DRILLING

BUFFING

JOINTING

FIGURE

49

FIGURE

50

FIGURE

51

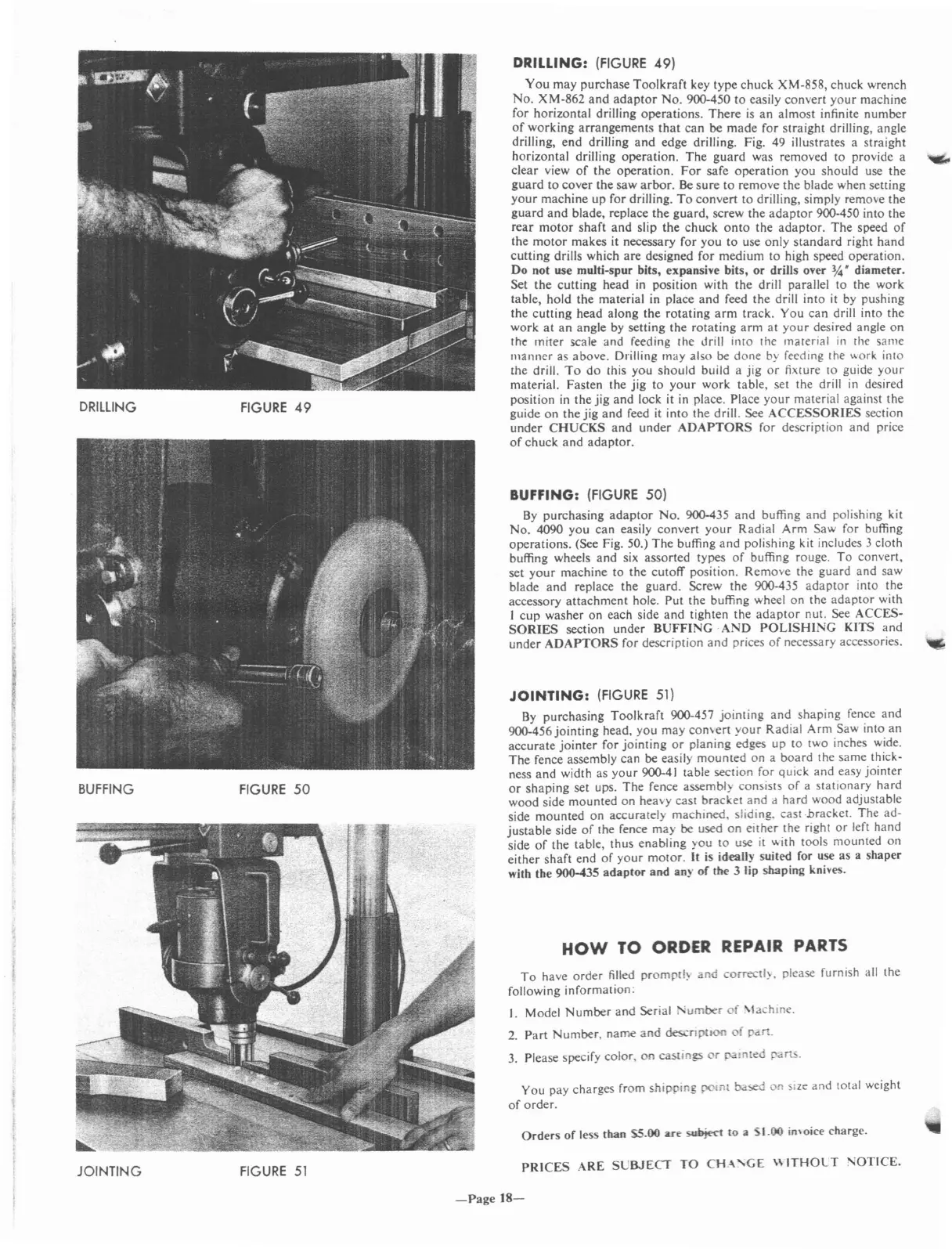

DRILLING:

(FIGURE

49)

You

may purchase

Toolkraft

key type chuck XM-858, chuck wrench

No. XM-862

and

adaptor

No. 900-450

to

easily convert

your

machine

for horizontal drilling operations.

There

is

an

almost infinite number

of

working arrangements

that

can be

made

for straight drilling, angle

drilling, end drilling

and

edge drilling. Fig. 49 illustrates a straight

horizontal drilling operation.

The

guard

was removed to provide a

clear view

of

the operation.

For

safe operation you should use the

guard

to

cover

the saw

arbor.

Be

sure

to

remove the blade when setting

your

machine up for drilling.

To

convert to drilling, simply remove the

guard

and

blade, replace the guard, screw the

adaptor

900-450 into the

rear

motor

shaft

and

slip

the

chuck

onto

the

adaptor.

The

speed

of

the

motor

makes it necessary for you

to

use only

standard

right hand

cutting

drills which are designed for medium to high speed operation.

Do not use multi-spur bits, expansive bits, or drills over

¥.!.

diameter.

Set the cutting head

in

position with the drill parallel to the work

table, hold the material in place

and

feed the drill into it by pushing

the cutting head along the

rotating

arm

track. You can drill into the

work

at

an

angle by setting the

rotating

arm

at

your

desired angle on

th~

miter scale and feeding the drill into the material

in

the same

manner

as above. Drilling

ll10y

also

be

done

by

feeding the work into

the drill.

To

do

this you should build a jig

or

fixlure

10

guide

your

material. Fasten the jig

to

your

work table, set the drill

in

desired

position

in

the

jig

and

lock it in place. Place

your

material against the

guide on the jig

and

feed it into the drill. See

ACCESSORIES

section

under

CHUCKS

and

under

ADAPTORS

for description and price

of

chuck

and

adaptor.

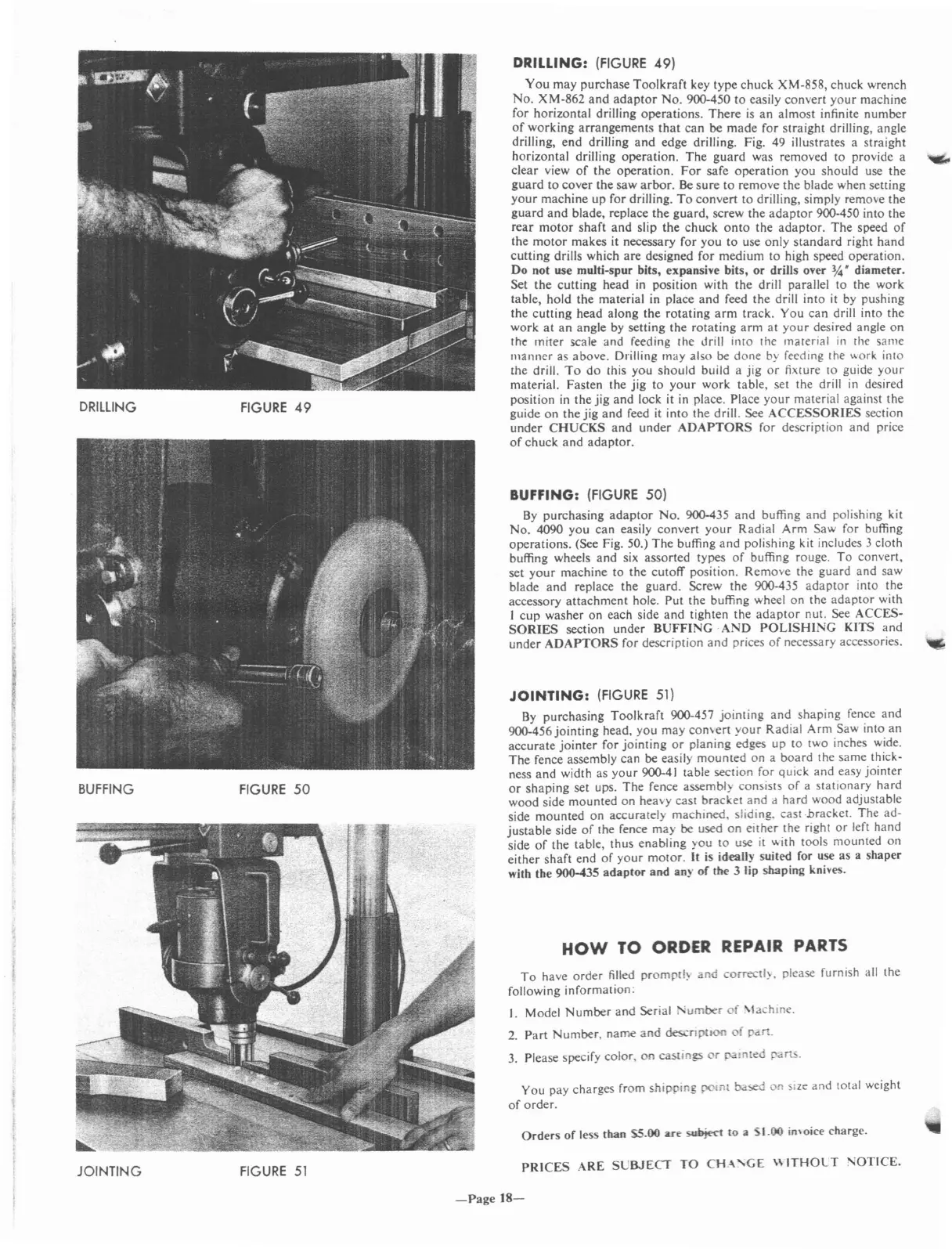

BUFFING:

(FIGURE

50)

By

purchasing

adaptor

No. 900-435

and

buffing

and

polishing kit

No. 4090 you can easily convert

your

Radial Arm Saw for buffing

operations. (See Fig. 50.)

The

buffing

and

polishing kit includes 3 cloth

buffing wheels

and

six assorted types

of

buffing rouge.

To

convert,

set

your

machine to the cutoff position. Remove the guard and saw

blade and replace the guard. Screw

the

900-435

adaptor

into the

accessory attachment hole. Put the buffing wheel on the

adaptor

with

I

cup

washer on each side

and

tighten the

adaptor

nut. See ACCES-

SORIES

section under

BUFFING

-

AND

POLISHING

KITS and

under

ADAPTORS

for description

and

prices

of

necessary accessories.

JOINTING:

(FIGURE

51)

By

purchasing Toolkraft 900-457

jointing

and

shaping fence

and

900-456 jointing head, you may convert

your

Radial Arm Saw into an

accurate

jointer

for jointing

or

planing edges up

to

two inches wide.

The

fence assembly can be easily

mounted

on a board the same thick-

ness

and

width as

your

900-41 table section for quick and easy jointer

or

shaping set ups. The fence assembly consists

of

a stationary hard

wood side mounted

on

heavy cast bracket

and

d hard wood adjustable

side mounted on accuratelv machined. sliding. cast-bracket. The ad-

justable side

of

the fence

~ay

be

used

on

eith~r

the right

or

left hand

side

of

the table, thus enabling you

to

use it

"ith

100is mounted

on

either shaft end

of

your

motor.

It

is

ideaU)' suited for use as a shaper

with the

900-435

adaptor

and an)'

of

the 3 lip shaping knives.

HOW

TO ORDER REPAIR

PARTS

To

have order filled

promptl~

and

correctl~.

please furnish all the

following information:

I. Model

Number

and Serial

1'umber

of

\Ia

-hine.

2.

Part

Number, name

and

descnplloo

of

part.

3. Please specify color,

on

castings

or

J:"!lnted

parts.

You pay charges from shipping

p0lnl

based

on

Size

and total weight

of

order.

Orders

of

less than

SS.OO

are

su~

to a

SI.OO

in'oice charge.

PRICES

ARE

SL'BJECT

TO

CH

-\

'GE

\\

ITHOL

T

NOTICE.

-Page

18-

Loading...

Loading...