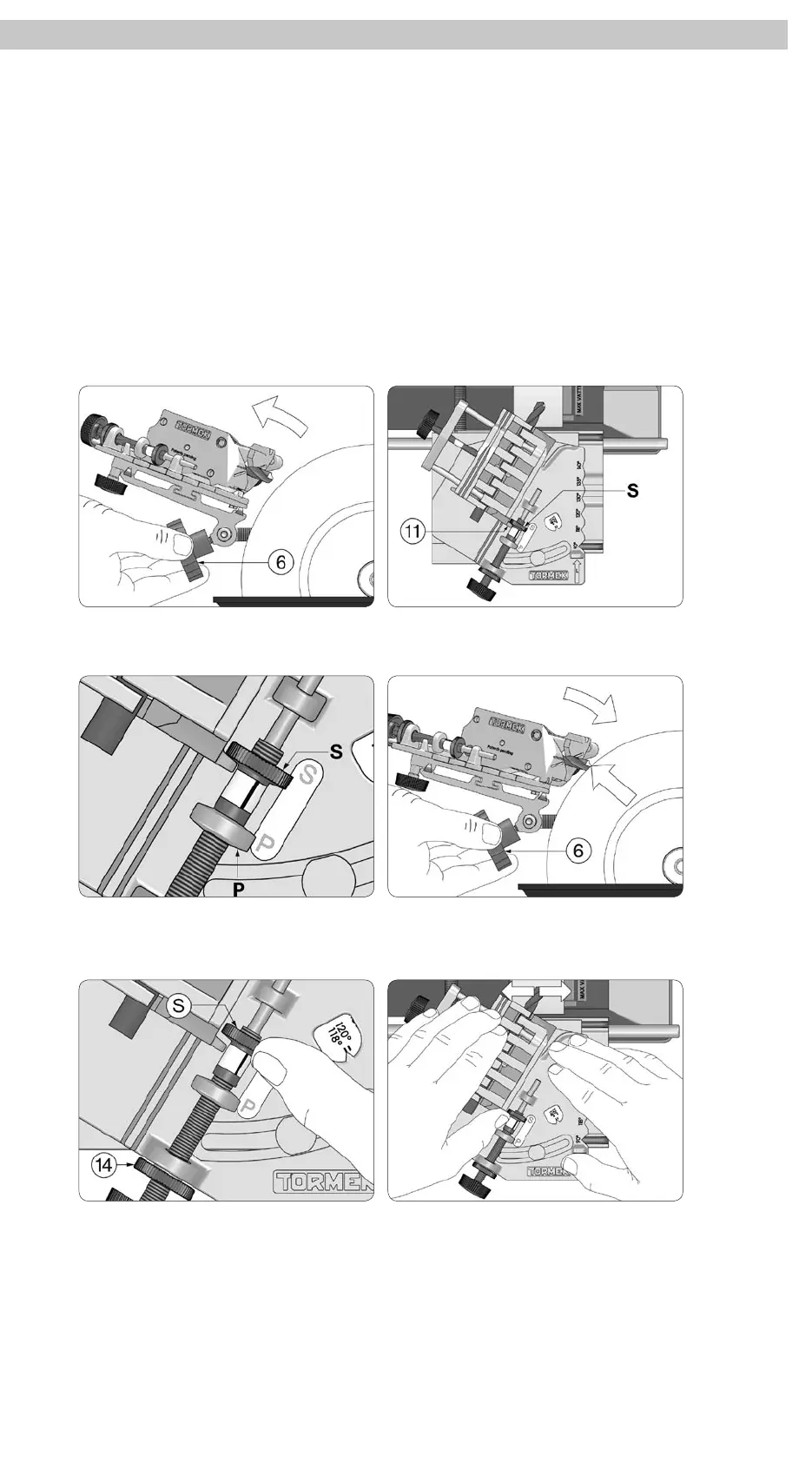

Screw the stop nut S forwards.

Start with 1½ turn for a 6 mm (¼") drill.

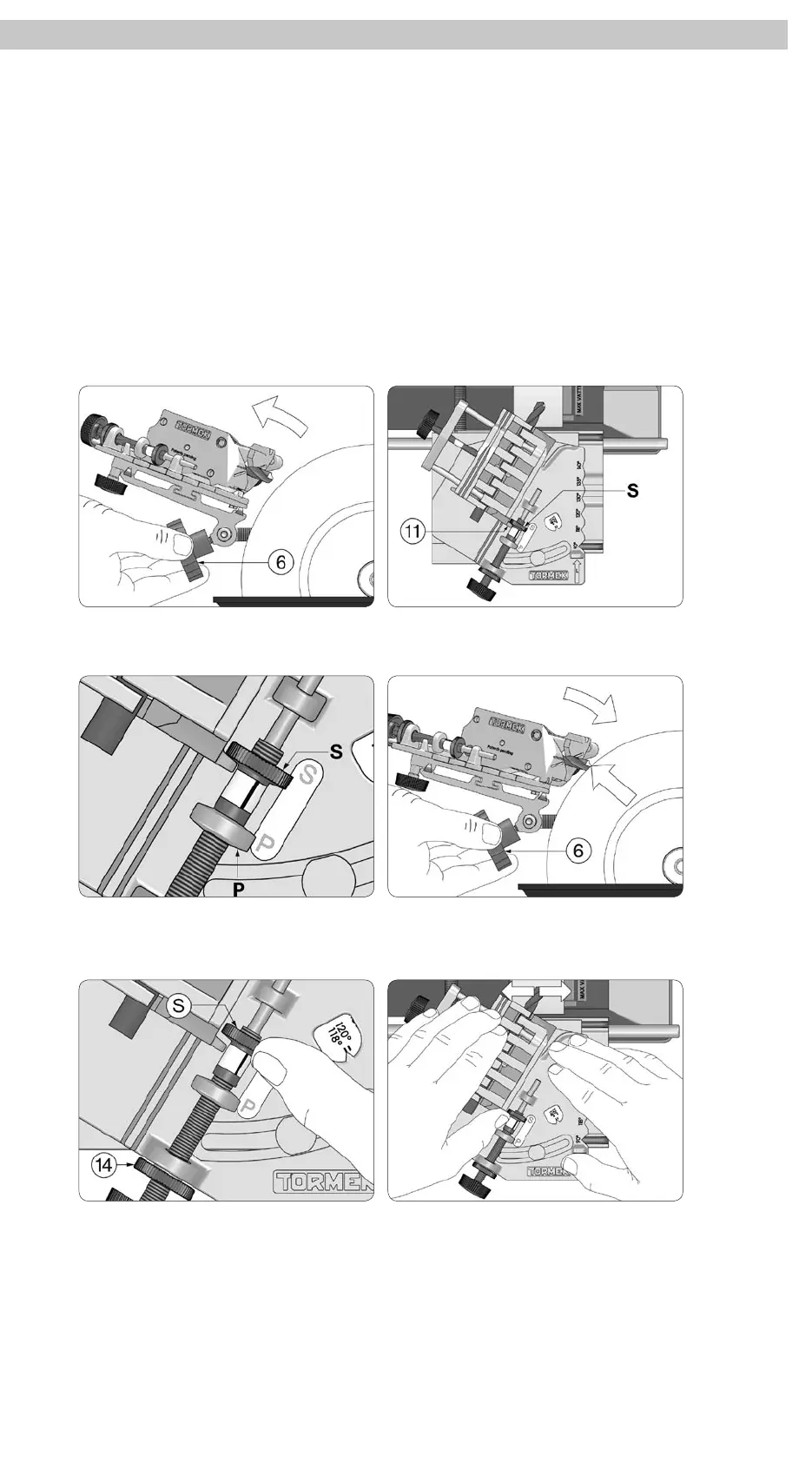

The setting screw should still be

locked with the locking nut (14).

Start the machine. Press the drill holder

towards the grindstone and start grinding

the first secondary facet. Move the guide

back and forth across the stone.

Tilt the base until the heel of the drill

touches the grindstone and lock it with

the wheel (6).

Loosen the wheel (6) and tilt the base

to an approx. horizontal position.

Lift and move the drill holder forwards so

that the lug (11) rests on the stop nut S.

Grind the Secondary Facets

and Create a 4-Facet Point

The stop nut S must be screwed

to touch the stop P.

The two primary facets meet and form a horizontal and at chisel edge without a

tip. This chisel edge is not the best since the drill will walk when you start drilling.

The chisel edge will also take a great deal of the axial force without actually cut-

ting and therefore creates much heat.

By grinding two secondary facets, the drill gets a 4-facet shape and a tip, which is

benecial for the function. The thrust force required is reduced as well as the heat

development which is most detrimental to the life of the drill bit. Furthermore a

4-facet point drills a straighter hole and will not walk.

Loading...

Loading...