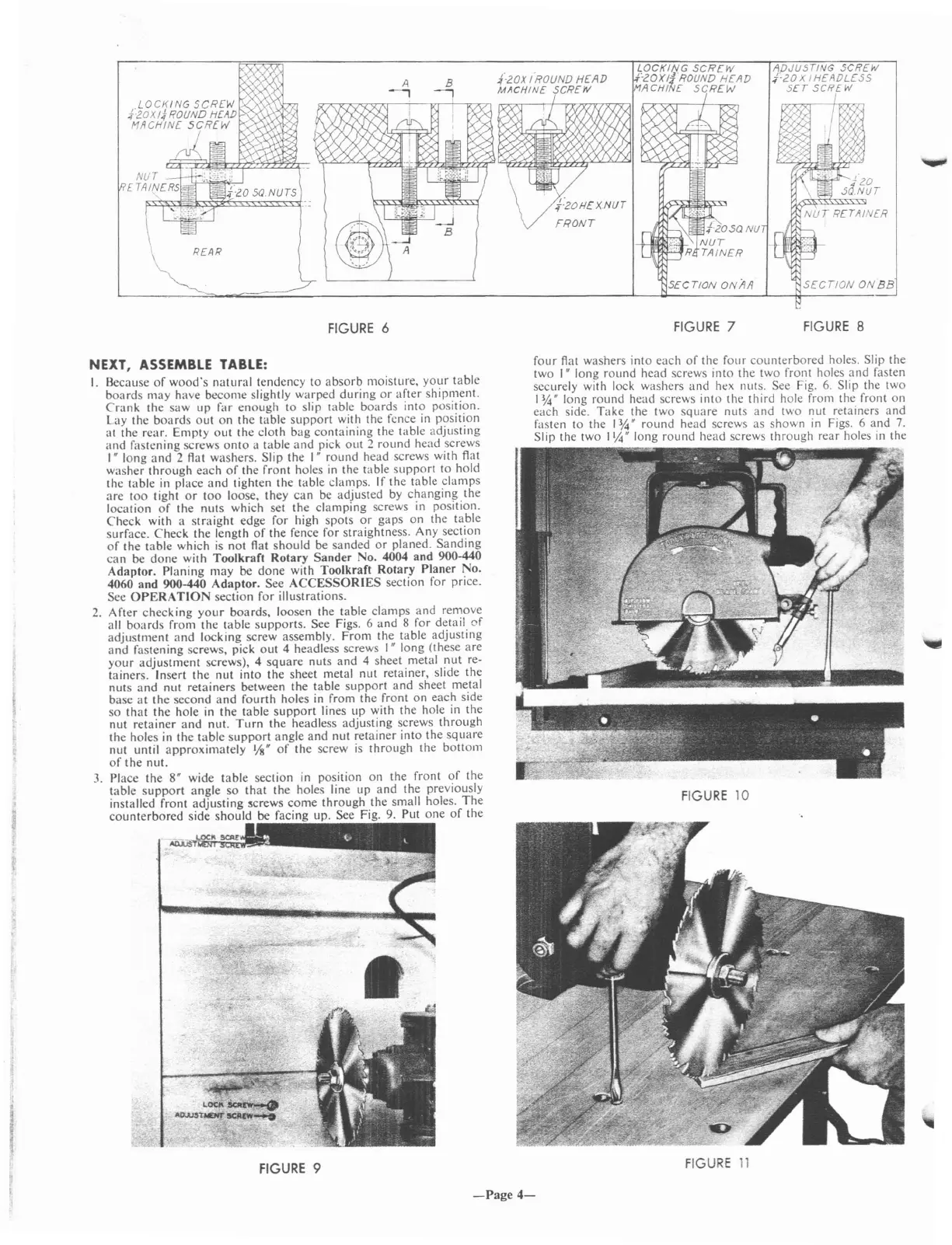

FIGURE

6

FIGURE

7

ADJUSTING

SCREW

;{zox I

HE

ADLE

SS

SET

SCREW

SECTION

ON

BE

FIGURE

8

NEXT,

ASSEMBLE

TABLE:

I.

Because

of

wood's

natural

tendency to

absorb

moisture,

your

table

boards

may

have become slightly warped

during

or

after

shipment.

Crank

the

saw

up far

enough

to slip table

boards

into position.

Lay the

boards

out

on

the table

support

with the fence

in

position

at the rear.

Empty

out

the cloth

bag

containing

the table adjusting

and

fastening screws

onto

a table

and

pick

out

:2

round

head screws

'"

long

and

2 flat washers. Slip the I"

round

head screws with flat

washer

through

each

of

the

front

holes

in

the table

support

to hold

the table in place

and

tighten the table clamps. If

the

table

clamps

are

too

tight

or

too

loose, they

can

be adjusted by

changing

the

location

of

the

nuts

which set the clamping screws in position.

Check

with a

straight

edge for high spots

or

gaps

on

the table

surface.

Check

the length

of

the fence for straightness. Any section

of

the table which

is

not flat

should

be sanded

or

planed.

Sanding

can

be

done

with

Toolkraft

Rotary

Sander

No. 4004 and 900-440

Adaptor.

Planing

may

be

done

with Toolkraft

Rotary

Planer

No.

4060 and 900-440

Adaptor.

See

ACCESSORIES

section for price.

See

OPERATION

section for illustrations.

2.

After

checking

your

boards, loosen the table clamps and remove

all

boards

from the table

supports.

See Figs. 6

and

8 for detail

of

adjustment

and

locking screw assembly.

From

the table adjusting

and

fastening screws, pick

out

4 headless screws

I"

long (these are

your

adjustment

screws), 4

square

nuts

and

4 sheet metal

nut

re-

tainers. Insert

the

nut into

the

sheet metal nut retainer, slide the

nuts

and

nut retainers between

the

table

support

and

sheet metal

base

at

the second

and

fourth

holes in from

the

front

on

each side

so

that

the

hole in the table

support

lines up with the hole in the

nut

retainer

and

nut.

Turn

the headless adjusting screws

through

the

holes in

the

table

support

angle

and

nut retainer into the

square

nut until

approximately

l/S"

of

the

screw

is

through

the

bottom

of

the

nut.

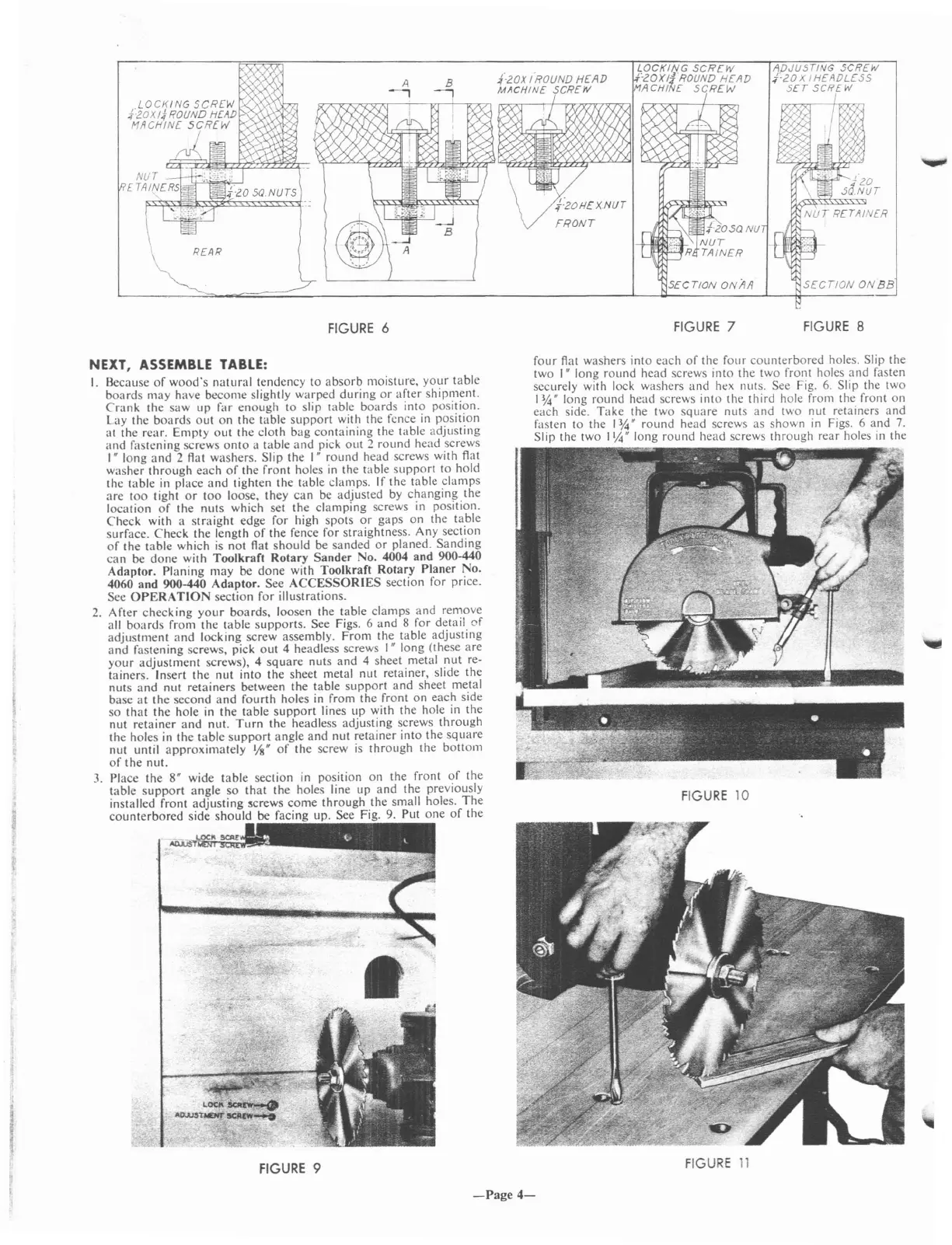

3.

Place the 8" wide table section

in

position

on

the front

of

the

table

support

angle

so

that

the holes line up

and

the previously

installed front

adjusting

5crews

come

through

the small holes.

The

counterbored

side

should

be facing up. See Fig.

9.

Put

one

of

the

FIGURE

9

four

Aat

washers into each

of

the

four

counterbored

holes. Slip the

two I" long round head screws into the two front holes

and

fasten

securely with lock washers

and

ht:x

nuts. See Fig.

6.

Slip the two

I

~"

long

round

head screws into the third hole from the front

on

each side.

Take

the two

square

nuts

and

two nut retainers and

fasten to the

I~"

round

head screws as shown

in

Figs. 6 and

7.

Slip the two \1,4" long

round

head screws

through

rear holes

in

the

FIGURE

10

FIGURE

11

-Page

4-

Loading...

Loading...