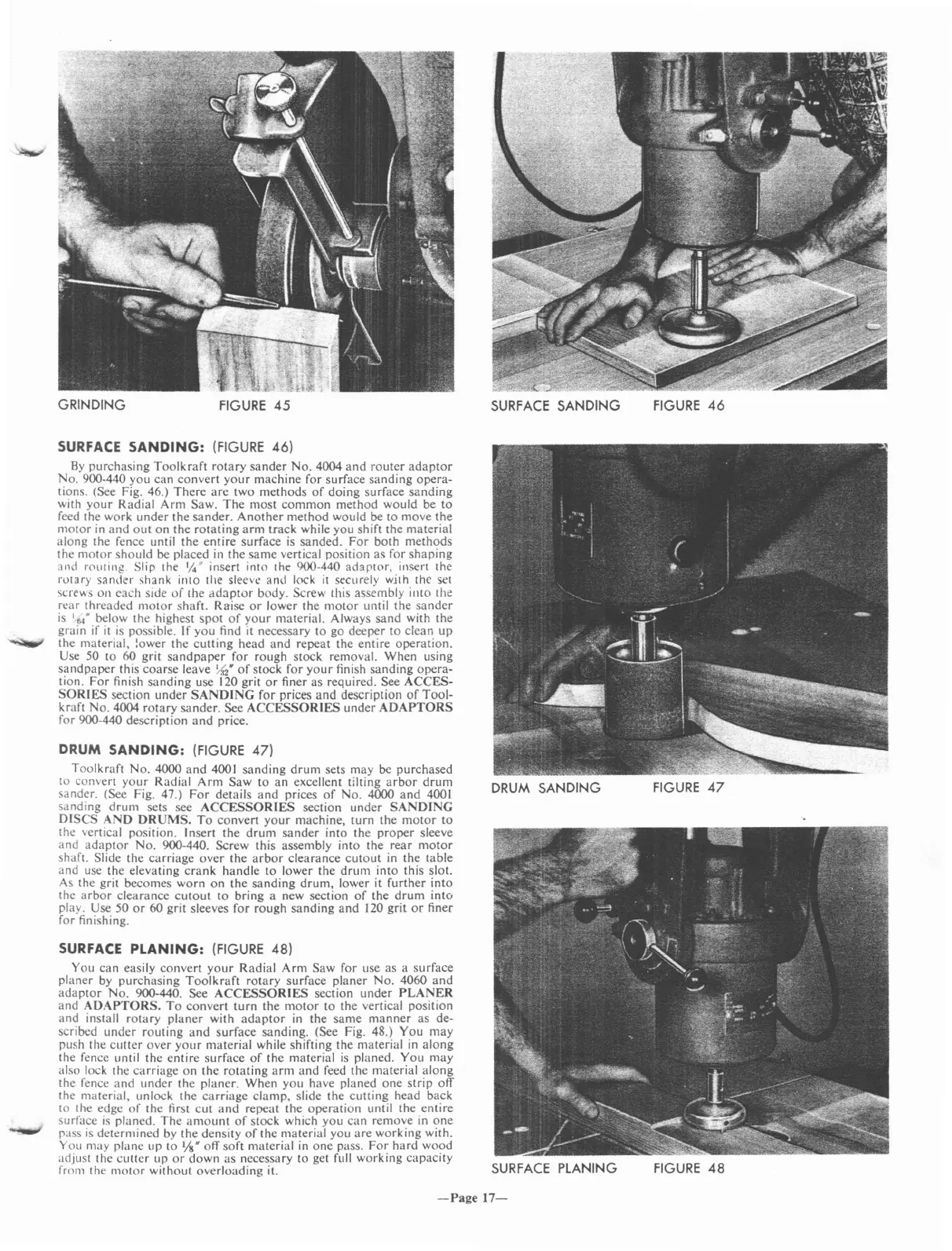

SURFACE

SANDING:

(FIGURE

46)

By

purchasing

Toolkraft

rotary

sander

No.

4004

and

router

adaptor

No. 900-440 you

can

convert

your

machine

for surface

sanding

opera-

tions. (See Fig. 46.)

There

are

two

methods

of

doing

surface

sanding

with

your

Radial

Arm

Saw.

The

most

common

method

would be

to

feed the work

under

the

sander.

Another

method

would be

to

move

the

motor

in

and

out

on

the

rotating

arm

track

while you shift the material

along

the

fence until

the

entire

surface

is

sanded.

For

both

methods

the

motor

should be placed in

the

same

vertical position as for

shaping

and rClwing. Slip the 1;''' insert into the 900-440 adaplClr. insert the

rotary

sander

shank into the sleeve

and

lock

it

securely with the set

s~rews

on

each

side

of

the

adaptor

body. Screw this assembly iuto the

rear

threaded

motor

shaft. Raise

or

lower

the

motor

until

the

sander

is

"64"

below the highest

spot

of

your

material. Always

sand

with the

grain if

it

is

possible. If

you

find it necessary to go deeper

to

clean

up

the material, :ower the

cutting

head

and

repeat the

entire

operation.

Use 50 to 60 grit

sandpaper

for rough stock removal.

When

using

sandpaper

this

coarse

leave

~2"

of

stock for

your

finish

sanding

opera-

tion.

For

finish

sanding

use 120 grit

or

finer

as

required. See

ACCES-

SORIES

section

under

SANDING

for

prices

and

description

of

Tool-

kraft

No.

4004

rotary

sander.

See

ACCESSORIES

under

ADAPTORS

for 900-440 description

and

price.

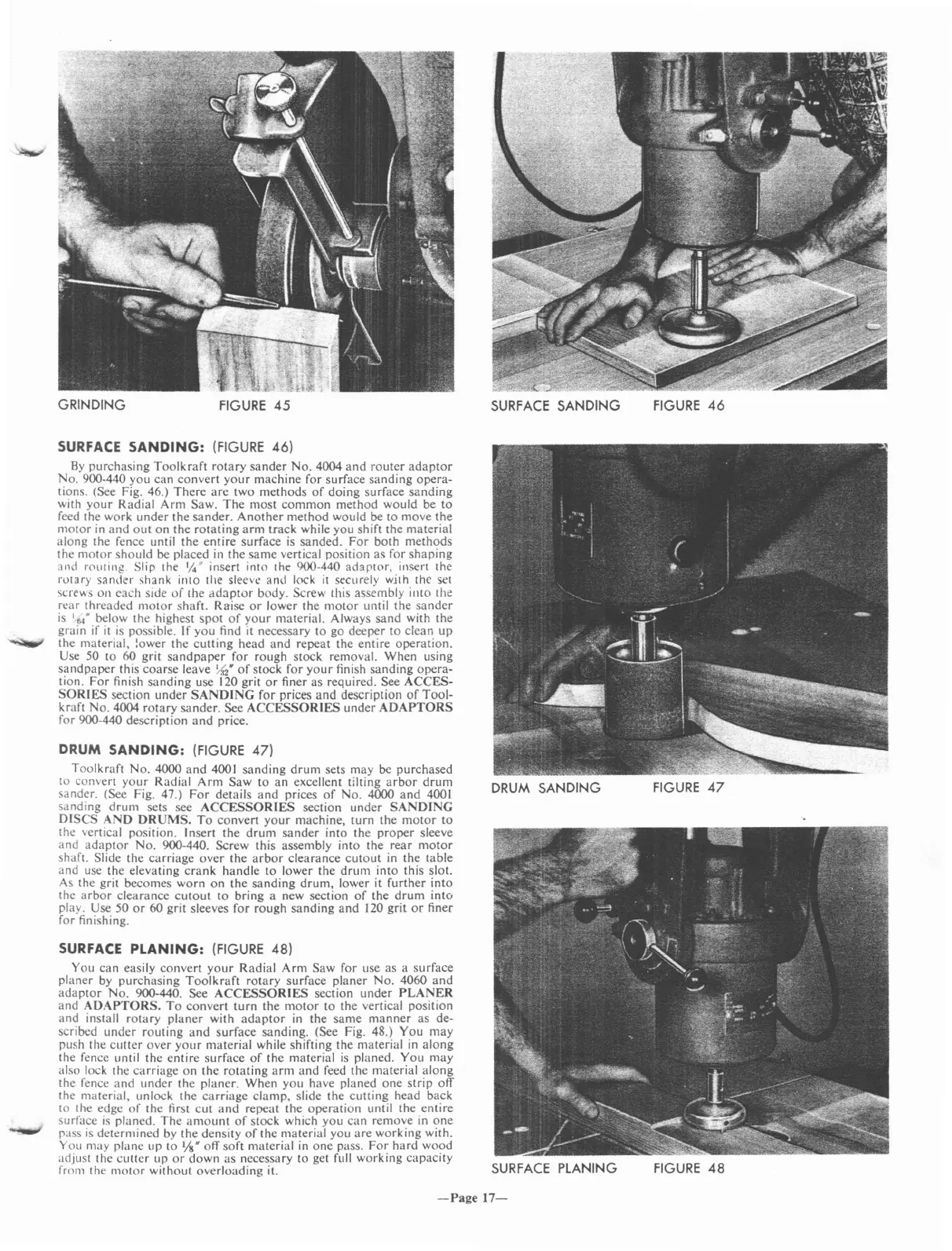

DRUM

SANDING:

(FIGURE

47)

Toolkraft

No.

4000

and

4001

sanding

drum

sets may be purchased

to convert

your

Radial

Arm

Saw

to

an

excellent tilting

arbor

drum

sander. (See Fig. 47.)

For

details

and

prices

of

No.

4000

and

4001

sanding

drum

sets see

ACCESSORIES

section

under

SANDING

DISCS

AND

DRUMS.

To

convert

your

machine,

turn

the

motor

to

the vertical position. Insert

the

drum

sander

into

the

proper

sleeve

and

adaptor

No.

900-440. Screw this assembly into

the

rear

motor

shaft. Slide the

carriage

over

the

arbor

clearance

cutout

in the table

and use the elevating

crank

handle

to lower

the

drum

into this slot.

As the grit becomes

worn

on

the

sanding

drum,

lower it

further

into

the

arbor

clearance

cutout

to

bring

a new section

of

the

drum

into

play. Use 50

or

60 grit sleeves for rough

sanding

and

120 grit

or

finer

for finishing.

SURFACE

PLANING:

(FIGURE

48)

You

can

easily

convert

your

Radial

Arm

Saw

for use

as

a

surface

planer

by

purchasing

Toolkraft

rotary

surface

planer

No.

4060

and

adaptor

No.

900-440. See

ACCESSORIES

section

under

PLANER

and

ADAPTORS.

To

convert

turn

the

motor

to the vertical position

and

install

rotary

planer

with

adaptor

in

the

same

manner

as

de-

scribed

under

routing

and

surface

sanding. (See Fig. 48.)

You

may

push the

cutter

over

your

material while shifting the material in

along

the fence until the

entire

surface

of

the material

is

planed.

You

may

also lock the

carriage

on

the

rotating

arm

and

feed the material

along

the fence

and

under

the

planer. When you have planed

one

strip off

the material, unlock

the

carriage

clamp,

slide the

cutting

head back

to the edge

of

the first

cut

and

repeat the

operation

until the

entire

surface

is

planed.

The

amount

of

stock which you

can

remove in

one

rass

is

determined by

the

density

of

the material you

are

working

with.

You may plane

up

to l/S" off soft material in

one

pass.

For

hard

wood

adjust the

cutter

up

or

down

as necessary to get full working

capacity

from the

motor

without

overloading

it.

DRUM SANDING

SURFACE

PLANING

FIGURE

47

FIGURE

48

-Page

17-

Loading...

Loading...