Reaming an Existing Hole

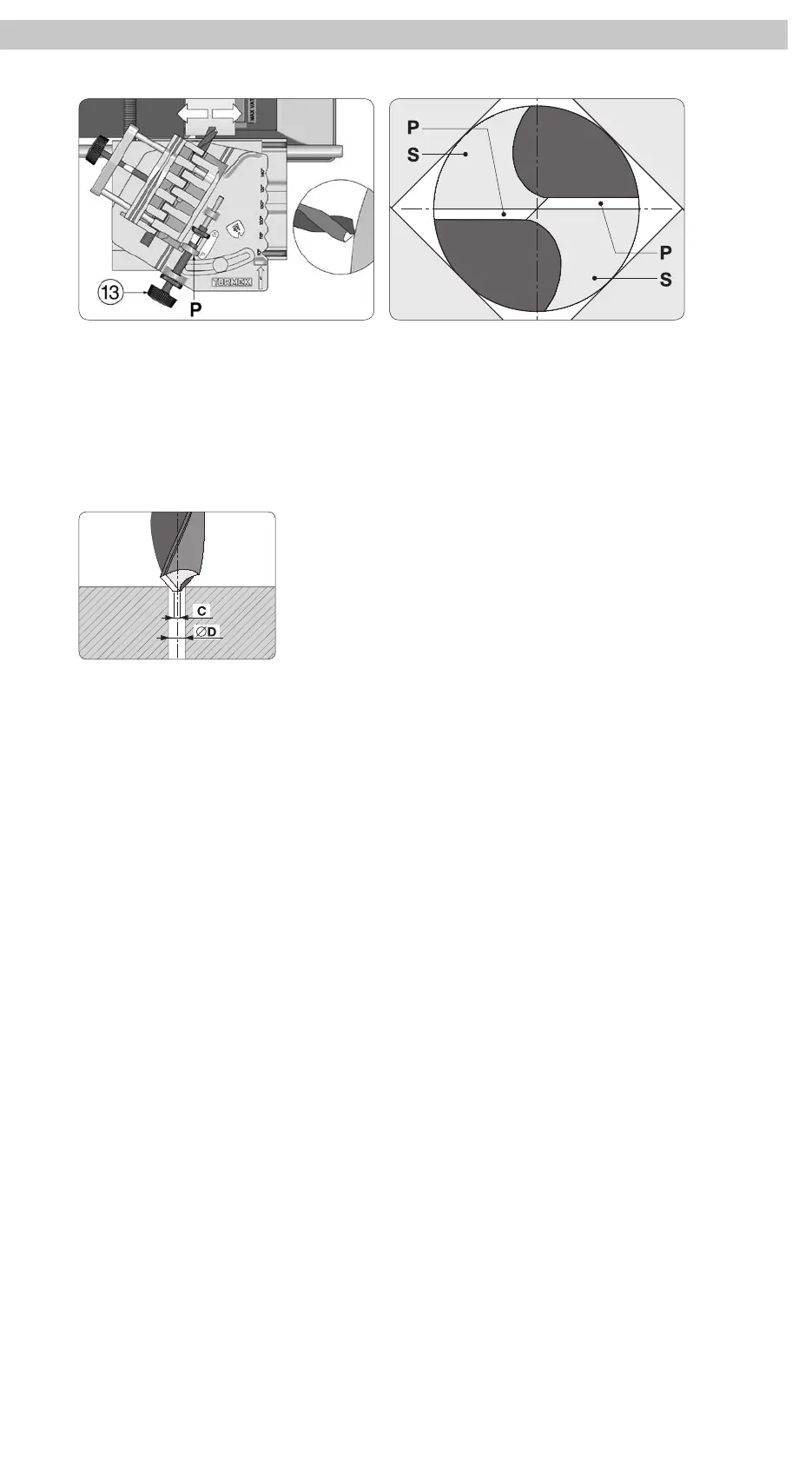

If you need to make an existing hole larger, you do not need to grind the secondary

facets. However the existing hole ∅ D must be larger than the chisel edge, C.

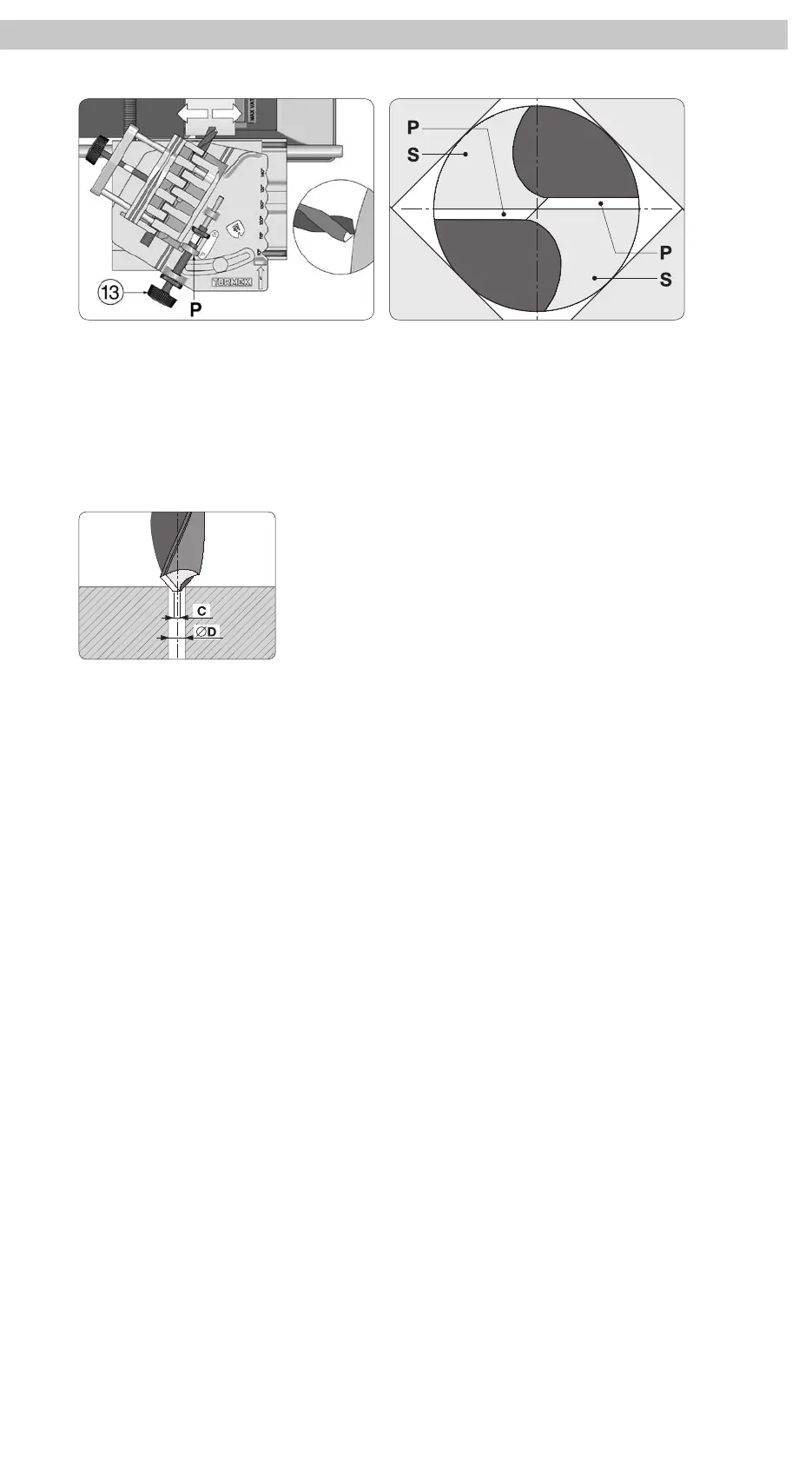

Turn the setting screw (13) lightly towards the grindstone and grind carefully

until the 4-facet point is established again.

Re-Sharpen Before the Drill Stops Working

Do not allow the drill to be worn so much that it starts to perform badly. Instead,

grind as soon as you notice that it does not work as it should, otherwise you need

to re-shape the point instead of just touching it up.

Keeping the Grindstone Active

If the efciency of the grindstone decreases during sharpening, you can easily

re-active it by using the coarse side of the Tormek Stone Grader SP-650. It brings

new grinding grains into operation and increases the efciency of the stone. The

Stone Grader can be especially useful when grinding thicker drills which have a

large grinding area.

Finer Surface

The Original Tormek Grindstone is 220 grit and gives a smooth cutting edge, ner

than from conventional high speed grinding. After you have ground the drill bit to

the right shape, you can use the ne side of the Tormek Stone Grader SP-650 to

grade the stone so that it corresponds to 1000 grit. Then you can further rene

the primary facets. The ner the surface of the edge – the better it will cut and the

longer it lasts.

When grinding smaller drills (up to approx. 6 mm or ¼") it is recommended that

you rene the grindstone from the beginning, since the stone otherwise can cut

too aggressively on a small drill.

Loading...

Loading...